| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Powder Feeder Machine |

|---|---|

| Brand Name: | Walthmac |

| Model Number: | WPB-T50 |

| Certification: | ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | $11,000.00-$12,500.00 |

| Payment Terms: | T/T, L/C, D/P, Western Union |

| Supply Ability: | 80 sets per month |

| Delivery Time: | 5-8 working weeks |

| Packaging Details: | Wooden cases |

| Condition: | New |

| Waranty: | 1 year |

| Machinery Test: | Provided |

| Control Units: | Adaption Algorithm |

| Output: | 1.8-532 dm3/h |

| Size: | 750*580*1230 |

| Operation voltage: | AC 220V |

| Mechanism materials: | Stainless steel,aluminum alloy |

| Company Info. |

| WalthMac Measurement&Control Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Multi Powder Materials Feeding Systems For Additive Manufacturing

1.Introduction

Powder Materials Feeding System widely used in engineering

plastics,chemicals,cables,medicine fields etc.Especially for

materials like viscous additives.It could work independently or

co-work with other devices and customers can choose different types

of screws according to the shape of materials.

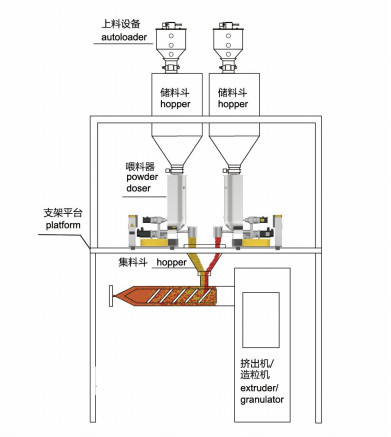

2.System Principle

3.Parameter

| The Application for Material | Powdery,Granular,Flake |

| Component | 1 component |

| Machanism Material | Stainless steel,Aluminum alloy |

| Feeding/dosing error | <0.3-0.5% |

| Power | 200-1800W |

4.Features

5.Advantages

6.Used area

Generally Speaking the manufactures such as using masterbatch,

additive,powder or other auxiliary materials in the process of

producing will get much assistance by Powder Materials Feeding

System.

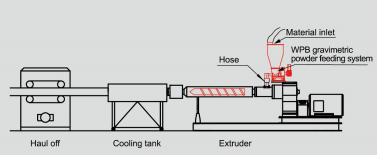

7.The installation

Installing the Powder Materials Feeding System with the platform on

the extruder,the materials will release from the hose.

8.On-sight Application

9.Profile of WalthMac

Mianyang WalthMac Technology Co., Ltd. is a national high-tech

enterprise pursuing "product is art". We have set high standards

for product design, internal management, and quality control.

Achieving a highly intelligent workshop in the future is the trend

of factories in the future, and it is also the parent goal for

Worth to strive for. Worth products focus on helping users achieve

automation throughout the production process, from improving

product quality and saving raw materials to reducing the dependence

on labor throughout the process.

Since extablished in 2009,in these 14 years, we have participated

in plastic and rubber exhibitions in China and other countries such

as Vietnam,Thailand,America,England etc. We are cooperating with

over 800 companies like DEMUKA,GSM etc, and establishing long-term

cooperative relationships with them.

|