| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roll Forming Equipment |

|---|---|

| Brand Name: | Sussman |

| Model Number: | RF-ST |

| Certification: | CE, SGS, ISO |

| Place of Origin: | Wuxi, China |

| MOQ: | 1 set |

| Price: | negotiable |

| Supply Ability: | 10 sets/month |

| Delivery Time: | 60 days after deposit |

| Packaging Details: | Film and steel |

| steel strip thickness: | 1-2.5mm |

| Forming speed: | 0-90m/min |

| high frequency equipment power: | 200Kw |

| Equipment motor: | 173Kw |

| High frequency motor: | 200Kw |

| Company Info. |

| Sussman Machinery(Wuxi) Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Forming Speed 90m/min Weld Tube Mill Thickness 0.8-2.5mm

1. Introduction

This equipment is specially used for producing Φ20-Φ76mm,δ0.8-2.5mm high-frequency

straight seam welded pipe and corresponding square pipe and special-shaped pipe(δ≤2.0mm).

The composition of equipment is from decoiler to fixed length cutting saw. Rolling speed can be adjusted

correspondingly within suitable range of pipe diameter and wall thickness.

2. Technical Parameter

Machine List:

| No. | Name | Quantity |

| 1 | Single head hydraulic tensioning Decoiler | 1 |

| 2 | Shear & butt-welder | 1 |

| 3 | horizontal accumulation | 1 |

| 4 | Forming and sizing section | 1 |

| 5 | Computer-controlled cutting saw | 1 |

| 6 | Run out table with power roller(12m) | 1 |

| 7 | 300kW solid state high frequency welder | 1 |

3. Flow Chart

Raw material (steel coil) → decoiling→ shearing and welding→ accumulator → non-power leveling →forming

milling →high frequency welding →de-burr frame→ cooling unit→ sizing unit →rough straightening → fixed

length cutting →run out table

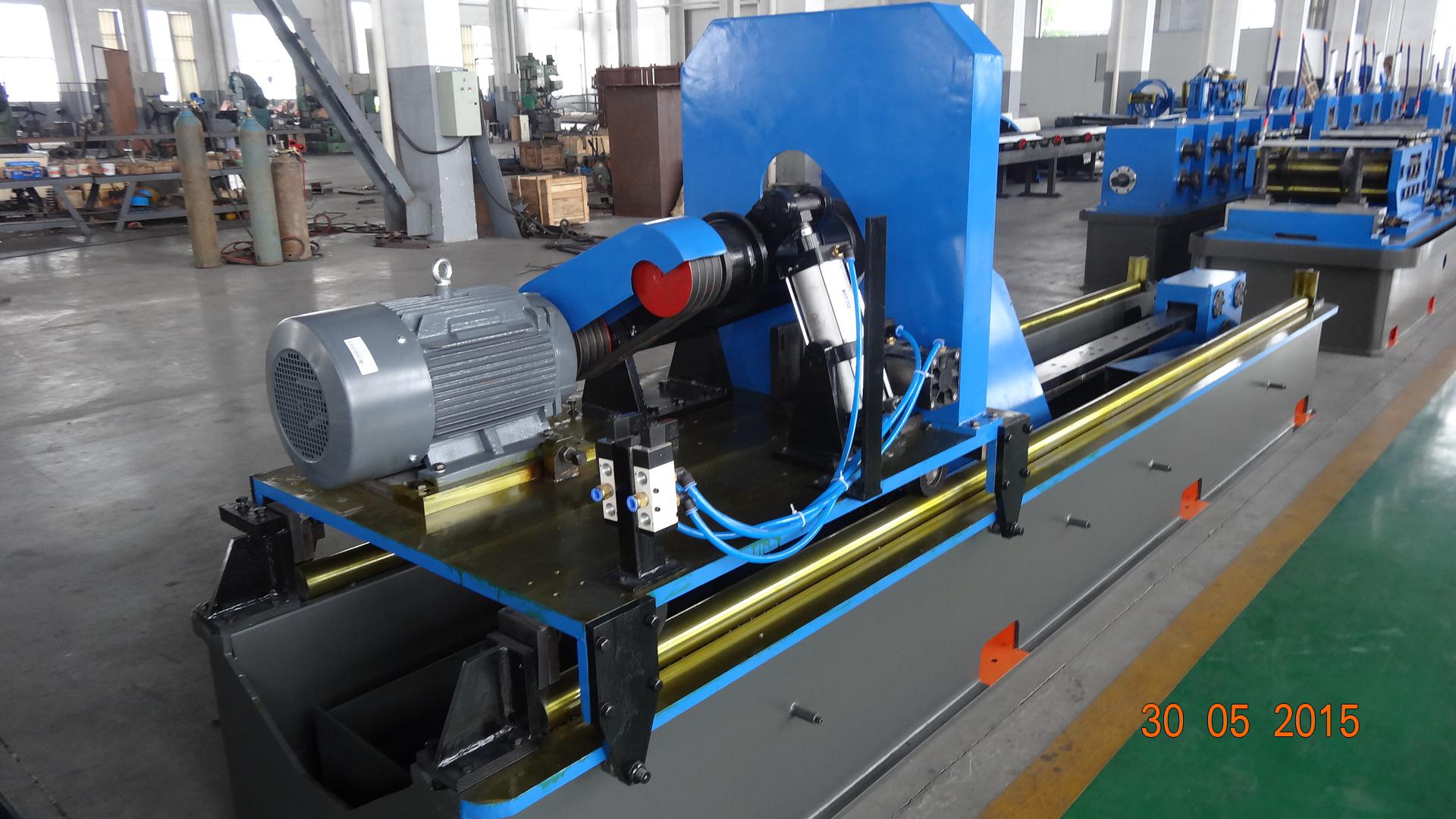

4. Machine Photo

5. Loading Pics

6. Company Introduction

Sussman Machinery (wuxi) Co., Ltd. is a comprehensive enterprise integrating production, sales and services. We are mainly engaged in providing machineries and equipment. Owing to a professional teamwork, we are experienced in manufacturing, import and export, customers' design, installation and test, technical solution and after-sale services. We have shipped out our machines to more than 50 countries, and keep good business relationships with a large amount of worthy customers, contributing to our great business records and reputation.

|