| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Nickel Based Welding Wire |

|---|---|

| Brand Name: | Runlai |

| Model Number: | ERNiCrMo-4 |

| Certification: | CE,ROHS,ISO 9001 |

| Place of Origin: | China |

| MOQ: | 10 Kg |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300 tons per month |

| Delivery Time: | 20~40 Days |

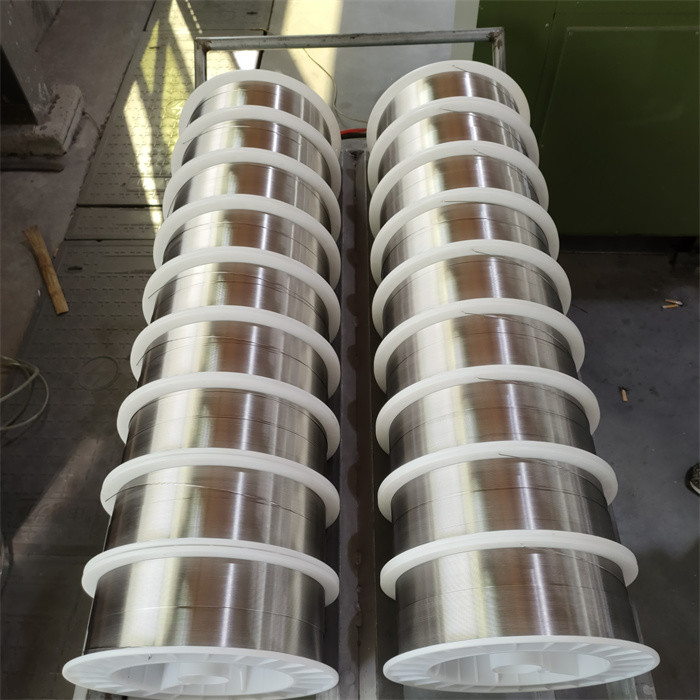

| Packaging Details: | Packed in Spool Carton box, Coil package with polybag,then in woodencase |

| Product Name: | ERNiCrMo-4 Welding Wire |

| Material: | Ni Cr |

| Size: | 1.0-2.4mm |

| Application: | Welding reactors, heat exchangers, pipelines and other equipment |

| Customized Support: | OEM, ODM, OBM |

| Use Type: | Mig Torch/Tig Torch |

| Yield Strength: | ≥420Mpa |

| Elongation: | ≥27% |

| Tensile Strength: | ≥760Mpa |

| Melting Point: | 1290-1350℃ |

| Standard: | AWS A5.14 ASME DIN |

| Company Info. |

| CHANGZHOU LIANGRU INTERNATIONAL TRADE CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

Monel Inconel Hasteloy Welding Wire Inconel 695 Wire Mesh

Areas of application:

1. Industrial process control: Thermocouple wire is widely used in

industrial process control systems. It is used to measure and

monitor temperature in manufacturing processes such as chemical

production, metal refining, food processing, and power generation.

2. HVAC (Heating, Ventilation, and Air Conditioning): Thermocouple

wire is employed in HVAC systems for temperature sensing and

control. It is used in thermostats, temperature controllers, and

heating/cooling systems to maintain desired temperatures in

residential, commercial, and industrial buildings.

3. Aerospace industry: Thermocouple wire finds application in the

aerospace industry for temperature measurement in aircraft engines,

combustion chambers, and critical components. It helps monitor and

control temperatures to ensure safe and efficient operation.

Advantages and Characteristics

Q&A

Q:Precautions for ERNiCrMo-4 welding wire when welding Hastelloy

C276

A:Surface cleaning: Before welding, the welding area must be

thoroughly cleaned of impurities such as oil, rust, and moisture to

ensure welding quality.

Welding parameter control: Use small wire energy for welding, and

it is recommended to use a lower inter pass temperature to avoid

material performance degradation caused by overheating.

Protective gas: Use high-purity argon gas for protection to ensure

the quality of the weld seam.

Welding method: Generally, tungsten inert gas welding (TIG) or gas

metal arc welding (GMAW) is used to ensure the stability of the

welding process and the quality of the weld seam.

Q:Welding temperature range of ERNiCrMo-4 welding wire

A:The welding temperature range of ERNiCrMo-4 welding wire is

usually between 1325-1370 ° C. In the actual welding process, the

specific welding temperature will be adjusted according to

different welding methods and equipment to ensure the best

performance of welding quality and material properties.

Q:Advantages of ERNiCrMo-4 welding wire compared to stainless steel

welding wire

A:Corrosion resistance: ERNiCrMo-4 welding wire has excellent

corrosion resistance, especially in corrosive environments

containing chlorides, acids, and alkalis, which can effectively

prevent pitting and crevice corrosion

High temperature performance: ERNiCrMo-4 welding wire can maintain

high strength and stability in high-temperature environments,

making it suitable for use in high-temperature conditions.

Welding performance: It has excellent melting performance and

welding process performance, beautiful weld formation, and

excellent mechanical properties of deposited metal. In contrast,

stainless steel welding wire may not perform as well as ERNiCrMo-4

welding wire in high temperature and corrosive environments.

|