| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Shredder |

|---|---|

| Brand Name: | Xrido |

| Model Number: | 1000 |

| Certification: | CE ISO TUV |

| MOQ: | 1 set |

| Payment Terms: | Negotiable |

| Delivery Time: | 2-30 Working Days |

| place of origin: | Henan, China |

| video outgoing-inspection: | Provided |

| machinery test report: | Provided |

| core components: | PLC, Engine, Bearing, Gearbox, Pressure vessel, motor, Gear, Pump |

| brand name: | Xrido |

| warranty: | 1 Year |

| material / metal processed: | Stainless Steel, Brass / Copper, Alloy, Carbon Steel, Aluminum |

| key selling points: | Competitive Price |

| Product name: | Waste Shredder Machine |

| Advantage: | Easy Operation High Efficiency |

| Machine Type: | Support Customization |

| Output: | Compact |

| Final product: | 1-10 Cm |

| MOTOR: | Famouse Brand |

| Application: | Metal Plastic Wood Bottle Film |

| After-sales Service Provided: | Video Technical Support |

| Condition: | New |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Applicable Industries: | Machinery Repair Shops, Building Material Shops, Manufacturing Plant |

| Company Info. |

| Henan Xrido Environmetal Protection Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Scrap Barrel Shredder Iron Barrel Shredder For Metal Recycling Plant Scrap Metal Shredder Pre Shredder

