Screw Conveyor

Product description

A screw conveyor is a conveying equipment that pushes materials in

a closed shell by rotating screw blades. Its core structure

consists of a screw shaft, U-shaped or tubular material troughs, a

drive device and bearings. It can achieve material transmission in

horizontal, inclined (inclination Angle ≤20°) or vertical

directions. It has the advantages of compact structure and

space-saving, sealed conveying to prevent dust, and the conveying

capacity can be adjusted by rotational speed. It is often used in

industries such as grain processing, chemical engineering, and

building materials to convey powdered and granular materials.

However, it has poor adaptability to sticky or large pieces of

materials, and when conveying over long distances, it needs to be

arranged in sections. This kind of equipment occupies an important

position in industrial material transmission due to the high

efficiency of mechanical transmission and the flexibility of

structural design.

Working principle

The working principle of a screw conveyor is as follows: The drive

device rotates the screw shaft, causing the screw blades to rotate

synchronously. After the material enters the shell, it moves

axially and directionally under the combined action of the blade

thrust, the shell friction force and the centrifugal force (when

conveying at an inclined or vertical Angle). When conveying

horizontally, it is directly pushed by the blades; when conveying

at an inclined or vertical Angle, it needs to overcome gravity.

Among them, the friction between the shell and the material can

prevent the material from idling along with the blades, ensuring

the conveying efficiency. This principle makes it more adaptable to

powdery and granular materials, while when conveying viscous

materials, special structures such as variable-pitch blades need to

be adopted to avoid clogging.

Product characteristics

1. Compact structure: Small footprint, suitable for installation in

narrow Spaces.

2. Sealed and environmentally friendly: The fully enclosed shell

prevents dust leakage and is suitable for clean environments.

3. Flexible direction: It can be conveyed horizontally, at an

incline (≤20°) or vertically, and supports multi-stage rotation.

4. Controllable conveying: The conveying capacity can be adjusted

by rotational speed, making it suitable for quantitative conveying

of powdery/granular materials.

5. Easy maintenance: The components are simple, wear is easy to

inspect, and the replacement cost is low.

6. Obvious limitations: It is not suitable for sticky or large

pieces of materials. For long distances, it needs to be segmented.

The energy consumption for inclined conveying increases with

height.

Product parameter

| Model | Conveying tube diameter | Power | Hopper volume | Angle(Degree) | | ESC-133 | 133mm | 0.75-4KW | 200L or customized | 30-60 | | ESC-159 | 159mm | 0.75-4KW | | ESC-219 | 219mm | 1.5-4KW | | ESC-273 | 273mm | 2.2-4KW | | Please consult us for more models |

