| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Highway Guardrail Roll Forming Machine |

|---|---|

| Brand Name: | Co-effort |

| Model Number: | GD180 |

| Certification: | CO,CE,FORM A, FORM E |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 50000/set |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets for 75 working days |

| Delivery Time: | 75 working days |

| Packaging Details: | Plastic Film and Wooden Case |

| Name: | Highway Guardrail Roll Forming Machine |

| Coil Material: | Cold Rolled Steel |

| Thickness of Coil: | 2.0 to 4mm |

| Profile: | Two and Three Waves |

| Roll Forming Speed: | 10~20m/min |

| Contro: | PLC |

| Color: | As your requirement |

| Width of Coil: | 480mm |

Automatic Safety Road W Beam Steel Highway Guardrail Roll Forming Machine

Roll Forming Machine Introduce

This machine has the best quality and the best price. Accurate

measurement and convenient operation. We can design and manufacture

special types of machines according to customers' requirements. We

can provide technical guidance, production, installation,

commissioning and maintenance services for all customers.

The production line adopts galvanized steel plate, color steel

plate or aluminum plate as material plate. Its products are used as

roof tiles and wallboard outside the building, increasing the

beauty and durability of roof tiles and wallboard. This line has no

limit to the processing length. You can set up multiple different

data on the computer control cabinet according to your own needs.

After pressing the "confirm" button, the machine can automatically

generate the panel according to the set data. The surface of the

formwork is smooth, and it is not easy to mark when stamping. So

it's easy to install. The product conforms to the national steel

structure building standard.

Features of the production line

low cost

high efficiency

Reliable operation

Low energy consumption

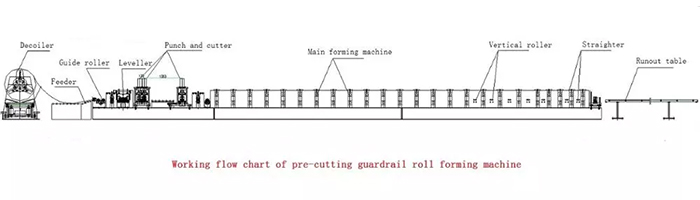

Technological process

Cut off the discharge of uncoiled charging die

Processing technology and deployment:

Uncoiler

Feeding platform

Mould core

Die cutting mechanism

Hydraulic station

This roll forming machine is designed for highway guardrail.

According to the requirements of customers, continuous forming and

automatic cutting. The equipment adopts PLC control and AC

frequency conversion technology to realize continuous automatic

production. It is a new type of energy-saving and efficient steel

roof or wall panel production equipment. The utility model has the

advantages of fast forming speed, low noise, stable transmission,

convenient operation, beautiful appearance, etc.

Description of Application Effects and Advantages

1. Coil Thickness: 2-4mm

2. Hydraulic power: 7.5Kw

3. Transmission way: gear box

4. Material of blad: Cr12, quenching treatment

5. Capacity of Decoiler: 5 Ton hydraulic decoiler

6. Forming Speed: 10-20m/min(not including punching time)

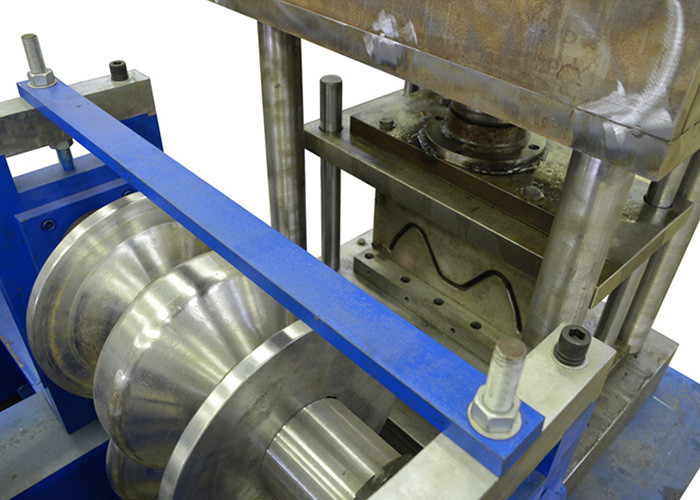

7. Roller Groups: 13 stations main roller

8. Roller Material: GCr15, quenching treatment

9. Roller Diameter: 180mm

10. Shaft: 45# high grade steel with quenching treatment

11. Main Motor Power: 55 Kw

Main configuration table

| No | Items | Qty | Remark |

| 1 | Decoiler | 1 set | |

| 2 | Leveling Machine | 1 set | |

| 3 | Hydraulic Punching Device | 1 set | |

| 4 | Roll Forming Device | 1 set | |

| 5 | Roller | 1 set | Quick Change |

| 6 | Cutting Device | 1 set | |

| 7 | Discharging rack | 1 set | |

| 8 | Automatic Stacker | 1 set | |

| 9 | Guarding System | 1 set | Optional |

| 10 | Control System | 1 set | |

| 11 | Voltage transformer | 1 set | According to customer’s request |

| 12 | Punching Device | 1 set | Optional |

Technical Parameter of Highway Guardrail Roll Forming Machine

| Main Motor Power | 7.5KW |

| Hydraulic Station Power | 4KW |

| Hydraulic Oil Pump | CB-E310 |

| Roller Material | 45# forged steel, hard chrome plating within 0.05mm |

| Diameter of shaft | 70mm |

| Main motor power | 37 KW |

| Drive type | Gear box or chain driven (according to customers) |

| Cutting Blade | Cr12 or Cr12Mov, heat treatment 60-62°C |

| Wave Height | 35mm ~ 125mm |

| Total Weight | 5.5T |

| Roller Station | 15 |

| Machine Size | 9*1.5*0.8M |

Electric Elements Brand

| No | Items | Brand |

| 1 | PLC | Delta |

| 2 | HMI | WEINVIEW |

| 3 | Electric Elements | Schneider or Delixi |

| 4 | Bearing | HRB, WZS or LYC |

| 5 | Main Motor | Wannan motor |

| 6 | Servo Motor | Delta |

Working Process of Highway Guardrail Roll Forming Machine

De-coiler → Leveling → Punching → Roll Forming → Cut Off → Output

|