| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Shredder |

|---|---|

| Brand Name: | Xrido |

| Model Number: | 1000 |

| Certification: | CE ISO TUV |

| MOQ: | 1 set |

| Payment Terms: | Negotiable |

| Delivery Time: | 2-30 Working Days |

| place of origin: | Henan, China |

| video outgoing-inspection: | Provided |

| machinery test report: | Provided |

| core components: | PLC, Engine, Bearing, Gearbox, Pressure vessel, motor, Gear, Pump |

| brand name: | Xrido |

| warranty: | 1 Year |

| material / metal processed: | Stainless Steel, Brass / Copper, Alloy, Carbon Steel, Aluminum |

| key selling points: | Competitive Price |

| Product name: | Waste Shredder Machine |

| Advantage: | Easy Operation High Efficiency |

| Machine Type: | Support Customization |

| Output: | Compact |

| Final product: | 1-10 Cm |

| MOTOR: | Famouse Brand |

| Application: | Metal Plastic Wood Bottle Film |

| After-sales Service Provided: | Video Technical Support |

| Condition: | New |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Applicable Industries: | Machinery Repair Shops, Building Material Shops, Manufacturing Plant |

| Company Info. |

| Henan Xrido Environmetal Protection Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Best Quality High Efficient Scrap Metal Shredder Waste Metal Crushing Machine Double Shaft Shredder Machine

Core features of scrap metal shredders:

1. High processing efficiency

- Wide range of processing capacity: Depending on the model, a

single device can process 1-50 tons of scrap metal per hour (such

as small machines are suitable for recycling stations, large

machines are suitable for smelters), which is more than 30% higher

than ordinary crushers.

- Continuous and stable operation: It adopts a large torque drive

system, can operate continuously for 24 hours, and the feeding is

smooth without jamming the machine, which is especially suitable

for batch processing of accumulated metal waste.

2. Excellent crushing effect

- Uniform fragment size: Through precise tool gap adjustment

(controllable within 5-100mm), the metal fragments after crushing

are regular in shape, without excessive crushing or large pieces

remaining, which is convenient for subsequent sorting,

transportation and smelting.

- Strong adaptability: It can process various types of metals with

a thickness of 0.1-10mm (such as thin iron sheets, thick steel

plates, aluminum alloy profiles, copper cables, etc.), including

waste materials with rust, coatings or slight impurities.

