| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Auger Screw Conveyor |

|---|---|

| Brand Name: | EVERSUN |

| Model Number: | EDS |

| Certification: | ISO,CE |

| Place of Origin: | CHINA |

| MOQ: | 1set |

| Price: | negotiable |

| Payment Terms: | L/C,D/A,D/P,T/T,MoneyGram,Western Union |

| Supply Ability: | 5000set/year |

| Delivery Time: | within 7-15 work days |

| Packaging Details: | Standard export wooden cases |

| Noise: | ≤70db |

| Main Function: | Lift conveying |

| Conveying Angle: | 0~90° |

| Size: | Customized |

| Advantage: | Cover a small area |

| Material: | Stainless Steel |

| Colour: | Sandblasting customization |

| Installation: | Simple and quick installation |

| Suitable For: | Powders, granules, and other bulk materials |

| Warranty: | 1 year |

| Usage: | Food processing, chemical industry, agriculture, mining, and more |

| Keywords: | Vertical spiral conveyor |

| Company Info. |

| EVERSUN Machinery (Henan) Co., Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

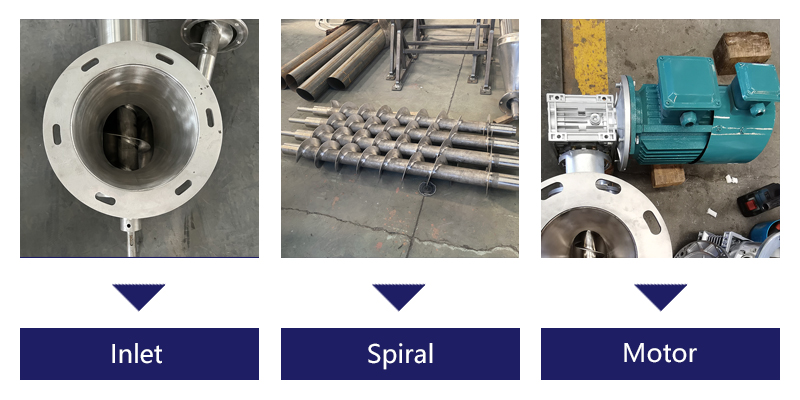

Product description

The screw conveyor is a continuous conveying equipment that uses

the rotating screw blade to push materials forward along the trough

of the casing. It is widely used in agriculture, mining,

construction, chemical and other fields. Its structure mainly

consists of screw blades, casing, drive device and inlet and outlet

ports. It has the characteristics of simple structure, small

cross-sectional size, good sealing, convenient operation and easy

maintenance. It can convey powder, granular and small block

materials such as flour, grains, sand and gravel, and coal powder

horizontally, inclined or vertically. It can effectively reduce the

scattering and pollution of materials during the conveying process

and undertake the short-distance transportation and distribution of

materials in the production line.

Working principle

When the driving device (such as a motor) drives the spiral shaft

to rotate, the spiral blades fixed on the shaft rotate

synchronously. Due to the certain gravity and internal friction of

the materials, and the constraint of the machine shell groove body

on the materials, the materials do not rotate along with the spiral

blades but move forward along the inner wall of the machine shell

under the thrust of the blades.

During this process, the helical surface of the spiral blades

continuously exerts axial thrust on the materials, causing the

materials to be gradually transported from the feed port to the

discharge port. Depending on the different conveying directions,

the rotation direction of the spiral blades (left-handed or

right-handed) and the rotation direction of the shaft can be

adjusted to achieve horizontal, inclined or vertical material

transportation. At the same time, the sealing structure of the

machine shell can reduce the scattering and dust generation of the

materials during the conveying process, ensuring the efficiency and

environmental friendliness of the conveying process.

