| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Shredder |

|---|---|

| Brand Name: | Xrido |

| Model Number: | 1600 |

| Certification: | CE ISO TUV |

| MOQ: | 1 set |

| Payment Terms: | Negotiable |

| Delivery Time: | 2-30 Working Days |

| place of origin: | Henan, China |

| video outgoing-inspection: | Provided |

| machinery test report: | Provided |

| core components: | PLC, Engine, Bearing, Gearbox, Pressure vessel, motor, Gear, Pump |

| brand name: | Xrido |

| warranty: | 1 Year |

| material / metal processed: | Stainless Steel, Brass / Copper, Alloy, Carbon Steel, Aluminum |

| key selling points: | Competitive Price |

| Product name: | Waste Shredder Machine |

| Advantage: | Easy Operation High Efficiency |

| Machine Type: | Support Customization |

| Output: | Compact |

| Final product: | 1-10 Cm |

| MOTOR: | Famouse Brand |

| Application: | Metal Plastic Wood Bottle Film |

| After-sales Service Provided: | Video Technical Support |

| Condition: | New |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Applicable Industries: | Machinery Repair Shops, Building Material Shops, Manufacturing Plant |

| Company Info. |

| Henan Xrido Environmetal Protection Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Pyrolysis Tire Steel Wire Shredder Waste Steel Pre Shredder Scrap Metal Steel Wire Recycling Machine

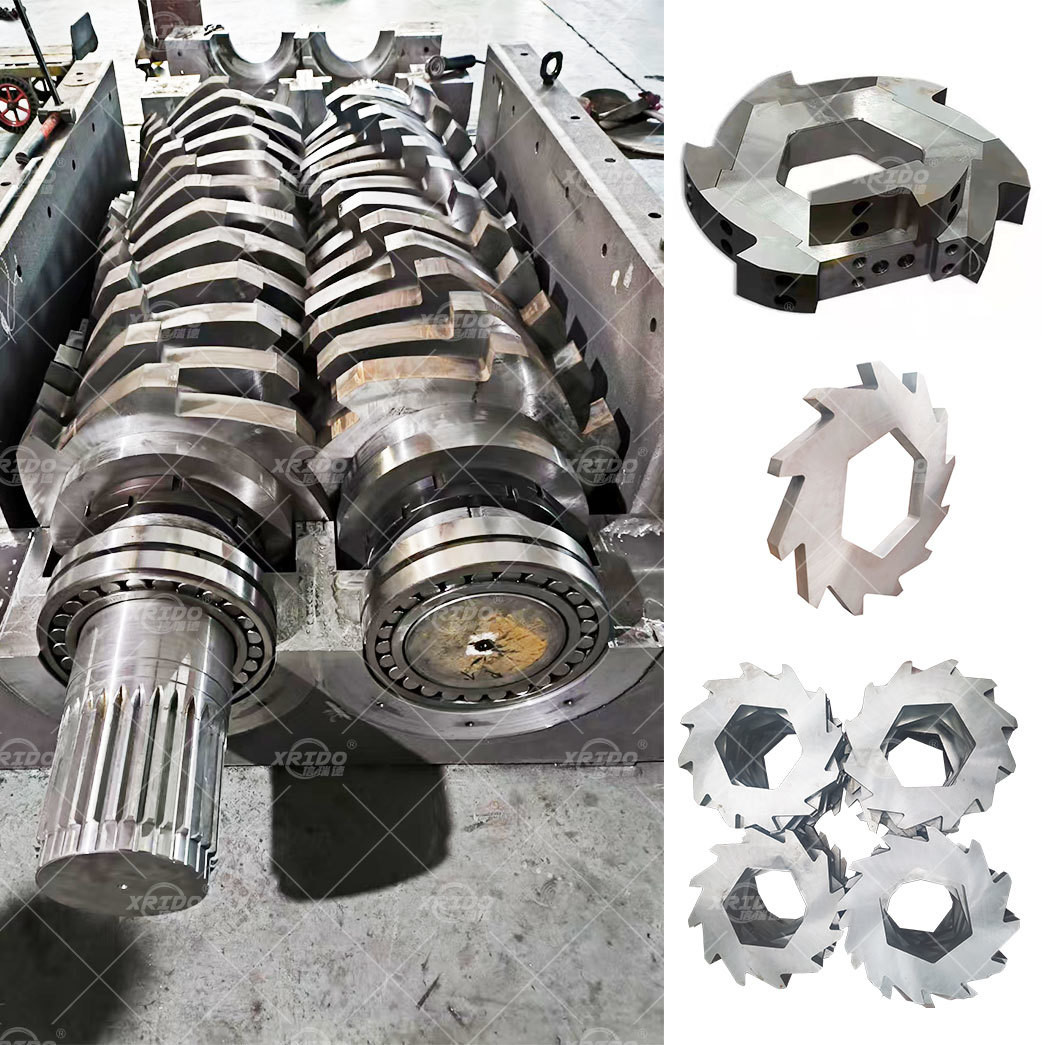

Working principle of tire steel wire shredder

1. Material transportation: After the waste tires are initially processed (such as cracking

and cutting), the clumps or strips containing steel wire are fed

into the shredder cavity through the feed port.

2. Mechanical crushing:

Double-axis/multi-axis structure: Through two (or more) main shafts equipped with staggered knives

rotating in opposite directions (or in the same direction), the

bite and shear force between the knives are used to forcibly tear

the steel wire and rubber. For example, the knives of the

double-axis shredder are arranged in a spiral shape, forming a

continuous shear surface when rotating, which can effectively cut

the steel wire.

Single-axis structure: Relying on the cooperation of the tool on a single main axis and

the fixed tool holder, the material is crushed through the

rotation, extrusion and shearing of the tool. The single-axis

design is often used to process loose tire wire materials.

