| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Cross Laminated Film |

|---|---|

| Place of Origin: | Shanghai, China |

| Brand Name: | Upass |

| Model Number: | SDM |

| MOQ: | 50000 square meters |

| Price: | $0.32/square meters 50000-99999 square meters |

| Processing Service: | Cutting |

| Product name: | Strong Cross Laminated HDPE Release Film |

| Application: | Waterproofing Membranes, tapes, labels |

| Thickness: | 0.1mm-0.26mm |

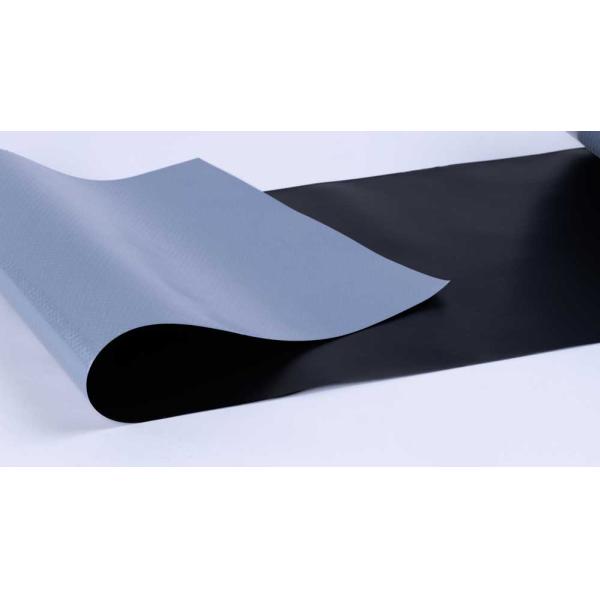

| Color: | Blue, Green, Black, Grey, White, Green/Black, Grey/Black |

| Certificate: | ISO9001:2018 |

| Company Info. |

| Upass Material Technology (Shanghai) Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

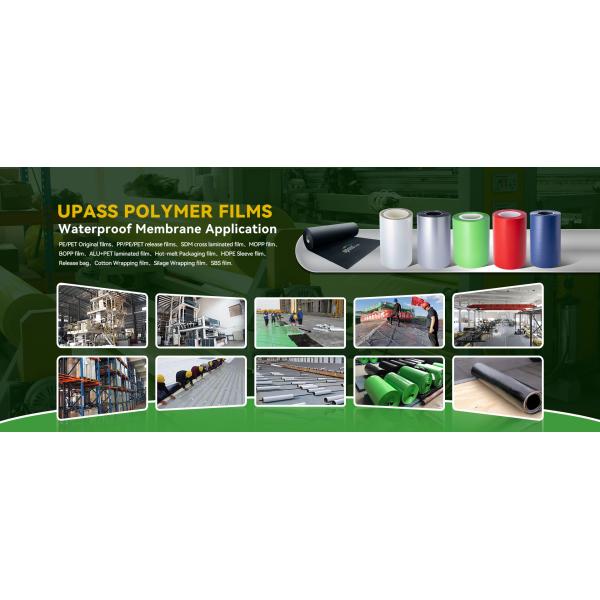

HDPE cross laminate film is an advanced waterproof material manufactured through special cross-lamination technology using high-density polyethylene (HDPE). Its unique crisscross structure delivers exceptional tensile strength, puncture resistance and dimensional stability, making it ideal for construction waterproofing, civil engineering and environmental protection applications.

Superior Strength: Balanced orientation strength (MD & CD).

Perfect Waterproofing: 100% anti-seepage

Excellent Weather Resistance: UV stabilized, wide temperature range, 50+ years service life

Eco-Friendly: Food-grade raw materials, non-toxic

Easy Installation: Lightweight and flexible, compatible with heat welding and adhesive bonding

As a core material for modern waterproofing solutions, our HDPE cross laminate membranes are ISO 9001 certified, thicknesses with customizable options. Contact us today for free samples and technical support!

| NO. | Item | Performance | ||

| SDM-30 | SDM-60 | |||

| 1 | Tensile Property | Tensile Strength/Mpa ≥ | 30 | 50 |

| MaxF/(N/50mm) ≥ | 200 | 300 | ||

| Elongation as MaxF/% ≥ | 200 | |||

| Elongation at break/% ≥ | 250 | |||

| 2 | Sample number of no broken tested by free-falling dart method ≥ | 8 | ||

| 3 | Tear Strength(Nail Shank)/N ≥ | 60 | ||

| 4 | Angle Tear Strength/N ≥ | 25 | ||

| 5 | Thermal Stability | 120 ℃,10min, No bulb, No deformation | ||

| 6 | Cryogenic Flexibility ℃ | -35℃, No fissure, No delamination | ||

| 7 | Thermal Ageing | Appearance | No bulb, No deformation | |

| Subsequent MaxF/% ≥ | 80 | |||

| Elongation at MaxF/% ≥ | 200 | |||

| Elongation at break/% ≥ | 200 | |||

| 8 | Artificial Weathering | Appearance | No bulb, No deformation | |

| Subsequent MaxF/% ≥ | 70 | |||

| Elongation at MaxF/% ≥ | 180 | |||

| Elongation at break/% ≥ | 180 | |||

|