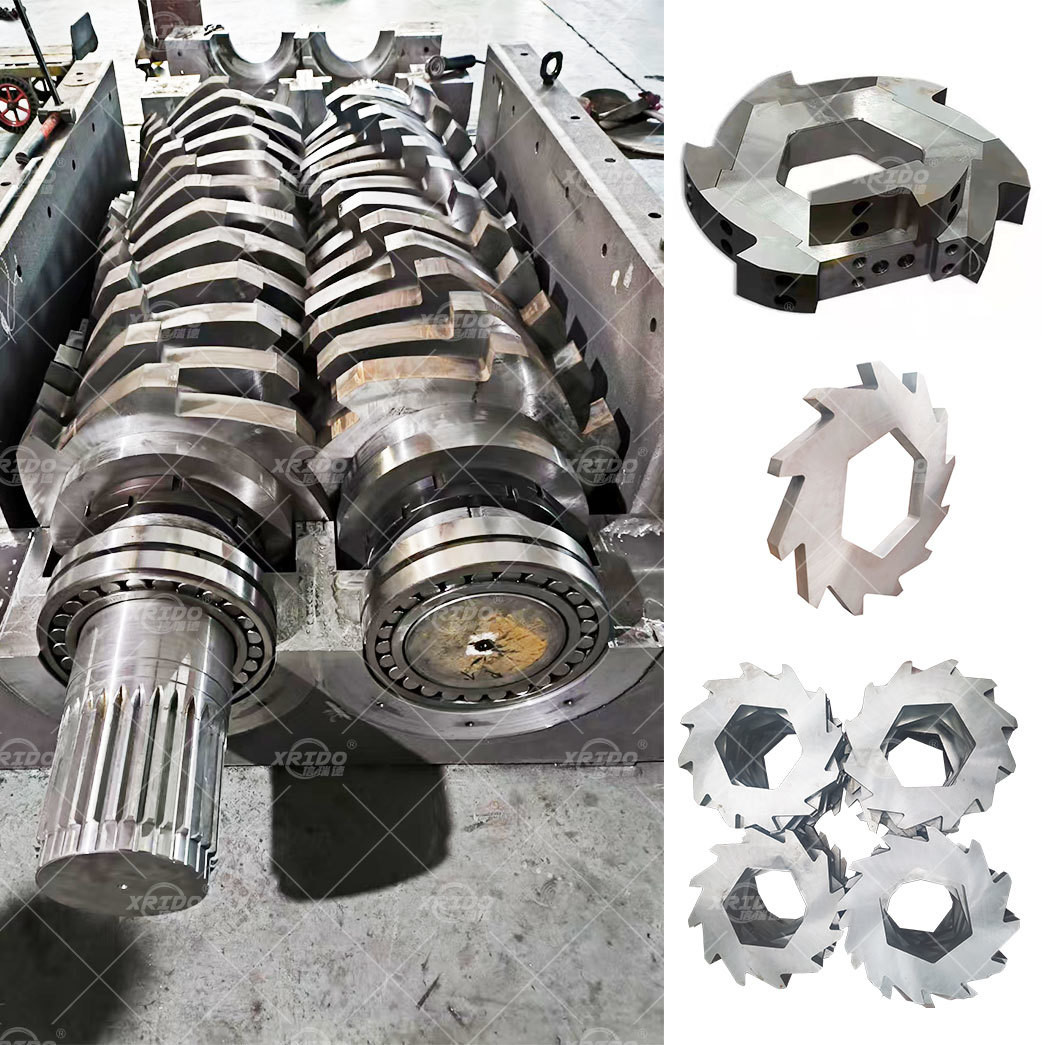

Working principle of barrel shredder

The core principle of barrel shredder is to achieve material

crushing through the shearing, tearing and extrusion of the cutter.

The specific process is as follows:

1. The drive system drives the knife shaft to rotate: the equipment is driven by the motor through the reducer to drive

two (or more) parallel knife shafts to rotate in opposite

directions (the speed is usually 50-200r/min, adjusted according to

the thickness of the barrel).

2. Material enters the crushing chamber: The waste iron barrel enters the crushing chamber between the

knife shafts through the feed port (manually or by conveyor belt).

3. Knife shearing and tearing: The knife shaft is equipped with staggered shredders (distributed

in spiral or block shape), and the knife edges are sharp and hard.

When the iron barrel contacts the knife, it is "bitten" and

forcibly dragged by the rotating knife. Through staggered shearing,

edge tearing and knife shaft extrusion between the knives, the iron

barrel is gradually broken from the whole into irregular small

pieces (usually 5-50mm in size, which can be controlled by

adjusting the knife gap).

4. Discharging and screening: The broken iron barrel fragments are discharged through the screen

(or discharge port) below the knife shaft. If the fragment size

does not meet the requirements (too large), it will be intercepted

by the screen and returned to the crushing chamber to be shredded

again until it reaches the preset size.

Advantages of shredder knives:

The shredder knives are the core components of the iron barrel

shredder. Their performance directly affects the crushing

efficiency and equipment life. The main advantages are as follows:

The material is wear-resistant and has high hardness: It is usually made of **high-alloy tool steel** (such as Cr12MoV,

D2, SKD11, etc.) after forging and quenching. The hardness can

reach HRC58-62, which can withstand the high-intensity impact and

friction of the iron barrel metal and is not easy to break or wear.

Strong adaptability of structural design: The knives are mostly "claw-shaped" or "rectangular blade"

designs, and the blade angles are optimized (usually 30°-45°),

which can not only quickly bite the edge of the iron barrel, but

also avoid jamming through staggered shearing (especially suitable

for processing deformed and convex iron barrels).

Long service life and low maintenance cost: The knives adopt a modular design. A single knife can be replaced

separately after wear (no need to replace the knife shaft as a

whole), and the wear resistance is enhanced through surface

carburizing, nitriding and other processes. After a single

replacement, 10-30 tons of iron barrels can be processed (depending

on the thickness of the iron barrel).

High safety and wide adaptability: The knife and the knife shaft are firmly connected, and can handle

iron barrels with a thickness of 0.3-3mm (including industrial

barrels with reinforcement ribs). It is also highly compatible with

iron barrels with slight rust and paint residues, and is not easily

stuck by impurities.

Product parameters:

model | size(mm) | Shredder room(mm) | Blads(mm) | motor(k) | weight(kg) |

XD-600 | 2800×1300×1850 | 600×480 | 200 | 11×2 | 2200 |

XD-800 | 3000×1300×1850 | 800×480 | 200 | 15×2 | 2500 |

XD-1000 | 3300×1900×2200 | 1000×690 | 300 | 22×2 | 5200 |

XD-1200 | 3600×2000×2200 | 1200×690 | 300 | 30×2 | 6400 |

XD-1500 | 4180×2100×2400 | 1500×850 | 550 | 55×2 | 9000 |

XD-1800 | 5800×2400×3300 | 1800×1206 | 550 | 75×2 | 13600 |

XD-2000 | 6400×2700×3500 | 2000×1490 | 600 | 90×2 | 20100 |

XD-2500 | 7500×3200×3800 | 2500×1800 | 600 | 110×2 | 25000 |

Notes: 1. The number of blade claws, diameter, and thickness can be

customized according to the type of material and the size of the

discharge. 2. The output of the equipment will be different depending on the

type of material and the size of the discharge. 3. More information please contact us, we can custom the product on

