| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Shredder |

|---|---|

| Brand Name: | Xrido |

| Model Number: | 1600 |

| Certification: | CE ISO TUV |

| MOQ: | 1 set |

| Payment Terms: | Negotiable |

| Delivery Time: | 2-30 Working Days |

| place of origin: | Henan, China |

| video outgoing-inspection: | Provided |

| machinery test report: | Provided |

| core components: | PLC, Engine, Bearing, Gearbox, Pressure vessel, motor, Gear, Pump |

| brand name: | Xrido |

| warranty: | 1 Year |

| material / metal processed: | Stainless Steel, Brass / Copper, Alloy, Carbon Steel, Aluminum |

| key selling points: | Competitive Price |

| Product name: | Waste Shredder Machine |

| Advantage: | Easy Operation High Efficiency |

| Machine Type: | Support Customization |

| Output: | Compact |

| Final product: | 1-10 Cm |

| MOTOR: | Famouse Brand |

| Application: | Metal Plastic Wood Bottle Film |

| After-sales Service Provided: | Video Technical Support |

| Condition: | New |

| Marketing Type: | Ordinary Product |

| Warranty of core components: | 1 Year |

| Applicable Industries: | Machinery Repair Shops, Building Material Shops, Manufacturing Plant |

| Company Info. |

| Henan Xrido Environmetal Protection Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Tire Stee Wire Shredder Wire Shredder Scrap Metal Shredder Waste Steel Pre Shredder For Scrap Metal

