| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Nickel Based Welding Wire |

|---|---|

| Brand Name: | Runlai |

| Model Number: | ERNiCu-7 |

| Certification: | CE,ROHS,ISO 9001 |

| Place of Origin: | China |

| MOQ: | 10 Kg |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300 tons per month |

| Delivery Time: | 20~40 Days |

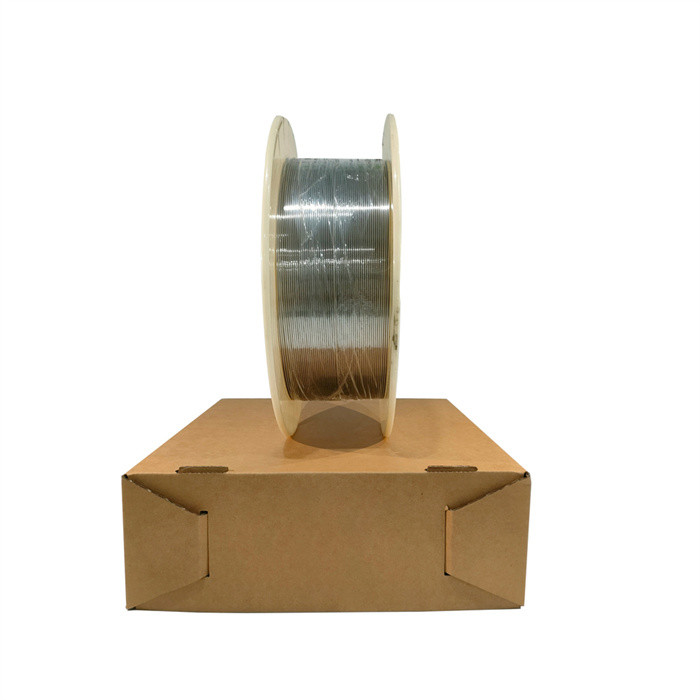

| Packaging Details: | Packed in Spool Carton box, Coil package with polybag,then in woodencase |

| Product Name: | ERNiCu-7 Welding Wire |

| Material: | Ni Cu |

| Size: | 1.0-2.4mm |

| Application: | Repair and maintenance of power generation equipment, surface welding |

| Customized Support: | OEM, ODM, OBM |

| Use Type: | Mig Torch/Tig Torch |

| Yield Strength: | 345 MPa |

| Elongation: | 30% |

| Tensile Strength: | 689 MPa |

| Melting Point: | 1370℃ |

| Criterion: | Aws A5.14, ASME 9 |

| Company Info. |

| CHANGZHOU LIANGRU INTERNATIONAL TRADE CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

Power Industry Inconel Alloy Wire Mesh Chromel KP and Nickel Alumel KN Monel Welding Wire

Type J Temperature Range:

* Thermocouple grade wire, -346 to 1,400F (-210 to 760C)

* Extension wire, 32 to 392F (0 to 200C)

Type J Accuracy (whichever is greater):

* Standard: +/- 2.2C or +/- .75%

* Special Limits of Error: +/- 1.1C or 0.4%

| Tensile Strength | 109 Ksi | 790 MPA |

| Yield Strength | 68 Ksi | 470 MPA |

| Elongation | 40-45% | |

| Density g/cm3 | 8.60 g/cm3 | |

| Melting Point ℃ | 1300-1360℃ | |

| Coefficient of Expansion. 21-93 Co, μm/m * Co | 11.90 |

Specific Applications

Advantages and Characteristics

Customization

This is a series of welding wire products including ERNiCrMo-3, ERNiCrMo-4, ERNiCrMo-13, ERNiCrFe-3, ERNiCrFe-7, ERNiCr-3, ERNiCr-7, ERNiCu-7 and ERNi-1.

Nickel welding wire is available in different grades and specifications depending on specific application requirements. Various nickel alloy welding wires (such as ERNiCr-3, ERNiCrMo-3, etc.) and pure nickel welding wires (such as ERNi-1, ERNi-2, etc.) can be selected according to specific alloy composition and performance requirements.

In short, nickel welding wire is an important welding material with excellent welding performance and adaptability. It plays an important role in various industrial fields, providing reliable welding solutions for manufacturing and maintaining high-quality metal structures.

Welding precautions

Q&A

Q:What is the welding performance of ERNiCu-7 nickel based welding

wire?

A:ERNiCu-7 nickel based welding wire has excellent welding process

performance, beautiful weld formation, outstanding mechanical

properties of deposited metal, and excellent resistance to pitting

corrosion, stress corrosion, and high-temperature oxidation.

Specifically, the weld metal formed using ERNiCu-7 welding wire has

similar properties to MONEL 400 alloy, high strength, and strong

corrosion resistance in various media, including seawater, salts,

and reducing acids. When using this welding rod to weld MONEL K-500

alloy, the strength is lower than that of the base metal because

the filler metal in the weld cannot produce age hardening effect.

Q:What is the strength of ERNiCu-7 welding wire when welding K-500

alloy?

A:When welding K-500 alloy with ERNiCu-7 welding wire, the filler

metal in the weld seam cannot produce age hardening effect, so the

strength is lower than that of the base metal.

Q:What is the welding temperature range of ERNiCu-7 welding wire in

the power industry?

A:The welding temperature range of ERNiCu-7 welding wire is generally

between 1100-1200 degrees Celsius.

|