|

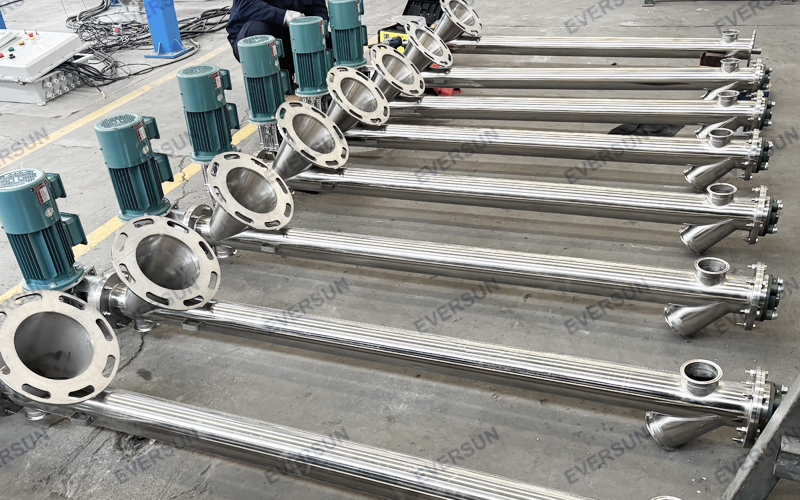

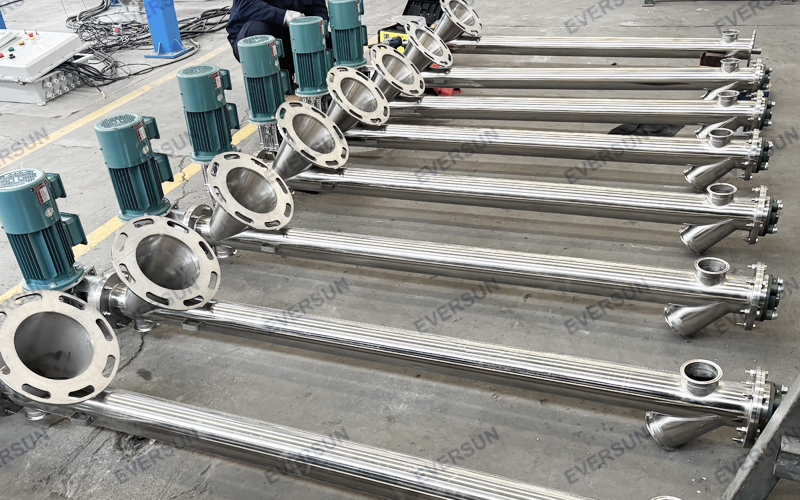

Product display

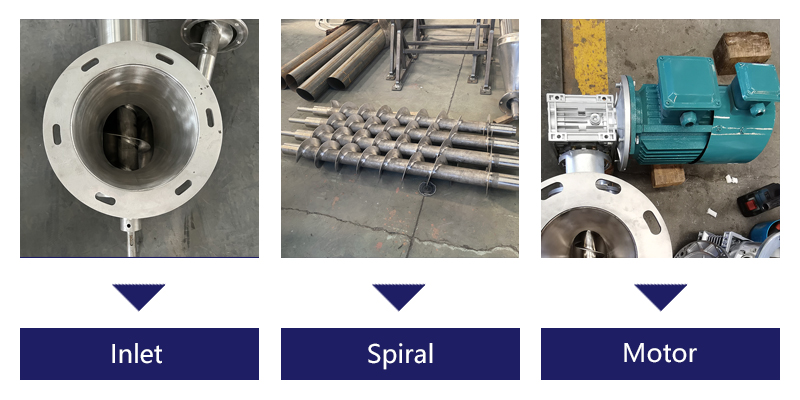

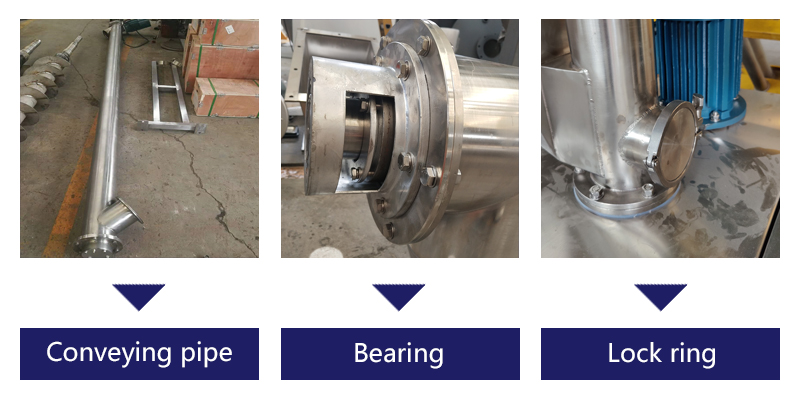

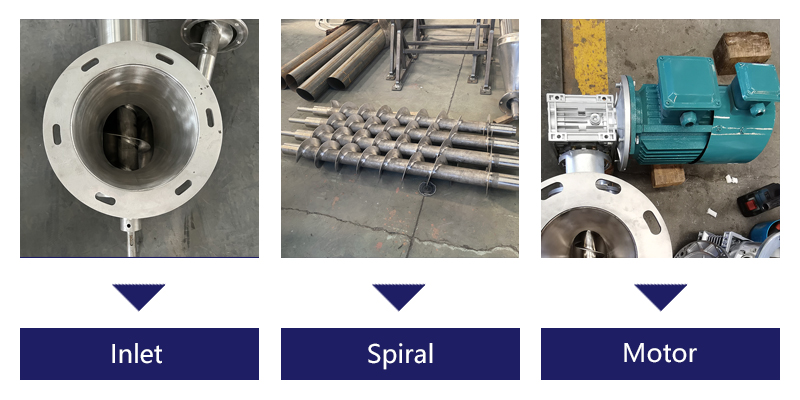

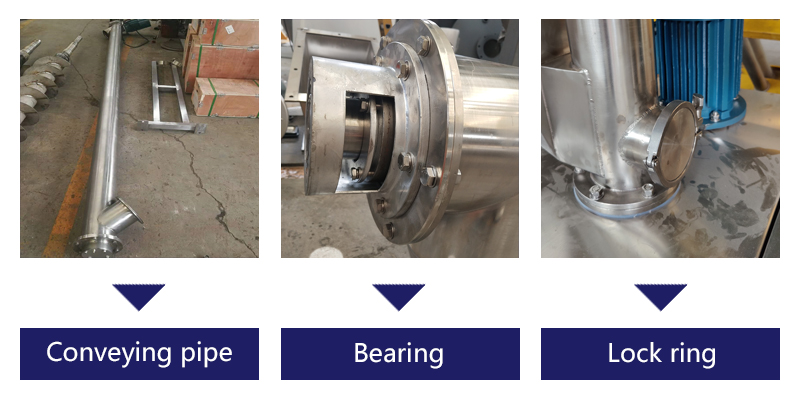

Product details

Product application

Packaging & Shipping

Why Choose us

About us

We have been specializing in the production of Screening and

conveying equipment for 13 years. China's vibrating screen industry top three. And we have done

matching and OEM for many large companies. Including the world's top vibrating screen manufacturer,

Sweco, USA, we have OEM

for his China region. And our products are often exported to

Australia, Thailand, Indonesia, New Zealand and other countries.

We welcome customers or dealers to visit our factory and will

arrange everything for you.Our factory address: West of the industrial and commercial office of Da

Zhaoying Town, Xinxiang City, Henan Province.