| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Metal Bearing Balls |

|---|---|

| Brand Name: | OEM , ODM |

| Model Number: | 34.30mm(1.350394") |

| Certification: | SGS,ISO9001,IAF,CNAS |

| Place of Origin: | china |

| MOQ: | 4590pcs |

| Price: | FOB tianjin port, qingdao port |

| Payment Terms: | L/C, T/T |

| Delivery Time: | 20-30days |

| Packaging Details: | Plastic bag+ cardon box+ wooden pallet |

| material: | chrome steel,high carbon steel, GCr15, SUJ2 |

| Grade: | G28 |

| Hardness: | HRc61 to HRc67 |

| surface: | lapping, Bright, high polished |

| usage: | Ball Bearing, mechanical equipment |

| Standard: | DIN, ASTM, AISI, JIS, AFN |

| feature: | smooth, anti-wear, corrosion Resistance |

| free Sample: | provide for free |

| Company Info. |

| Xi'an machinery & engineering import & export co.,ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

34.30mm(1.350394"), 34.10mm,34.2mm,34.4mm to 35.1mm, High Chrome Steel Ball For

Bearing

Introduction

GCr15 bearing steel is a kind of high-carbon chromium bearing steel

with low alloy content, good performance and the most useful. It

has high hardness, uniform good structural properties, good wear resistance and high contact fatigue performance after

quenching and tempering. The steel has the characteristics of

moderate plasticity, low cutting performance, poor welding

performance, high sensitivity to white spots and temper

brittleness. GCr15 bearing steel, containing C0.95-1.05,

Mn0.25-0.45, Si0.15-0.35, Cr 1.40-1.65.

GCr15SiMn steel is a high-carbon, high-chromium bearing steel, which has higher wear resistance and hardenability than GCr15 steel. The critical quenching diameter in oil is 90~110mm (volume fraction of 50% martensite). After oil quenching at 840°C, tempering at 350°C, and then light quenching, the surface hardness is as high as 1096HV, and the depth of the hardened layer can reach 1mm. In view of the insufficiency of the heat treatment process of the forming roller, the non-martensitic transformation occurs by pre-cooling at the thin edge to produce troostite or sorbite, which enhances toughness, reduces stress, and then quenches as a whole to meet the process requirements.

The ice-cold treatment can improve the dimensional stability of the bearing, or perform martensite graded quenching to stabilize retained austenite and obtain high dimensional stability and higher toughness. This steel is generally not recommended for forging. Generally used after quenching and low temperature tempering.

High Precision bearing (chrome) steel ball

| Grade | Hardness | Material | Ball Diameter |

| G20 | HRc 62-67 | Gcr15(52100,100Cr6,SUJ2) | 5/8" (15.875mm) -- 1" (25.4mm) |

| G28 | HRc 61-67 | Gcr15(52100,100Cr6,SUJ2) | 1 1/8"(28.575mm) -- 1 3/8" (34.925mm) |

| G40 | HRc 61-67 | Gcr15(52100,100Cr6,SUJ2) | 1 1/2" (38.1mm) -- 2 1/6" 55mm |

| G40 | HRc 61-67 | Gcr15(52100,100Cr6,SUJ2) | (44.94mm - 45.06mm) |

| G40 | HRc 61-67 | Gcr15(52100,100Cr6,SUJ2) | (49.94mm - 50.06mm) |

| G40 | HRc 61-67 | GCr15SiMn,100CrSiMn6-4,SUJ3,52100 | (59.94mm- 60.06mm) |

| G40 or G60 | HRc 61-67 | GCr15SiMn,100CrSiMn6-4,SUJ3,52100 | (62.94mm - 63.06mm) |

| G60 or G100 | HRc 57-63 | GCr15SiMn,100CrSiMn6-4,SUJ3,52100 | 3" (76.2mm) |

| G100 | HRc 59-65 | GCr15SiMn,100CrSiMn6-4,SUJ3,52100 | 2 3/4" (69.85mm) -- 3 3/20" (80mm) |

| G100 | HRc 57-63 | GCr15SiMn,100CrSiMn6-4,SUJ3,52100 | 3 1/4" ( 82.55mm) |

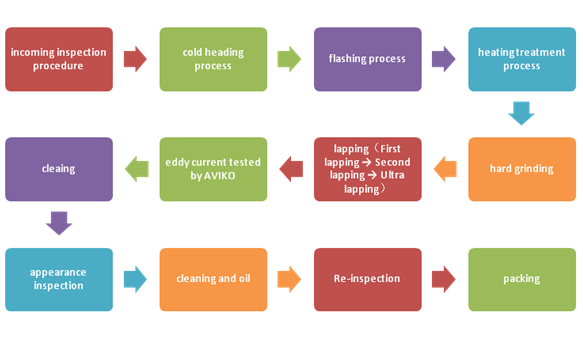

Chrome steel and other metal balls are manufactured using the following processe

|