| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Highway Guardrail Roll Forming Machine |

|---|---|

| Brand Name: | Co-effort |

| Model Number: | GD180 |

| Certification: | CO,CE,FORM A, FORM E |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD 50000/set |

| Payment Terms: | T/T |

| Supply Ability: | 10 sets for 75 working days |

| Delivery Time: | 75 working days |

| Packaging Details: | Plastic Film and Wooden Case |

| Profile: | Two and Three Waves or other steel profiles |

| Roll Forming Speed: | Max. 15m/min |

| Roller Material: | Cr12Mov |

| Cutting Blade Material: | Cr12 |

| Forming Stations: | 18 Stations |

| Driven Method: | Gearbox with shafts |

| Material: | Blank or Painted |

| Run-out Table: | Manual or Automatic |

| Main Power: | 95KW |

Fully Automatic Highway Guardrail Roll Forming Machine Metal Sheet Profile Making Line

Brief Introduction

The highway guardrail roll forming machine can form hot-rolled and cold-rolled steel strip as the protection side. We can provide various types according to customers' requirements for configuration, such as profile quantity, wall type, driving type.

Main Technical Configuration Parameters

Remark: below parameters are standard, we can design and make some change exactly according to your requirements.

| No | Items | Technical Parameters | |

| 1 | Decoiler | Width of Sheet metal | ≤500mm; |

| Thickness of Material | ≤3.5m; | ||

| Inner Diameter of Coil | ф480-520 mm(according to customer’s requirements) | ||

| Outer Diameter of Coil | φ1500mm;Loading Weight:≤5T | ||

| Form of pressing material | Pneumatic press arm | ||

| Brake | Air brake | ||

| Tightening Way | Hydraulic | ||

| Hydraulic Power | 3KW | ||

| 2 | Leveling Machine | Width of Sheet metal | ≤500mm; |

| Thickness of Material | ≤3.5m; | ||

| Leveling Rollers | 11 Rollers | ||

| Leveling Way | 5 rollers are upper, 6 rollers are lower | ||

| Power | Non-power | ||

| 3 | Hydraulic Punching Device | Thickness of Material | ≤3.5mm; |

| Number of stamping dies | 2 groups | ||

| Power way | Hydraulic | ||

| Adjustment way | Manual | ||

| Power of Hydraulic Station | 15KW | ||

| 4 | Roll Forming Device | Forming Station | 18 Stations |

| Driven | Gear Boxes | ||

| Gear Boxes | Gear material is 20CrMnTi. It is an arc bevel gear box, and the box body is high strength welded. | ||

| Forming Frames | Cast steel high strength gantry horizontal frame. The slider mould is adjusted by digital display. | ||

| Pitches of Passes | 650mm | ||

| Max. Width of Strip | 500mm | ||

| Max. Thickness of Strip | 3.5mm | ||

| Roller Shafts | Φ90mm, 42CrMo quenching and tempering treatment | ||

| Roller Material | Cr12, quenching treatment, Hardness is about HRC60° | ||

| Main Motor Power | 30KW*2 | ||

| Roller Cooling System | 1 set, combined spray and overflow pool | ||

| Turk Head | 2 set | ||

| 5 | Cutting Device | Cutting Way | Punching shear |

| Cutting Accuracy | Length Encoder Control Full Length±2MM | ||

| Power of Hydraulic Station | 11 KW | ||

| 6 | Discharging rack | Manual blanking structure | Roller type |

| Motor Power | 2.2KW | ||

| 7 | Automatic Stacker | Blanking structure | The automatic stacking adopts gantry frame structure. After the counter counts a certain number, the products are moved manually. |

| Trolley | Selection | ||

| No | Items | Technical Requirements |

| 1 | Equipment Floor Area | 24×2×2(L×W×H)M |

| 2 | Feeding Direction | From Right to Left |

| 3 | Voltage | 380V, 50Hz, 3 Phase |

| 1 | Material of Strip | Q235 |

| 2 | Width of Strip | ≤500mm |

| 3 | Thickness of Strip | ≤3.5mm |

| 4 | Length | ≤5m |

| 5 | Speed of Rolling | 5m~15m/min |

| 6 | Total capacity of equipment | Around 95KW |

Electric Elements Brand

| No | Items | Brand |

| 1 | PLC | Delta |

| 2 | HMI | WEINVIEW |

| 3 | Electric Elements | Schneider or Delixi |

| 4 | Bearing | HRB, WZS or LYC |

| 5 | Main Motor | Wannan motor |

| 6 | Servo Motor | Delta |

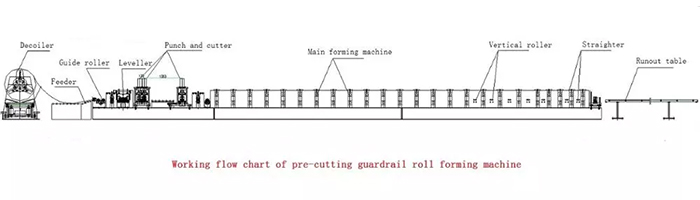

Working Process of Highway Guardrail Roll Forming Machine

De-coiler → Leveling → Punching → Roll Forming → Cut Off → Output

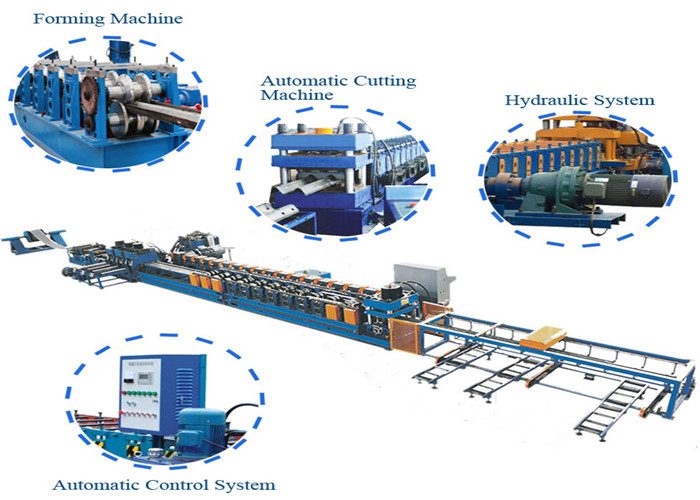

Two and Three Waves Fences Highway Road Roll Forming Machine Detailed Photos

|