Product characteristics

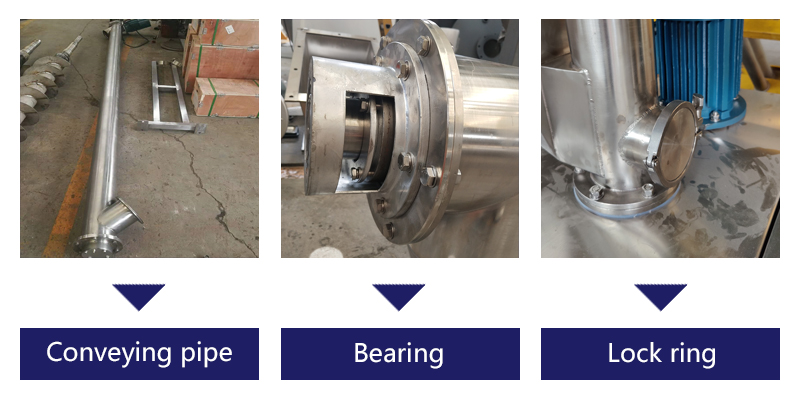

1. The structure is simple, easy to manufacture and maintain. It

mainly consists of spiral blades, casing, drive device, etc. With

few components, the processing and installation are relatively

easy. Daily maintenance only requires regular checks on blade wear,

bearing lubrication, etc., and the cost is relatively low.

2. The cross-sectional size is small, saving space. The body is

compact and can be installed in narrow spaces. It is particularly

suitable for scenarios with dense production line layouts and can

effectively utilize factory space.

3. Good sealing performance, reducing pollution. The casing is

mostly of a sealed design, which can reduce the scattering, dust

flying or odor diffusion during material transportation, and is

suitable for transporting materials with a lot of dust, easy

pollution or volatility.

4. Flexible transportation direction. It can not only be

horizontally transported, but also tilted or vertically

transported, which can meet the requirements of different process

layouts and achieve multi-angle transfer of materials.

5. Easy operation and strong controllability. By adjusting the

rotational speed of the drive motor, the transportation volume can

be flexibly controlled, and it can also be linked with other

equipment (such as silos, screening machines) to achieve automated

production.

6. Suitable for various material types. It can transport powdery,

granular, and small block materials, with a wide range of

applicability.

Product parameter

| ||||||||||||||||||||||||

Production line diagram

1.The screw conveyor transport the mixed material from the ribbon

mixer to a horizontal screw conveyor

2.The horizontal screw conveyor with 3 outlets, each outlet equip

with a butterfly valve, when you need filling a bulk bag, just open

that butterfly valve

3.The platform cam add weighing sensor if you need

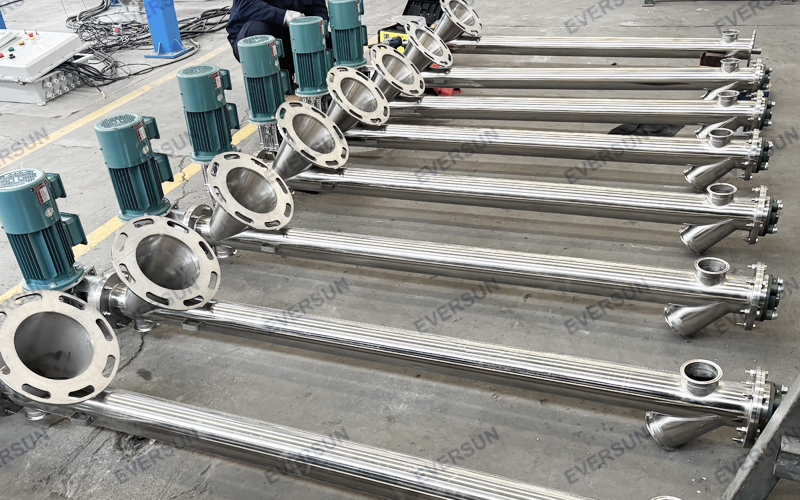

Product display

Product details

Product application

Packaging & Shipping

Why Choose us

About us

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry top three. And we have done

matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM

for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.Our factory address: West of the industrial and commercial office of Da

Zhaoying Town, Xinxiang City, Henan Province.

|