| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Bushing Sleeve |

|---|---|

| Place of Origin: | China |

| MOQ: | 35,00,0pcs |

| Price: | USD |

| Payment Terms: | T/T |

| Supply Ability: | 400,00,00pcs per month |

| Delivery Time: | 45days |

| Packaging Details: | Poly bag+Carton with pallet |

| Material: | 20Cr |

| SurfaceTreatment: | Annealing |

| Coating: | Geomet |

| Heat Treatment: | Carburizing heat treatment |

| Hardness: | HRC60±2 |

| ID: | Customization |

| Certificate: | ISO9001:2008 |

| Service: | Customized OEM/ODM |

| Application: | Molding Ejection Equipment |

| Samples: | Avaliable |

| Company Info. |

| Jiaxing Dexun Co.,Ltd. |

| View Contact Details |

| Product List |

20Cr Geomet Coating carburizing heat treatment bushing for Molding Ejection.

Description

The bushing is a matching part used outside the mechanical parts to achieve the functions of sealing, wear protection, etc. It refers to the ring sleeve that functions as a gasket. In the field of valve applications, the bushing is inside the valve cover, and corrosion-resistant materials such as polytetrafluoroethylene or graphite are generally used for sealing.

Geomet is more environmentally friendly and has stronger salt spray performance.

The appearance of Jiao Mei Te coating is matt silver gray, and its gloss is slightly darker than Dacromet coating. It is an inorganic coating that combines ultra-fine zinc flakes and aluminum flakes in a special binder.

Advantages:

(1) Barrier protection: The treated layered zinc flakes and aluminum flakes provide an excellent barrier between the steel substrate and the corrosive medium, preventing the corrosive medium and depolarizer from reaching the substrate.

(2) Electrochemical effect: The zinc layer is corroded as a sacrificial anode to protect the steel substrate.

(3) Passivation: The metal oxide produced by passivation slows down the corrosion reaction speed of zinc and steel.

(4) Self-repairing effect: When the coating is damaged, zinc oxide and carbonate move to the damaged area of the coating, actively repairing the coating and restoring the protective barrier.

| CNC Machining | Description |

| Product name | 20Cr Geomet Coating carburizing heat treatment bushing for Molding Ejection |

