| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Bushing Sleeve |

|---|---|

| Place of Origin: | China |

| MOQ: | 35,00,0pcs |

| Price: | USD |

| Payment Terms: | T/T |

| Supply Ability: | 400,00,00pcs per month |

| Delivery Time: | 45days |

| Packaging Details: | Poly bag+Carton with pallet |

| Material: | Alloy Steel |

| Surface: | Per customer's requirement |

| Coating: | Dacromet |

| Color: | Matte silver |

| ID: | Customization |

| Certificate: | ISO9001:2008 |

| Service: | Customized OEM/ODM |

| Application: | Industry |

| Diameter: | 1000-7000mm |

| Height: | 120-2000mm |

| Company Info. |

| Jiaxing Dexun Co.,Ltd. |

| View Contact Details |

| Product List |

Alloy steel rotary kiln tyre bushing sleeve with Dacromet coating for industry.

Description

The bushing is a matching part used outside the mechanical parts to achieve the functions of sealing, wear protection, etc. It refers to the ring sleeve that functions as a gasket. In the field of valve applications, the bushing is inside the valve cover, and corrosion-resistant materials such as polytetrafluoroethylene or graphite are generally used for sealing.

Dacromet is a new type of anticorrosive coating with zinc powder, aluminum powder, chromic acid and deionized water as the main components.

The protective effect of Dacromet film on the steel substrate can

be summarized as follows:

1. Barrier effect: due to the layered overlap of flake zinc and

aluminum, it prevents the process of corrosive media such as water

and oxygen from reaching the substrate, which can act as an

isolation shield.

2. Passivation: In the process of Dacromet, chromic acid reacts

with zinc, aluminum powder and base metal to form a dense

passivation film, which has good corrosion resistance.

3. Cathodic protection: The main protective effect of the

zinc-aluminum-chromium coating is the same as that of the

galvanized layer, which is the cathodic protection of the

substrate.

Dacromet has the following advantages

1. Super corrosion resistance: The thickness of Dacromet film is

only 4-8μm, but its anti-rust effect is more than 7-10 times that

of traditional electro-galvanizing, hot-dip galvanizing or paint

coating. The standard parts and pipe joints treated with Dacromet

process did not show red rust after the salt spray resistance test

for more than 1200 hours.

2. No hydrogen embrittlement: Dacromet's processing technology

determines that Dacromet has no hydrogen embrittlement phenomenon,

so Dacromet is very suitable for the coating of stressed parts.

3. High heat resistance: Dacromet can withstand high temperature

corrosion, and the heat resistance temperature can reach above

300℃.

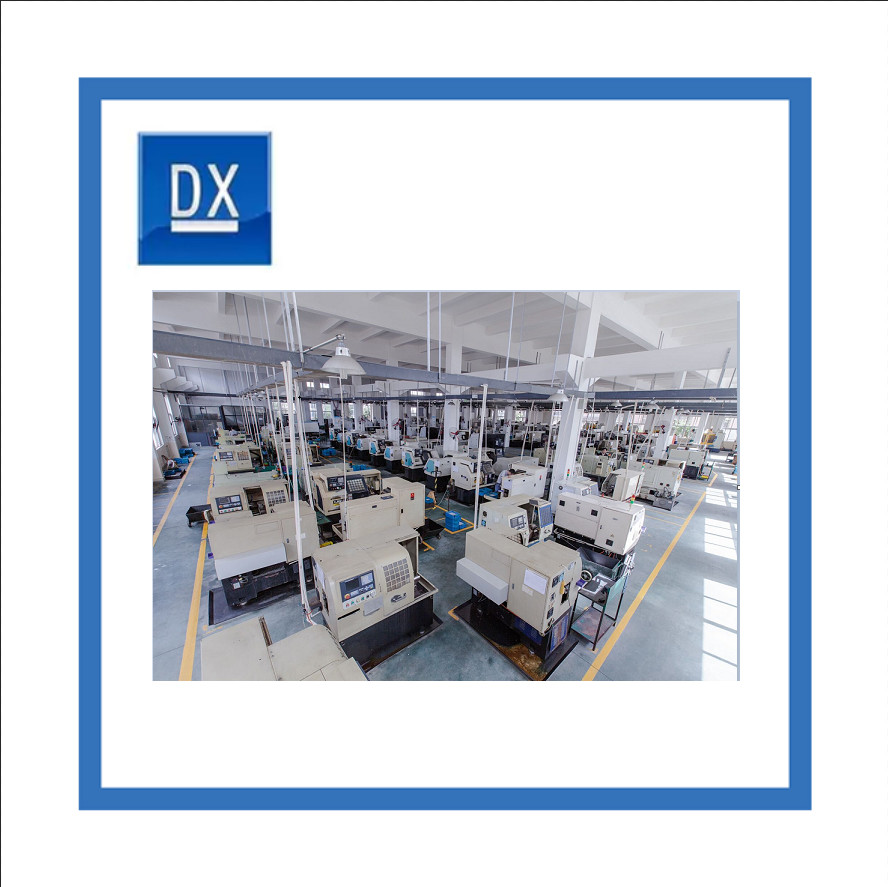

| CNC Machining | Description |

| Product name | Alloy steel rotary kiln tyre bushing sleeve with Dacromet coating for industry |

