| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Bushing Sleeve |

|---|---|

| Place of Origin: | China |

| MOQ: | 35,00,0pcs |

| Price: | USD |

| Payment Terms: | T/T |

| Supply Ability: | 400,00,00pcs per month |

| Delivery Time: | 45days |

| Packaging Details: | Bubble bag and carton |

| Material: | Copper alloy |

| Application: | Universal |

| Weight: | 30g |

| Thickness: | 30.35(mm) |

| OD: | 30.40(mm) |

| Certificate: | ISO9001 |

| Service: | Customized OEM/ODM |

| Company Info. |

| Jiaxing Dexun Co.,Ltd. |

| View Contact Details |

| Product List |

Sliding Copper high-strength bushing sleeve thin-walled 35*40*35 25*30*30.

Description

The bushing is a matching part used outside the mechanical parts to achieve the functions of sealing, wear protection, etc. It refers to the ring sleeve that functions as a gasket. In the field of valve applications, the bushing is inside the valve cover, and corrosion-resistant materials such as polytetrafluoroethylene or graphite are generally used for sealing.

Bushings are used in: packaging machinery, textile machinery, mining machinery, metallurgical machinery, printing machinery, tobacco machinery, forging machinery, various types of machine tools and interchangeable mechanical transmission connections.

Copper-based alloys with a certain amount of other elements added. Copper alloy has medium strength, easy processing, relatively fatigue resistance, beautiful color, and good electrical conductivity, thermal conductivity and corrosion resistance. It is an important branch of heavy non-ferrous metal materials.

Copper alloys are better electrical conductors. The conductivity of

pure copper is between 100% and 103% IACS (see copper for the

definition of IACS). The addition of any solid solution alloying

element will reduce the electrical conductivity of copper, and the

reduction in unit atomic concentration mainly depends on the effect

of alloying elements on the copper lattice, and increases with the

increase of the addition amount in the solid solution range.

Strength Copper alloy has medium strength, and the tensile strength

of industrial pure copper in annealed state is about 240MPa. The

strength of copper alloys can be improved by means of solid

solution strengthening, work hardening, precipitation hardening

(including metastable decomposition), grain refinement and

dispersion strengthening. Cold working can be used alone to harden

alloys or in combination with precipitation hardening or metastable

decomposition to achieve strengthening.