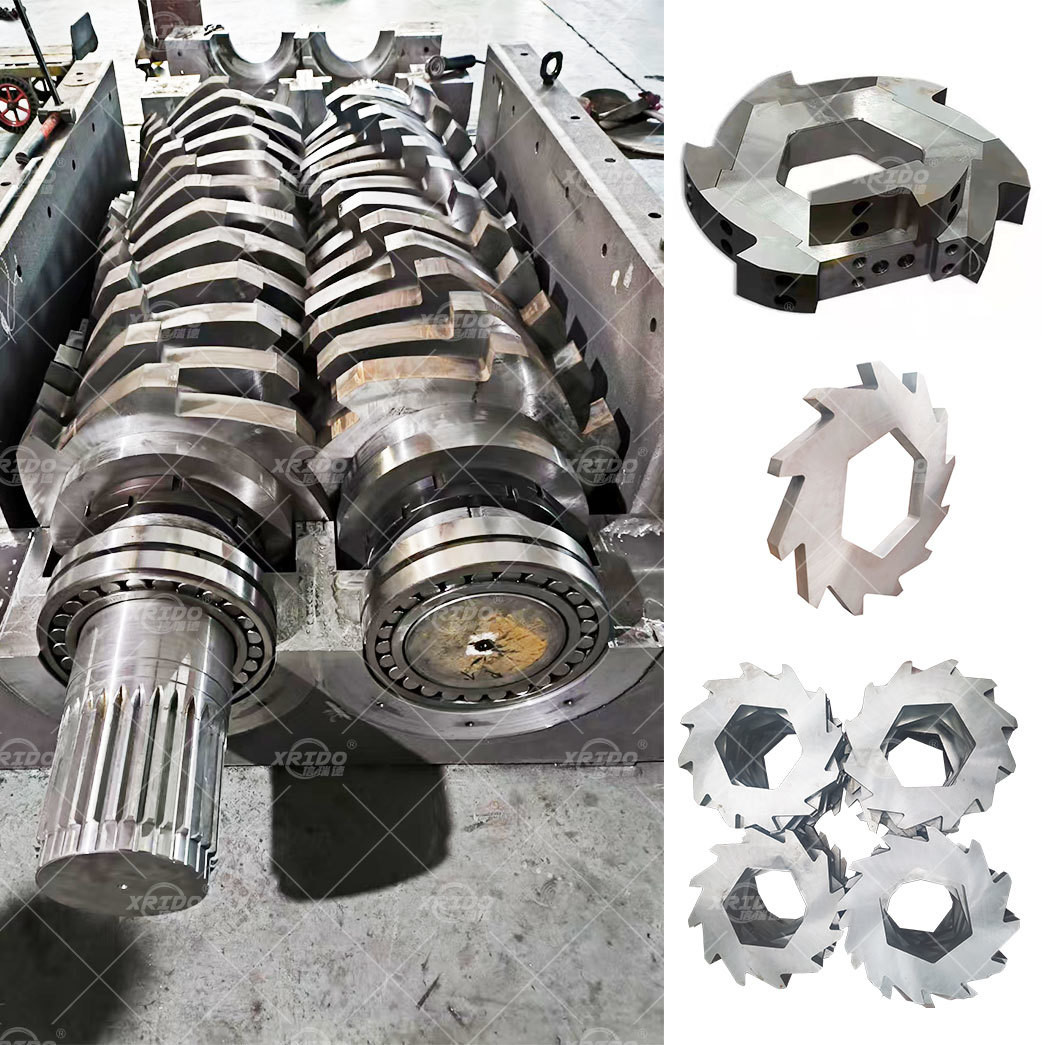

Structural composition of Tire Stee Wire Shredder:

Cutter system: It is the core component of the shredder, usually made of

high-strength, wear-resistant alloy steel or tungsten steel. For

example, the DGT series tire-specific shredder of Wuxi Digman

Environmental Protection Technology Co., Ltd. uses tungsten steel

cutters, which can be used on all four sides, and the life span is

more than 4-5 times that of ordinary cutters.

Transmission system: including motors, reducers, couplings, etc., to provide power for

the rotation of the cutter, so that the cutter can work at a

suitable speed and torque. Generally, imported reducers are used to

ensure stable and efficient operation of the machine, such as

Digman's single-shaft dual-drive method with large torque.

Frame and shell: used to support and fix the various parts of the shredder, and at

the same time play a protective role to prevent material splashing

and operator injuries. It is generally welded with high-strength

steel plates and has sufficient strength and stability.

|  |

model | size(mm) | Shredder room(mm) | Blads(mm) | motor(k) | weight(kg) |

XD-600 | 2800×1300×1850 | 600×480 | 200 | 11×2 | 2200 |

XD-800 | 3000×1300×1850 | 800×480 | 200 | 15×2 | 2500 |

XD-1000 | 3300×1900×2200 | 1000×690 | 300 | 22×2 | 5200 |

XD-1200 | 3600×2000×2200 | 1200×690 | 300 | 30×2 | 6400 |

XD-1500 | 4180×2100×2400 | 1500×850 | 550 | 55×2 | 9000 |

XD-1800 | 5800×2400×3300 | 1800×1206 | 550 | 75×2 | 13600 |

XD-2000 | 6400×2700×3500 | 2000×1490 | 600 | 90×2 | 20100 |

XD-2500 | 7500×3200×3800 | 2500×1800 | 600 | 110×2 | 25000 |

Notes: 1. The number of blade claws, diameter, and thickness can be

customized according to the type of material and the size of the

discharge. 2. The output of the equipment will be different depending on the

type of material and the size of the discharge. 3. More information please contact us, we can custom the product on