your request. | |||||

|

|

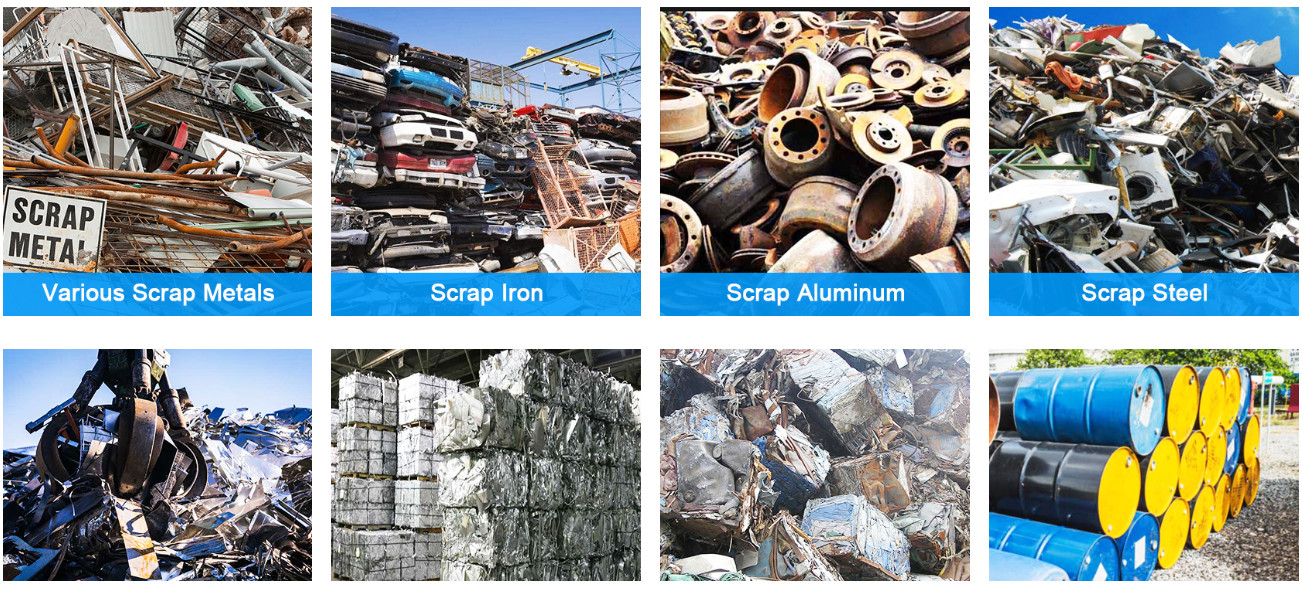

Reliable and durable recycling technologies for material separation and recovery,treatment of various types of solid waste and metal scrap. Metal recycling can benefit your Enhance and economic value , Help you improve recycling eliminate landfilling of waste.

With XRIDO’s ready-to-use spare parts library , you gain peace of mind through seamless maintenance and reduced downtime.

|  |  |

Scrap Metal Shredding & Crushing Line

1.metal recycling line adopts two-shaft metal shredder, hammer crusher for crushing the scrap metal.

2.Use Dust collector and special structures to remove the fine particle and dust during the crushing period.

3.The scrap metal recycling equipment separates the ferrous metal by a magnetic separator.

4.(Optional)Eddy current separator is adopted by the waste recycling machine to separate the non-ferrous metal from nonmetal materials.

Core equipment:Double-shaft shredder,Hammer crusher,Magnetic separator.

|

|

| Scrap Metal Shredder Sorting Line | Waste Aluminum Crushing Production Line |

|

|

| Water Radiator Crushing Sorting Line | UBC Aluminum Cans Decoating Machine |

|

|

|

|