| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Reverse Wedge Wire Screen |

|---|---|

| Brand Name: | Hengyuan |

| Model Number: | HY062203 |

| Certification: | CE,ISO,CIQ,CO,FORM E,CCPIT |

| Place of Origin: | Hengshui City,Hebei Province |

| MOQ: | 2 Pieces |

| Price: | USD 50-200 per piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | More than 20 PCS per day |

| Delivery Time: | 5-8 work day |

| Packaging Details: | Wooden box |

| Name: | Full Weld Wedge Wire Screen |

| Material: | Stainless Steel |

| OD: | 125mm |

| Length: | 255mm |

| Slot: | 0.09mm |

| Wire size: | 1*2mm Vee wire |

| Support rod: | 2*3mm Vee wire |

| Distance of rods: | 10mm |

| Ends: | No ends |

| Filter type: | FITO |

| Surface: | Acid washing |

| Package: | Wooden box |

| Company Info. |

| Anping County Hengyuan Hardware Netting Industry Product Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Full Weld Wedge Wire Screen, also called wedge wire cylinder, is a type of cylindrical "V" shape wedge wire screen, which is made of stainless steel VEE shaped wires and support rods.

As the wedge wire rotary drum screen is working under high pressure when separation and filtration, so there is reinforced rods on the structure.

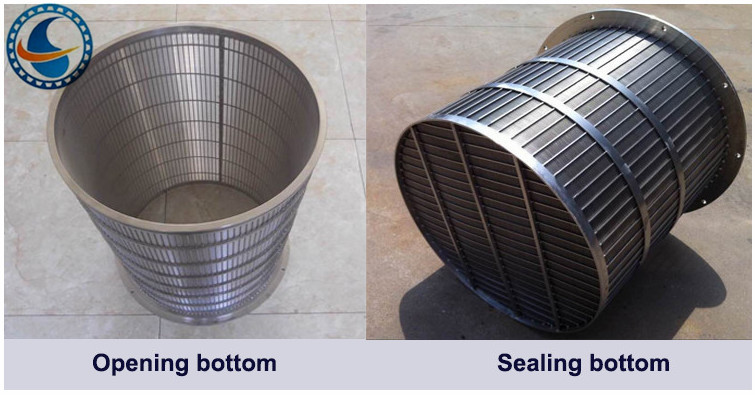

The end of rotary drum wire screen is welded flanges or welded rings for easy installation.

The slot sizes and structures may varies according to different materials and working conditions.

The wedge wire screen is installed on the roller screen machine. Drive the internal blades by motor to compress the filtration subjects and separate the particles and liquid with rotary drum wire screen (wedge wire screen). Click for detailed working principle of rotary drum screen in water treatment.

Outside Diameter (mm) | Length (mm) | Slot (mm) | Type of end connection |

29,38,57,63,76,89,108, 150,168,320,600 etc | 500,1000,2000 etc | 0.025,0.1,0.25,0.5,1.0 etc | Welded rings, male/female threaded coupling,flange, closed up and so on |

Explanation | Besides above of the specification screen pipe, we also can act according to the customer’s request. Diameter: ø29mm-ø1300mm. The length from the 100mm-6000mm. | ||

|