3. Screening and separation: The crushed material passes through the bottom screen, and the

steel wire particles that meet the particle size requirements are

discharged, and the materials that do not meet the standards

continue to be crushed in the cavity; at the same time, some

equipment uses wind or vibration devices to assist in separating

steel wire and rubber debris to improve the recovery purity.

|  |

model | size(mm) | Shredder room(mm) | Blads(mm) | motor(k) | weight(kg) |

XD-600 | 2800×1300×1850 | 600×480 | 200 | 11×2 | 2200 |

XD-800 | 3000×1300×1850 | 800×480 | 200 | 15×2 | 2500 |

XD-1000 | 3300×1900×2200 | 1000×690 | 300 | 22×2 | 5200 |

XD-1200 | 3600×2000×2200 | 1200×690 | 300 | 30×2 | 6400 |

XD-1500 | 4180×2100×2400 | 1500×850 | 550 | 55×2 | 9000 |

XD-1800 | 5800×2400×3300 | 1800×1206 | 550 | 75×2 | 13600 |

XD-2000 | 6400×2700×3500 | 2000×1490 | 600 | 90×2 | 20100 |

XD-2500 | 7500×3200×3800 | 2500×1800 | 600 | 110×2 | 25000 |

Notes: 1. The number of blade claws, diameter, and thickness can be

customized according to the type of material and the size of the

discharge. 2. The output of the equipment will be different depending on the

type of material and the size of the discharge. 3. More information please contact us, we can custom the product on

your request. | |||||

The tire wire shredder mainly processes waste tire-related

materials containing steel wire, including:

Waste tire whole machine/fragments: tire cuts, tire rims (including high-hardness steel wire rims),

sidewalls, etc. that have not been cracked.

Pyrolysis tire steel wire: The remaining steel wire and rubber mixed mass after the waste

tire is thermally cracked or physically crushed, and the steel wire

is in a tangled or bonded state.

Tire wire waste: separately recycled tire wire bundles, steel cords (such as steel

cord fabrics in radial tires), or other rubber product waste

containing steel wire (such as steel hoses, conveyor belt scraps).

Other similar materials: metal-rubber composite materials with hardness and toughness close

to tire wire, such as seals and shock absorbers containing steel

wire, but the tool configuration needs to be adjusted according to

the equipment specifications.

|

|

|

|

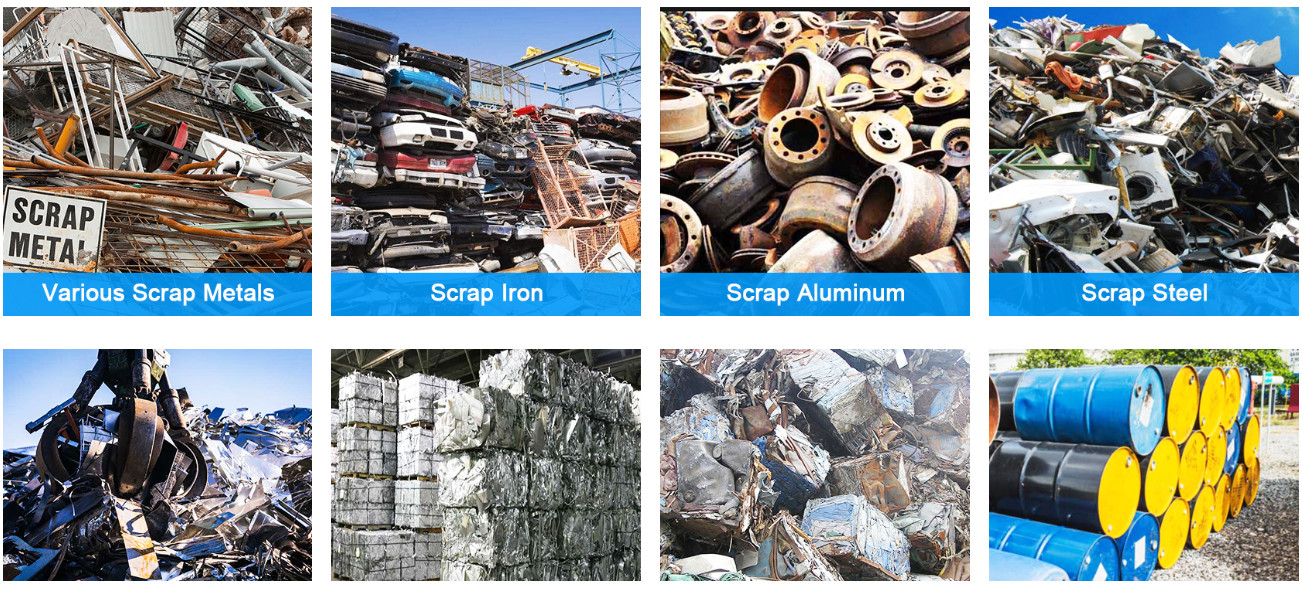

Scrap Metal Shredding & Crushing Line

1.metal recycling line adopts two-shaft metal shredder, hammer crusher for crushing the scrap metal.

2.Use Dust collector and special structures to remove the fine particle and dust during the crushing period.

3.The scrap metal recycling equipment separates the ferrous metal by a magnetic separator.

4.(Optional)Eddy current separator is adopted by the waste recycling machine to separate the non-ferrous metal from nonmetal materials.

Core equipment:Double-shaft shredder,Hammer crusher,Magnetic separator.

|

|

| Scrap Metal Shredder Sorting Line | Waste Aluminum Crushing Production Line |

|

|

| Aluminum Copper Crushing Sorting Line | UBC Aluminum Cans Decoating Machine |

|  |

|