| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Tile Roll Forming Machine |

|---|---|

| Brand Name: | Saibo |

| Model Number: | YX40-180-900 |

| Certification: | CE/ISO |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | negotiation |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 300 sets per year |

| Delivery Time: | 70 working days after received deposit |

| Packaging Details: | Suitable for ocean shipment |

| Product Name: | Tile Roll Forming Machine |

| Power: | 7.5KW+5.5kw |

| Decoiler: | Hydraulic |

| Station: | 19 stations |

| Steel thickness: | 0.4-0.6mm |

| Roller material: | ASTM1045 chrome plated surface with chrome |

| Drive: | By chain |

| Productivity: | 5-8m/min |

1. Specification of the material

| 1 | Suitable Material | Colored Steel plate, Galvanized steel |

| 2 | Width of the raw material | 1200mm |

| 3 | Thickness | 0.4-0.6mm |

2. Machine Detailed Parameters

| 1 | Roll Forming Machine | YX40-180-900 |

| 2 | Machine structure | Wall panel structure |

| 3 | Total power | Motor power-7.5kw servo motor Hydraulic power-5.5kw |

| 4 | Roller stations | About 19 stations |

| 5 | Productivity | 5-8m/min |

| 6 | Drive system | By chain, one complete chain |

| 7 | Diameter of shaft | ¢70mm solid shaft |

| 8 | Voltage | 380v 50Hz 3phase |

| 9 | Color Of The Machine | Yellow and blue |

| 10 | Container need | 40GP container |

| 11 | Deliver Time | 70 days |

| 12 | Terms Of Payment | 30%T/T 70% pay before shipment |

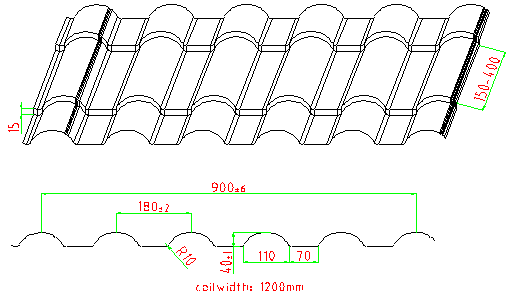

3. Profile drawing

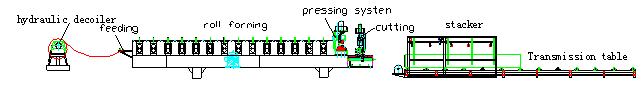

4. The Chart of Process Flow

5. Specification of Components

(1) 5T Hydraulic Un-coiler

(2) Coil Car

(3) Main Roll Forming Machine

(4) Machine Structure

(5)Pressing System:

(6) Hydraulic cutting system

(7) Computer Control Cabinet

Warranty

1: Guaranteed against malfunctions due to manufacturing defects for 1 year after date of shipment. Repairs will be made free of charge.

2: Repairs will not be performed free of change even during the guarantee period in the follow circumstances

- Damage occurs due to a natural disaster

- Malfunction occurs due to user error

- Malfunction occurs due to modifications

- Malfunction occurs due to further movement or shipment after installation

3:Air ticket, transportation cost, hotel, meals and 100$ per day shall be for purchaser’s account if manufacturer’s engineer has to be send to purchaser’s factory to maintain the machine during the guarantee period.

5. FAQ

1) Q: Are you manufacturer or trading company?

A: We are manufacturer and trading company .

2) Q: Do you provide installing and training overseas?

A: Overseas machine install and worker training services are optional.

3) Q: How is your after sales support?

A: We provide technical support on line as well as overseas services by skillful technicians.

4) Q: How does your factory do regarding quality control?

A: There is no tolerance regarding quality control. Quality control complies with ISO9001. Every machine has to past testing running before it's packed for shipment.

5) How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference. Or,

2) We welcome you visit us and test machine by yourself in our factory.

6) Q: Do you have this roof panel roll forming machine in stock?

A: No, machine is made to order.

|