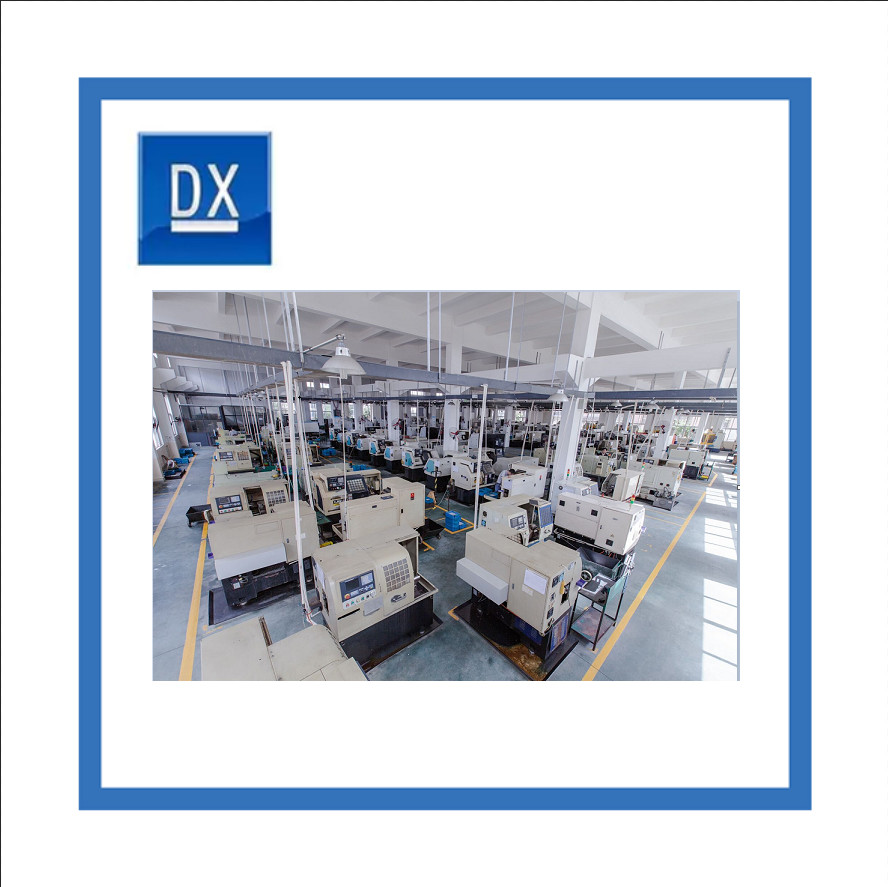

| CNC Machining | Description |

| Product name | Sliding Copper high-strength bushing sleeve thin-walled 35*40*35 25*30*30 |

| Material | Copper alloy |

| Weight | 30g |

| Surface Feature | Smooth surface;No burrs |

| Brand | Can be customized |

| ID | 30.35(mm) |

| OD | 30.40(mm) |

| Weight | 30(g) |

| Certificate | ISO9001 |

| Service | Customized OEM/ODM |

Factory Display

Packing way

Package

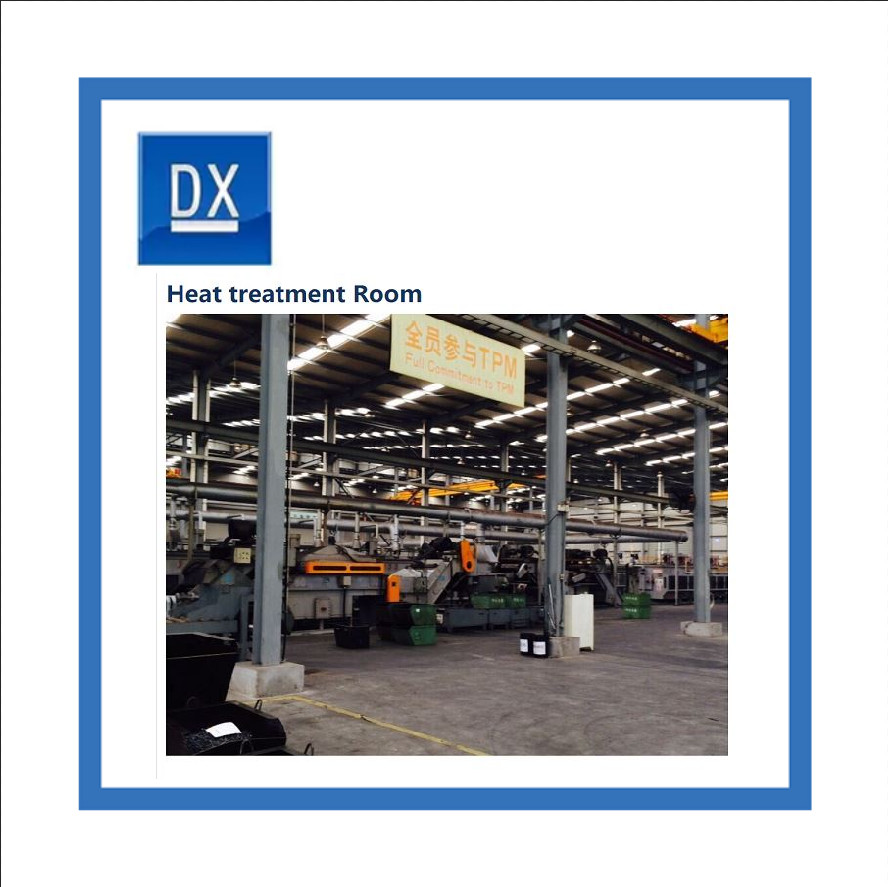

Heat Treatment

1.Q:What information does the quotation need?

A:Pls. offer your drawings and/or samples, quantity and packing’s

requirements.

Drawings in PDF, IGS, DWG, STEP, MAX are suitable to us.

2.Q:What’s lead time for samples and products?

A:Lead time for samples: 30-70days depend on the structure of the

part and other requirements on heat treatment, machining, surface

treatment and so on.

Mass production lead time: 35-70days depend on products’

characteristics and quantity.

3.Q:What is the requirement on payment?

Tooling Cost:50% deposit,50% after samples passed.

Payment for the Order:50% deposit,50% to be paid before shipment.

|