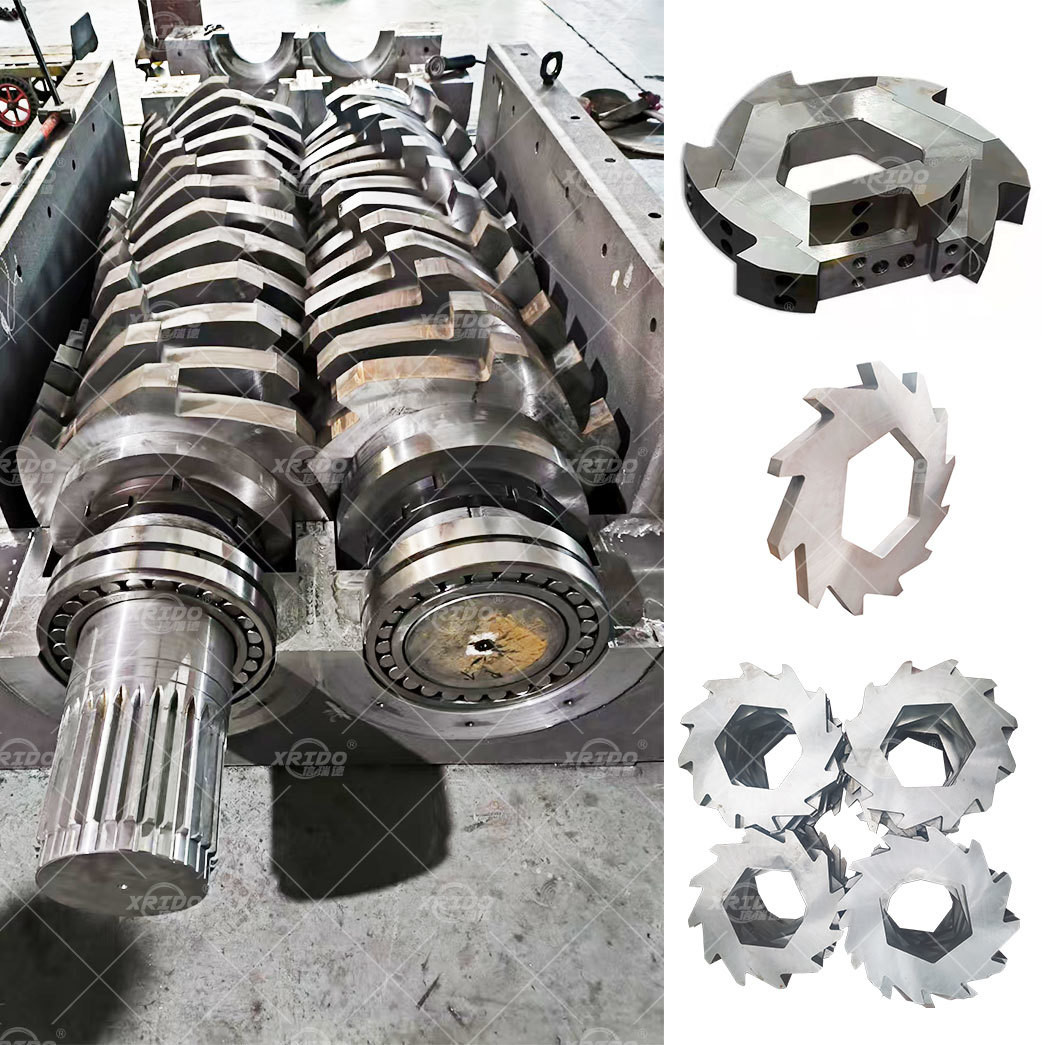

Scrap metal shredder tool system:

- Material upgrade: bimetallic composite materials (such as 45 steel for the blade

body to enhance toughness, and cemented carbide inlaid on the blade

edge) or high chromium cast iron (Cr26), with a hardness of

HRC60-65, and wear resistance is 2-3 times higher than that of

ordinary tools, and can handle high-hardness alloy metals.

- Structural optimization: The tools are "spirally staggered", and the blade edge adopts an

"eagle beak" or "step" design to increase the contact area with the

material and improve shearing efficiency; some high-end models

support two-way rotation of the tool to extend the wear cycle of

the single-sided blade edge.

Product parameters:

model | size(mm) | Shredder room(mm) | Blads(mm) | motor(k) | weight(kg) |

XD-600 | 2800×1300×1850 | 600×480 | 200 | 11×2 | 2200 |

XD-800 | 3000×1300×1850 | 800×480 | 200 | 15×2 | 2500 |

XD-1000 | 3300×1900×2200 | 1000×690 | 300 | 22×2 | 5200 |

XD-1200 | 3600×2000×2200 | 1200×690 | 300 | 30×2 | 6400 |

XD-1500 | 4180×2100×2400 | 1500×850 | 550 | 55×2 | 9000 |

XD-1800 | 5800×2400×3300 | 1800×1206 | 550 | 75×2 | 13600 |

XD-2000 | 6400×2700×3500 | 2000×1490 | 600 | 90×2 | 20100 |

XD-2500 | 7500×3200×3800 | 2500×1800 | 600 | 110×2 | 25000 |

Notes: 1. The number of blade claws, diameter, and thickness can be

customized according to the type of material and the size of the

discharge. 2. The output of the equipment will be different depending on the

type of material and the size of the discharge. 3. More information please contact us, we can custom the product on

your request. | |||||

|

|

Reliable and durable recycling technologies for material separation and recovery,treatment of various types of solid waste and metal scrap. Metal recycling can benefit your Enhance and economic value , Help you improve recycling eliminate landfilling of waste.

With XRIDO’s ready-to-use spare parts library , you gain peace of mind through seamless maintenance and reduced downtime.

|  |  |

Scrap Metal Shredding & Crushing Line

1.metal recycling line adopts two-shaft metal shredder, hammer crusher for crushing the scrap metal.

2.Use Dust collector and special structures to remove the fine particle and dust during the crushing period.

3.The scrap metal recycling equipment separates the ferrous metal by a magnetic separator.

4.(Optional)Eddy current separator is adopted by the waste recycling machine to separate the non-ferrous metal from nonmetal materials.

Core equipment:Double-shaft shredder,Hammer crusher,Magnetic separator.

|

|

| Scrap Metal Shredder Sorting Line | Waste Aluminum Crushing Production Line |

|

|

| Water Radiator Crushing Sorting Line | UBC Aluminum Cans Decoating Machine |

|

|

|

|