| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Nickel Based Welding Wire |

|---|---|

| Brand Name: | Runlai |

| Model Number: | ERNiCrMo-13 |

| Certification: | CE,ROHS,ISO 9001 |

| Place of Origin: | China |

| MOQ: | 10 Kg |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union, MoneyGram |

| Supply Ability: | 300 tons per month |

| Delivery Time: | 20~40 Days |

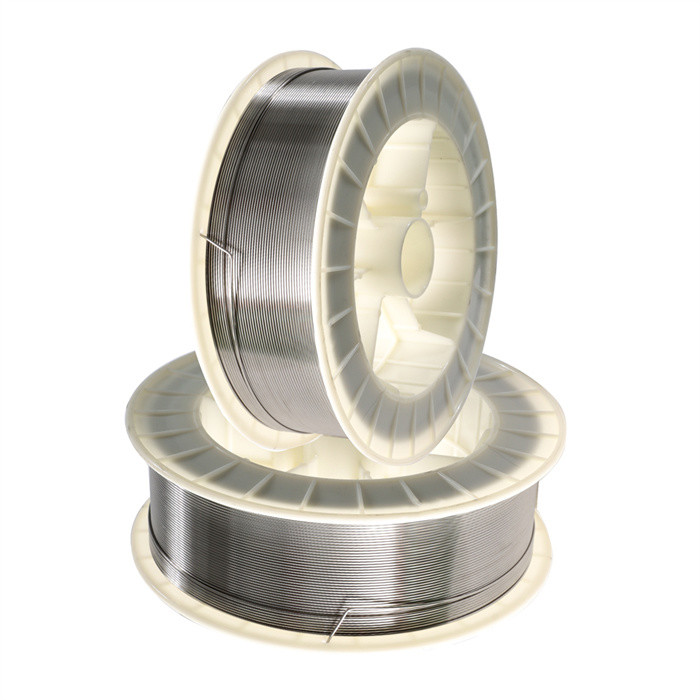

| Packaging Details: | Packed in Spool Carton box, Coil package with polybag,then in woodencase |

| Product Name: | ERNiCrMo-13 Welding Wire |

| Material: | Ni Cr Mo |

| Size: | 1.0-2.4mm |

| Application: | Welding nuclear reactors, welding high-temperature components |

| Customized Support: | OEM, ODM, OBM |

| Use Type: | Mig Torch/Tig Torch |

| Yield Strength: | ≥420Mpa |

| Elongation: | ≥27% |

| Tensile Strength: | ≥760Mpa |

| Melting Point: | 1290-1350℃ |

| Standard: | AWS A5.14 ASME DIN |

| Company Info. |

| CHANGZHOU LIANGRU INTERNATIONAL TRADE CO., LTD. |

| Verified Supplier |

| View Contact Details |

| Product List |

Inconel 625 Alloy Wire Mesh 1.2mm 1.6mm 2.4mm ERNiCrMo-13 Nickel Haynes 230/556/188

Duplex: 2205(UNS S31803/S32205),2507(UNS S32750),UNS S32760(Zeron 100),2304,904L

Others:253Ma,254SMo,654SMo,F50(UNSS32100)F60,F61,F65,1J22,N4,N6 etc

Alloy : Alloy 20/28/31

Hasteloy:HasteloyB/ -2/B-3/C22/C-4/S/ C276/C-2000/G-35/G-30/X/N/g

Hasteloy B / UNS N10001,Hasteloy B-2 / UNS N10665 / DIN W. Nr.

2.4617,Hasteloy C,

Hasteloy C-4 / UNS N06455 / DIN W. Nr. 2.4610,Hasteloy C-22 / UNS

N06022 / DIN W. Nr. 2.4602,

Hasteloy C-276 / UNS N10276 / DIN W. Nr. 2.4819,Hasteloy X / UNS

N06002 / DIN W. Nr. 2.4665

Haynes: Haynes 230/556/188

Parameter

| MIG | (15kg/spool), | Size |

| 0.8 1.2 2.4 3.2mm | ||

| TIG | (5kg/box),Strip |

ERNiCrMo-13

| C | Mn | Fe | P | S | Si | Cu | Ni | Co | Al | Ti | Cr | Nb+Ta | Mo | V | W | Rest |

| 0.01 | 0.5 | 1.5 | 0.015 | 0.005 | 0.1 | N/A | Rest | 0.3 | 0.1-0.4 | N/A | 22-24 | 1.8-2.5 | 15-16 | N/A | N/A | ≤0.50 |

Specific Applications

In the field of energy, ERNiCrMo-13 nickel based welding wire is mainly used in the following areas:

Advantages and Characteristics

|