| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cold Roll Forming Machine |

|---|---|

| Brand Name: | Co-effort |

| Model Number: | GD170 |

| Certification: | CO,CE,FORM A, FORM E,ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 40000/set |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets for 75 working days, usually have stock |

| Delivery Time: | 75 working days |

| Packaging Details: | Plastic Film and Wooden Case |

| Machine Name: | 700mm Diameter Band Clamp Omega Cold Roll Forming Machine |

| Usage: | Omega V Band Clamp |

| Diameter: | 55~800mm |

| Thickness of Coil: | 0.8mm to 3mm |

| Width of Coil: | 30mm ~ 120mm |

| Material of Rollers: | Cr12Mov |

| Stations: | 8 Stations |

| Motor: | Servo Motor 11KW |

| Color: | Blackening |

| Bearing Brand: | NSK |

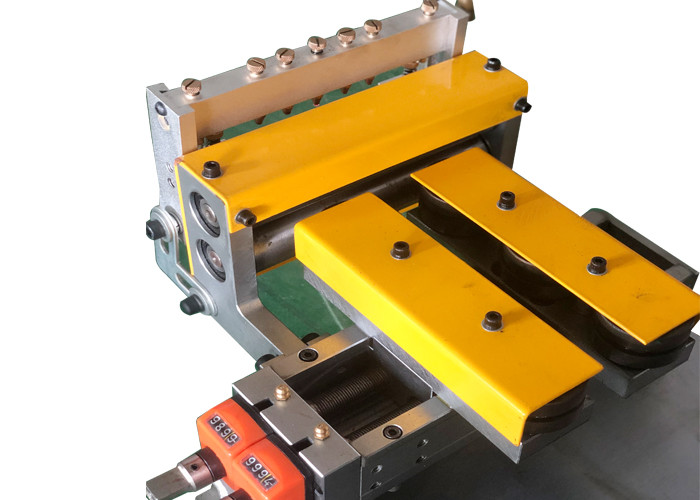

700mm Diameter Band Clamp Omega Cold Roll Forming Machine

Our Omega V Clamp Cold Roll Forming Machine Advantages

1. High Precision, High Speed, High Capacity and Stable Performance

2. Just need one time to formed instead of use punching machines, shear machines and other machines

3. Save time, save cost

4. Improve production efficiency and clamping rings quality

5. The pass stations are easy to disassemble, install and maintain

6. The lubrication system for segment forming will be self-contained within the machine. The excess lubrication from the forming process will be re-circulated, filtered and re-used.

Product Application

This kind of roll forming machine uses stainless steel as raw

material, through decoiler, straightening, roll forming and cutter

processes, it can produce all kinds of clamping rings.

Machine Parameters

| No | Items | Technical Requirements |

| 1 | Production Process | De-coiler --- Leveling --- Roll Forming --- Rolling Head --- Cut off |

| 2 | Floor Area | 15×2.5×2(L×W×H)M |

| 3 | Feeding Direction | From Left to Right |

| 4 | Voltage | 380V,50Hz,3 Phase |

| 5 | Air Supply | Flow Rate:0.5m³/min; Pressure: 0-0.7MPa |

| 6 | Hydraulic Fluid | 46# |

| 7 | Gear Oil | 150# |

| 8 | Material of Strip | Stainless Steel |

| 9 | Width of Strip | ≤80mm |

| 10 | Thickness of Strip | ≤2.8mm |

| 11 | Speed | 10 components per minute for diameter 378mm 15 components per minute for diameter 248mm 20 to 25 components per minute for diameter 115.8 to 127.4mm 20 to 25 components per minute for diameter 127.4 to 155.8mm 20 to 35 components per minute for diameter 72.6 to 148.8mm |

| 12 | Length Tolerance | ±0.25mm |

| 13 | Total Power | Around 25 KW |

Main Devices of Roll Forming Machines

| No | Items | Model | Qty | Remark |

| 1 | De-coiler and Straightening Combine Device | LS-300F | 1 set | |

| 2 | Roll Forming Device | 1 set | ||

| 3 | Guarding Cover | 1 set | ||

| 4 | Control System | 1 set |

Electric Elements Brand

| No | Items | Brand | Remark |

| 1 | PLC | OMRON | |

| 2 | HMI | WEINVIEW | |

| 3 | Electric Elements | Schneider | |

| 4 | Bearing | NSK | |

| 5 | Main Motor | YASKAWA Servo Motor | |

| 6 | Digital Position Display | SIKO |

Technical Configuration

No | Items | Technical Parameters | |

1 | De-coiler and Straightening Combine Device | Width of Strip | 30-100mm; |

Thickness of Strip | ≤3.5mm; | ||

Inner Diameter of Coil | ф480-520 mm(according to customer’s requirements); | ||

Outer Diameter of Coil | φ1300mm;Loading Weight:≤2T | ||

Expand Way | Manual | ||

Power | De-coiler no power | ||

Width of Strip | 30-100mm; | ||

Thickness of Strip | ≤2mm; | ||

Motor Power | 3 KW (straightening power) | ||

Speed | Max16m/min | ||

Roller Arrangement | 7 rollers | ||

Arrange mode | 4-Point Independent | ||

2 | Roll Forming and Cutting Device | Forming Stations | 8 Stations |

Type of Driven | Gear | ||

Forming Rack: | High strength guide pillar gantry horizontal frame. The slider rollers are adjusted by digital display. | ||

Station Pitch | 250mm | ||

Max. Feeding Width of Coil | 100mm | ||

Max. Thickness of Material | 3.5mm | ||

Diameter of Shafts | Φ60mm ,42CrMo (quenching and tempering) | ||

Material of Roller | Cr12,Hardness: HRC58-60° | ||

Main Driven Motor | 37KW (Servo Motor) | ||

Bending and Cutting Devices | 1 set | ||

Lubrication system

The lubrication system for segment forming will be self-contained within the machine. The excess lubrication from the forming process will be re-circulated, filtered and re-used.

Rolling Head of Omega and V Band Clamps

FAQ for Band Clamp Roll Forming Machine

Q: How many people are needed to operate the clamp roll forming machine?

A: Our clamp rolling machine is fully automatic, one person can operate many sets.

Q: What is the safety performance of the machine?

A: First of all, there is a sensor in the guiding part of the machine. When there is no material, the machine will stop automatically. Secondly, our machine can make protective devices according to the requirements of customers. When any door is opened, the machine can also stop automatically.

Q: What's the min. diameter and max. diameter of clamps your machine can do?

A: 55~800mm

|