| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roof Ridge Cap Roll Forming Machine |

|---|---|

| Brand Name: | JCX |

| Model Number: | roof ridge cover cap roll forming machine |

| Certification: | CE ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD8000-USD12500 PER SET |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 30 SETS PER MONTH |

| Delivery Time: | 20-30 working days |

| Packaging Details: | Sea worthy standard package: covered with plastic film, fixed into 20/40'gp container |

| Product name: | Roof Ridge Cap Roll Forming Machine |

| After-sales service provided: | Engineers available to service machinery overseas |

| Voltage: | 380V 50Hz 3phases |

| Condition: | New |

| Warranty: | 12 Months,and life long tracking service |

| Control system: | PLC control system(brand as requirement) |

| Weight: | 3.5T |

| Length and piece measure: | Omron Encoder |

| Need container: | 1*20 Feet |

| Export port: | Tianjin Port |

| Company Info. |

| Botou Golden Integrity Roll Forming Machine Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Good quality metal material roof sheet ridge tile cover roll forming machine with factory price

1. Description of roof ridge cover cap roll forming machine:

we are the professional Ridge cap roll forming machine manufacturer in China, and we export Ridge cap roll forming machine all over the world like India, Thailand, Russia, Algeria, Qatar, Morocco, Saudi Arabic, Oman etc. Ridge cap roll forming machine popular sell in many countries, we make cap ridge machine as customer' drawing. Material common is PPGI material, material thickness common between 0.3-0.8 mm.

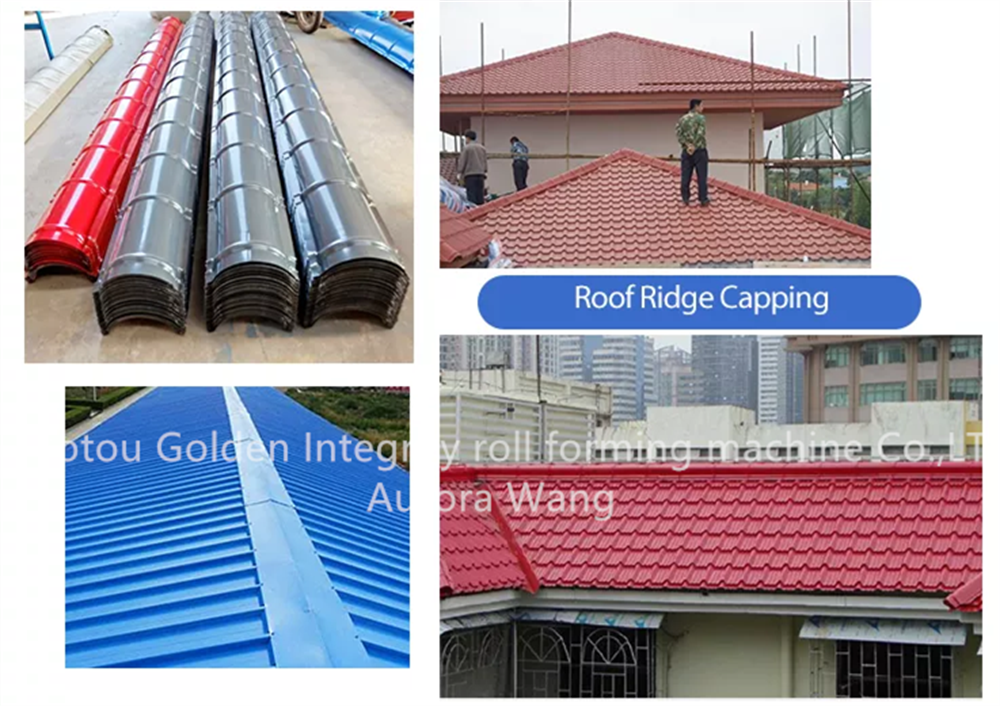

The ridge cap is used to seal the point at which two upward slopes meet. This can be both along the ridge of the roof as well as a covering for a hip. Either wood grip or self-drilling cap TEK screws can be used, and are applied through the ribs of the metal.

2. Technical details of door shutter roll forming machine:

3. Main components of door shutter roll forming machine

| No. | Each Part Of The Line | Quantity | Function And Usage |

| 1. | 3 Ton Uncoiler / Decoiler | 1 set | Hold the steel coils and unwind the coils |

| 2. | Ridge Cap Cold Roll Former | 1 set | Roll form the material into required profile |

| 3. | Punching and Cutting Device | 1 set | Punch ribs on formed ridge cap and cut to desired length |

| 4. | Run Out Table | 2 sets | Support ridge cap when it exits the machine |

| 5. | Electric Control Cabinet | 1 set | Highly automatic with PLC control system |

| 6. | Hydraulic Station | 1 set | Hydraulically powered for punching and cutting |

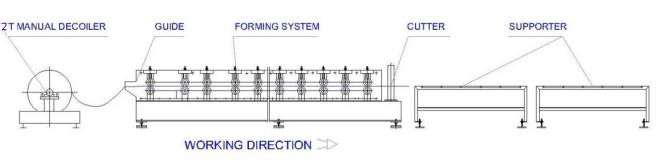

4. Production Flows

Uncoiling the sheet---Infeed guiding--Roll forming---Rectifying the straightness---Measure length---Cutting the panel--panels to the supporter (option: automatic stacker)

5. Advantages

· Germany COPRA software design

· 5 engineers with more than 20 years experience

· 30 professional technician

· 20 sets advanced CNC production lines on site

· Passionate Team

· Installation engineers can reach your factory within 6 days

· 1.5 years maintenance and whole life technical support

6. Application

This machine is widely used in the production of the ridge caps

7. Product photo

8. FAQ

1. who are we?

We are based in Hebie, China, start from 2010,sell to

Africa(20.00%),Domestic Market(20.00%),Southeast Asia(15.00%),South

America(10.00%),North America(5.00%),Eastern

Europe(5.00%),Oceania(5.00%),Mid East(5.00%),Central

America(5.00%),South Asia(5.00%),Eastern Asia(2.00%),Western

Europe(2.00%),Southern Europe(00.00%). There are total about 51-100

people in our office.

2. how can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.what can you buy from us?

Roof Sheet Roll Forming Machine,Wall Panel Roll Forming

Machine,Highway Guardrail Plate Forming Machine,Floor Decking Sheet

Rolling Machine,C Purlin Making Machine

4. why should you buy from us not from other suppliers?

1.Rich experience 2.High-quality after-sales service system 3.Brand

and Qualification Guarantee 4.Technological innovation advantage

5. what services can we provide?

Accepted Delivery Terms:

FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express

Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit

Card,PayPal,Western Union,Cash,Escrow;

Language

Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian

|