| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cold Roll Forming Machine |

|---|---|

| Brand Name: | Co-effort |

| Model Number: | GD140 |

| Certification: | CO,CE,FORM A, FORM E |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 40000/set |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets for 75 working days, usually have stock |

| Delivery Time: | 75 working days |

| Packaging Details: | Plastic Film and Wooden Case |

| Usage: | V-Band Clamping Rings |

| Name: | Roll Forming Machine |

| Speed: | 30 components for one minute |

| Material: | Blank or Spray-paint |

| Hoop Barrel Clamp Ring Material: | Stainless Steel |

| Thickness of Coil: | 0.8mm to 3mm |

| Width of Coil: | 30mm ~ 120mm |

| Material of Rollers: | Cr12Mov |

| Stations: | 6 to 12 Stations |

Stainless Steel G Coupling Clamp Cold Roll Forming Machine

Our Clamping Rings Roll Forming Machine Advantages

1. High Speed and Stable Performance

2. Just need one time to formed instead of use punching machines, shear machines and other machines

3. Save time, save cost

4. Improve production efficiency and clamping rings quality

Product Application

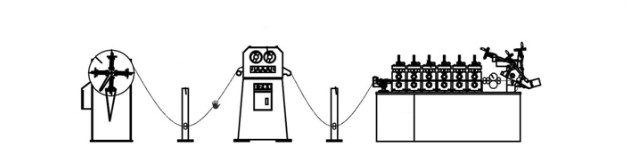

This kind of roll forming machine uses stainless steel as raw

material, through decoiler, straightening, roll forming and cutter

processes, it can produce all kinds of clamping rings.

Frequency converter controls motor speed, PLC system automatically

controls length and quantity, realizes continuous automatic

production, and is an ideal equipment in cold roll forming

industry.

Main Devices of Roll Forming Machines

| No | Items | Model | Qty | Remark |

| 1 | De-coiler and Straightening Combine Device | LS-300F | 1 set | |

| 2 | Roll Forming Device | 1 set | ||

| 3 | Guarding Cover | 1 set | ||

| 4 | Control System | 1 set |

Electric Elements Brand

| No | Items | Brand | Remark |

| 1 | PLC | OMRON | |

| 2 | HMI | WEINVIEW | |

| 3 | Electric Elements | Schneider | |

| 4 | Bearing | NSK | |

| 5 | Main Motor | YASKAWA Servo Motor | |

| 6 | Digital Position Display | SIKO |

Technical Configuration

No | Items | Technical Parameters | |

1 | De-coiler and Straightening Combine Device | Width of Strip | 30-100mm; |

Thickness of Strip | ≤3.5mm; | ||

Inner Diameter of Coil | ф480-520 mm(according to customer’s requirements); | ||

Outer Diameter of Coil | φ1300mm;Loading Weight:≤2T | ||

Expand Way | Manual | ||

Power | De-coiler no power | ||

Width of Strip | 30-100mm; | ||

Thickness of Strip | ≤2mm; | ||

Motor Power | 3 KW (straightening power) | ||

Speed | Max16m/min | ||

Roller Arrangement | 7 rollers | ||

Arrange mode | 4-Point Independent | ||

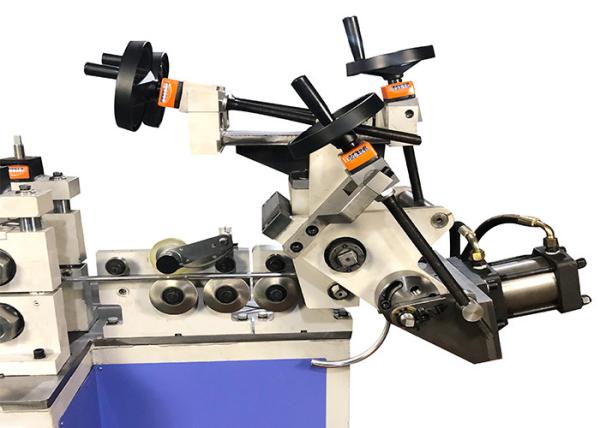

2 | Roll Forming and Cutting Device | Forming Stations | 12 Stations |

Type of Driven | Gear | ||

Forming Rack: | High strength guide pillar gantry horizontal frame. The slider rollers are adjusted by digital display. | ||

Station Pitch | 250mm | ||

Max. Feeding Width of Coil | 100mm | ||

Max. Thickness of Material | 3.5mm | ||

Diameter of Shafts | Φ60mm ,42CrMo (quenching and tempering) | ||

Material of Roller | Cr12,Hardness: HRC58-60° | ||

Main Driven Motor | 37KW (Servo Motor) | ||

Bending and Cutting Devices | 1 set | ||

|