| Material | 20Cr |

| Surface Roughness | Ra1.6 |

| Coating | Geomet |

| Heat Treatment | Carburizing heat treatment |

| Hardness | HRC60±2 |

| Drawing Format | DWG/DXF/IGS/STEP/X-T and PDF |

| Certificate | ISO9001 |

| Service | OEM/ODM |

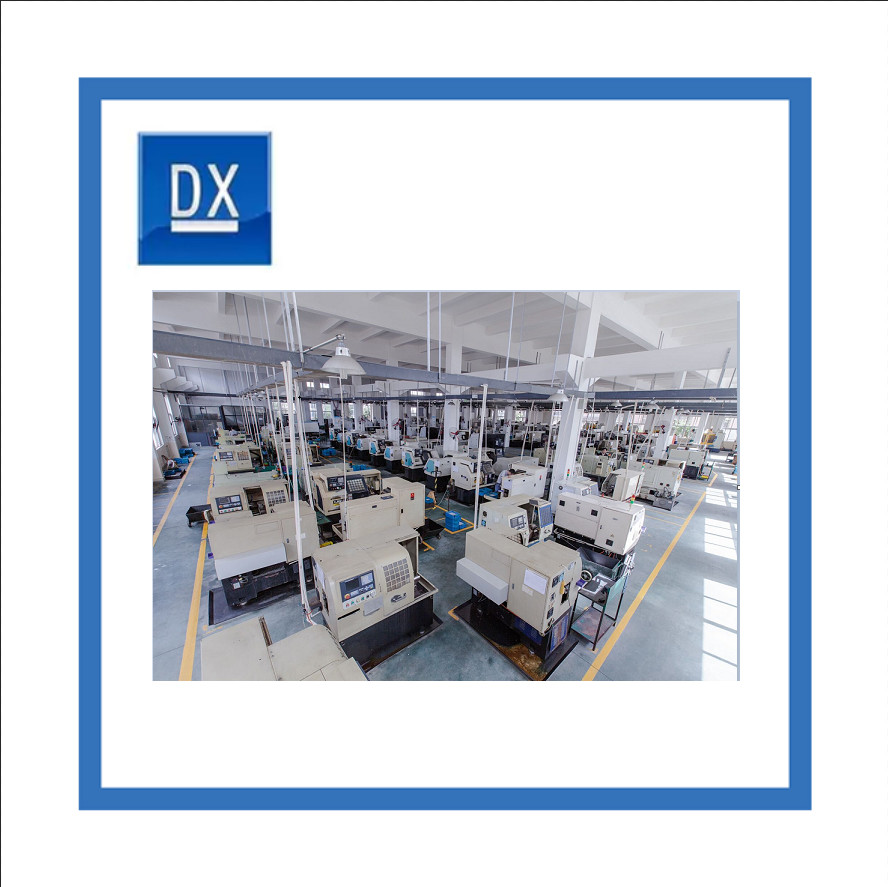

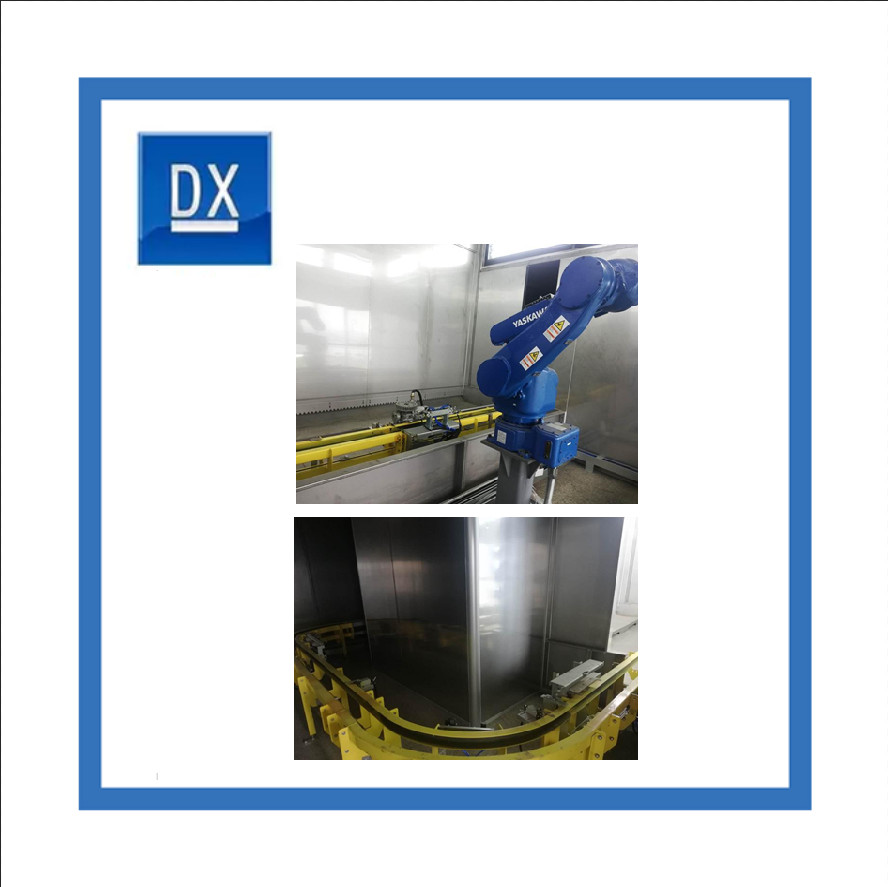

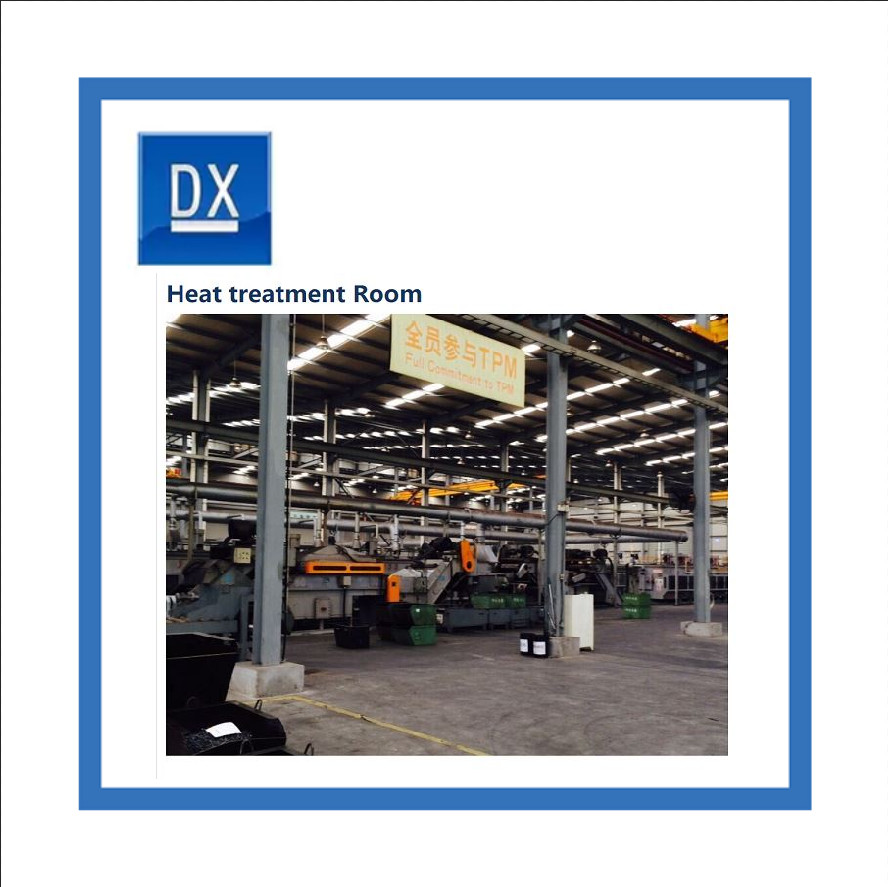

Factory Display

Packing way

Package

Plating line

Heat Treatment

1Q:What information does the quotation need?

A:Pls. offer your drawings and/or samples, quantity and packing’s

requirements.

Drawings in PDF, IGS, DWG, STEP, MAX are suitable to us.

2Q:What’s lead time for samples and products?

A:Lead time for samples: 30-70days depend on the structure of the

part and other requirements on heat treatment, machining, surface

treatment and so on.

Mass production lead time: 35-70days depend on products’

characteristics and quantity.

3Q:What is the requirement on payment?

Tooling Cost:50% deposit,50% after samples passed.

Payment for the Order:50% deposit,50% to be paid before shipment.

|