your request. | |||||

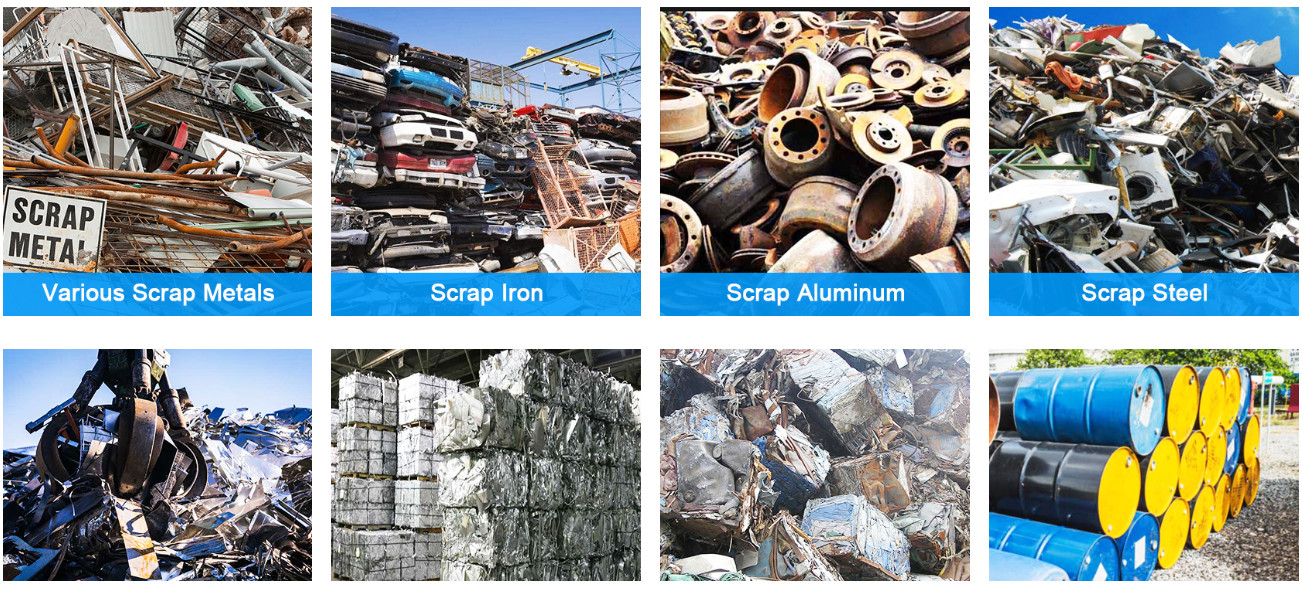

The tire wire shredder mainly processes waste tire-related

materials containing steel wire, including:

Waste tire whole machine/fragments: tire cuts, tire rims (including high-hardness steel wire rims),

sidewalls, etc. that have not been cracked.

Pyrolysis tire steel wire: The remaining steel wire and rubber mixed mass after the waste

tire is thermally cracked or physically crushed, and the steel wire

is in a tangled or bonded state.

Tire wire waste: separately recycled tire wire bundles, steel cords (such as steel

cord fabrics in radial tires), or other rubber product waste

containing steel wire (such as steel hoses, conveyor belt scraps).

Other similar materials: metal-rubber composite materials with hardness and toughness close

to tire wire, such as seals and shock absorbers containing steel

wire, but the tool configuration needs to be adjusted according to

the equipment specifications.

Reliable and durable recycling technologies for material separation and recovery,treatment of various types of solid waste and metal scrap. Metal recycling can benefit your Enhance and economic value , Help you improve recycling eliminate landfilling of waste.

With XRIDO’s ready-to-use spare parts library , you gain peace of mind through seamless maintenance and reduced downtime.

|

|

|

|

Scrap Metal Shredding & Crushing Line

1.metal recycling line adopts two-shaft metal shredder, hammer crusher for crushing the scrap metal.

2.Use Dust collector and special structures to remove the fine particle and dust during the crushing period.

3.The scrap metal recycling equipment separates the ferrous metal by a magnetic separator.

4.(Optional)Eddy current separator is adopted by the waste recycling machine to separate the non-ferrous metal from nonmetal materials.

Core equipment:Double-shaft shredder,Hammer crusher,Magnetic separator.

|

|

| Scrap Metal Shredder Sorting Line | Waste Aluminum Crushing Production Line |

|

|

| Aluminum Copper Crushing Sorting Line | UBC Aluminum Cans Decoating Machine |

|  |

|