| Material | Alloy steel |

| Color | Matte silver |

| Coating | Dacromet |

| Diameter | 1000-7000mm |

| Height | 120-2000mm |

| Drawing Format | DWG/DXF/IGS/STEP/X-T and PDF |

| Certificate | ISO9001 |

| Service | OEM/ODM |

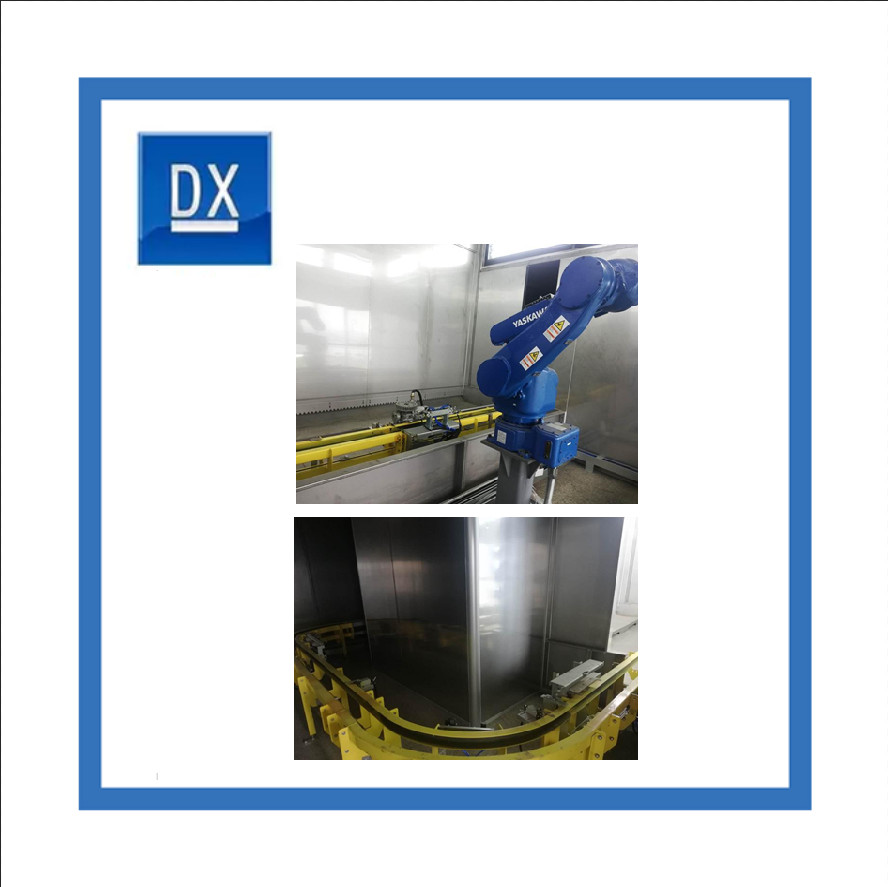

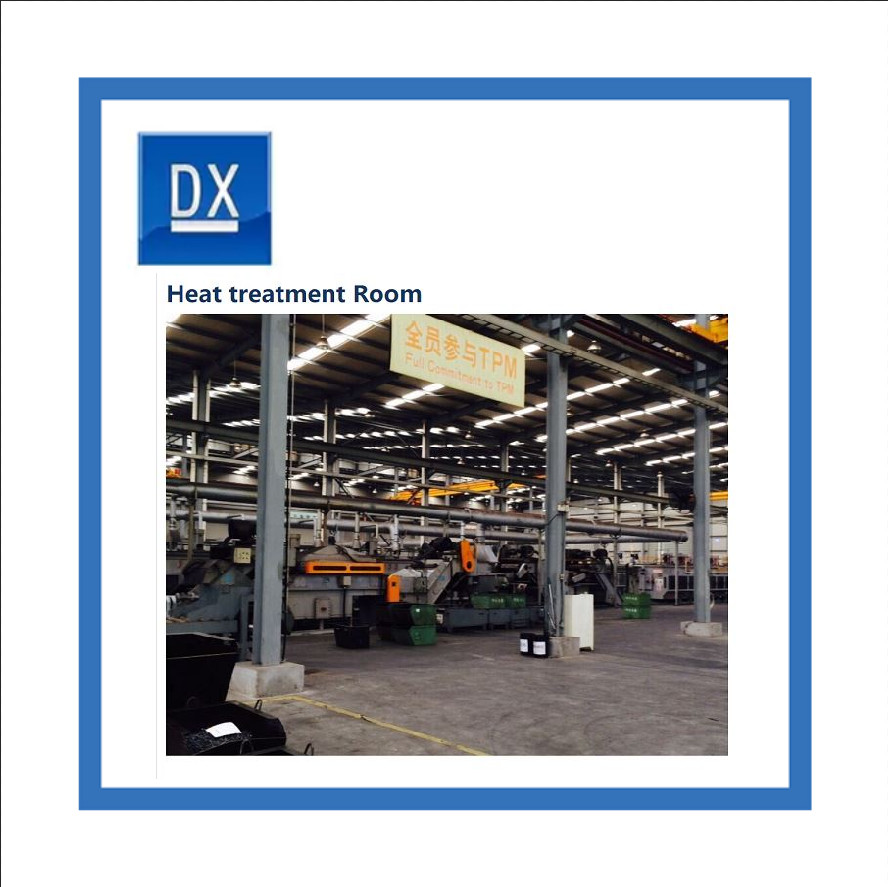

Factory Display

Packing way

Package

Plating line

Heat Treatment

1Q:What information does the quotation need?

A:Pls. offer your drawings and/or samples, quantity and packing’s

requirements.

Drawings in PDF, IGS, DWG, STEP, MAX are suitable to us.

2Q:What’s lead time for samples and products?

A:Lead time for samples: 30-70days depend on the structure of the

part and other requirements on heat treatment, machining, surface

treatment and so on.

Mass production lead time: 35-70days depend on products’

characteristics and quantity.

3Q:What is the requirement on payment?

Tooling Cost:50% deposit,50% after samples passed.

Payment for the Order:50% deposit,50% to be paid before shipment.

|