| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roll Forming Equipment |

|---|---|

| Brand Name: | Sussman |

| Model Number: | RF-SH |

| Certification: | CE, SGS, ISO |

| Place of Origin: | Wuxi, China |

| MOQ: | 1 set |

| Price: | negotiable |

| Payment Terms: | LC, TT |

| Supply Ability: | 10 sets/ months |

| Delivery Time: | 60 days after deposit |

| Packaging Details: | Film and steel |

| material thickness: | 0.3-0.8mm |

| Forming speed: | 8-12m/min |

| Roller stations: | 18 stations |

| Roller material: | GCr15, coated with chrome |

| main motor power: | 7.5Kw |

| name: | Double Deck Roll Forming Machine |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Advantage of machine

1. Reasonable Price

2. High Quality

3. 12 Months Warranty

4. More Than 10 Years Experience

5. Durable

6. Reliable

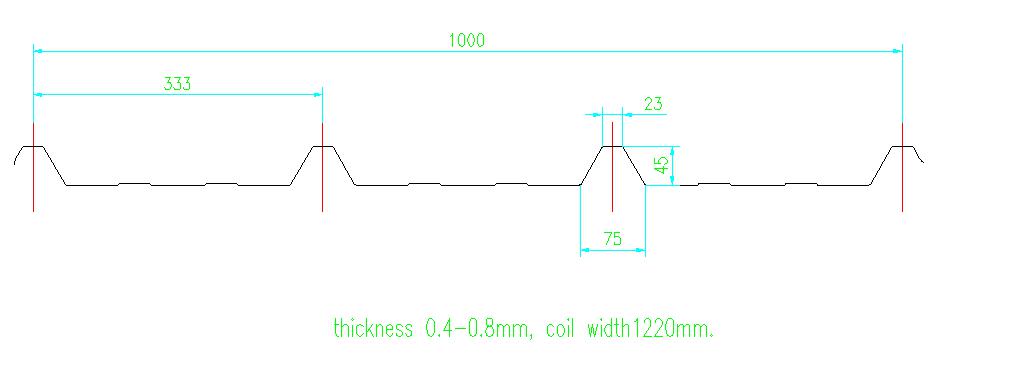

1. Suitable Plate Material: thickness 0.3-0.8mm, Galvanized steel S235JR

2. Working Speed: 8-12meters / min

3. Forming machine: 18 stations

4. Material of Roller: Gcr15, Quench HRC58-62 Plated Chrome

5. Material of Shaft: 45# Advanced Steel (Diameter: 76mm), thermal refining

6. Driven system: Chain Driven 1.2 inches 20A double chain with longer shafts

7. Main Power with reducer: 7.5KW

8. Cutting: Hydraulic Cutting Cr12mov

9. Material of Cutting Knife: Cr12Mov, Quench HRC58-62

10. Hydraulic Station Power: 5.5KW

11. The whole machine is controlled by industry computer-PLC.

12 PLC--Panasonic, Japan English and Chinese Language

13. Touch Screen--Panasonic Japan

14. Encoder--Omron, Japan

15. Electric parts--Schneider

16. Outline of main about 4000mm*1350mmm*1200mm

17. Weight : about 12 tons

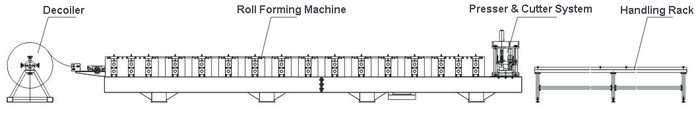

Main Components

Serial No. | Commodity & Description | Quantity |

1 | 5T manual uncoiler | 1 set |

2 | Leveing guiding | 1 set |

3 | Servo feeding device | 1 set |

4 | Main roll forming machine | 1 set |

5 | Hydraulic station | 1 set |

6 | Cutting device | 1 set |

7 | Finished products tabel | 1 set |

8 | PLC control system | 1set |

9 | Out tables | 1 set |

10 | Spare parts | 1 set |

Working Flow of Roll Forming Machine

A.Passive

Decoiler..........................................................To

load and uncoiling material

(We also have Electric Decoiler and Hydraulic Decoiler to hold the

heavy material.)

B.Servo Feeding Applicator............................................To feed the material accurately

C.Hydraulic/Press Punching...........................................To punch as requirements

D.Roll Forming Unit.........................................................To roll form as requirements

E.Hydraulic

Cutting.........................................................To

cut sheets as desired length

(We also have non-stop hydraulic cutting system.)

F.Output Table................................................................Support the finished products

Uncoiling—Feeding&Leveling--Roll forming—Cutting—Products collecting

Profile of product

Pictures

|