| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Roofing Sheet Roll Forming Machine |

|---|---|

| Brand Name: | ZHONGHENG |

| Model Number: | ZH840 |

| Certification: | CE/SGS/ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 set |

| Price: | USD11000-15000/set |

| Payment Terms: | Western Union, T/T, L/C |

| Supply Ability: | 300 sets/months |

| Delivery Time: | 25working days |

| Packaging Details: | Waterproof plastic film cover |

| Feeding Width: | 1000 mm or custom |

| Models: | 840 roofing |

| Forming Stations: | 11 |

| Certificate: | CE |

| Control system: | PLC control |

| Machine structure: | 350 H beam |

| Chains: | 1 inch |

| Speed: | 10-15 m/min |

| PLC brand: | panasonic |

| type: | Glazed Tile Roll Forming Machine |

Color Roof Panel Steel Sheet Roll Forming Equipment Machine For

Roofing sheet

Machine Pictures

Profie panel pictures

Specifications

The machine is standard machine for roofing use.Its popular in

China market and south America market.

The main advantages of kexinda double layer corrugated machine

price :

•Variable frequency speed control

•Multi-purpose for overlap connection

•Auto power off.

|

| Voltage | 380v/3ph/50hz |

| Main Motor power | 4kw | ||

| 2 | Forming speed | 8-15m/min | |

| 3 | Forming stations | 11 | |

| 4 | Thickness of structure | 16mm | |

| 5 | Forming shaft diameter | 70mm | |

| 6 | Chains | 1 inch | |

| 7 | H steel | 350mm | |

| 8 | Sleeve | galvanized pipe with color coating | |

| 9 | Screen | Text screen /touch screen | |

| 10 | Type of cutting | Roll formed and length-set cutting | |

| 9. | Control system | PLC Delta and Inveter Delta | |

| 10. | Install dimension(depend on the final design) | 8.2m×1.5m×1.2m | |

| 11. | Total weight (Approx) | 6.5T | |

No | Name | Quantity | Remarks | |

1 | Decoiler | 1set | Up to customer | |

2 | Main machine | Pre-cutting device | 1set | Up to customer |

Feeding device | 1set | |||

Roll forming system | 1set | |||

Post cutting device | 1set | |||

Hydraulic system | 1set | |||

3 | Electric control system | 1set | ||

4 | Supporter / Automatic Stacker | 1set | ||

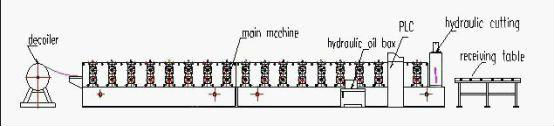

Flow Chart

Uncoiling→Feeding material into machine→Roll forming→Measuring

length→ Auto cutting→

Products receiving

Machine Components

Description

1. Material of rollers:45# steel,roller surfaces polishing, hard

plating

The polished surface and the heat treatment towards the molds also

can keep the molding plate surface

smooth and not easy to be marked when it is being stamped.

2.We have a professional design team

3.Can also design and manufacture according to customer's

requirement

Competitive Advantage:

| 1. Professional | 15 years' rich experience! |

| 2. Low price | Save your money from every part! |

| 3. PLC | Ensuring high accuracy and easy to operate! |

| 4. OEM / ODM | Customers’design, color & logo are also accepted! |

| 5. One-Years warranty, whole life service | Keep troubles far away from you! |

|