| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Reverse Wedge Wire Screen |

|---|---|

| Brand Name: | Hengyuan |

| Model Number: | HY032602 |

| Certification: | CE,ISO,CIQ,CO,FORM E,CCPIT |

| Place of Origin: | Hengshui City,Hebei Province |

| MOQ: | 2 Pieces |

| Price: | USD 50-200 per piece |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | More than 20 PCS per day |

| Delivery Time: | 5-8 work day |

| Packaging Details: | Wooden box |

| Name: | Profile Wedge Wire Screw Press Baskets |

| Material: | Stainless Steel 304 |

| ID: | 72mm |

| OD: | 80mm |

| Length: | 362mm |

| Slot: | 0.3mm |

| Wire size: | 1.2*2mm Vee wire |

| Support rod: | 2*3mm Vee wire |

| Ends: | Nothing |

| Filter type: | FITO |

| Company Info. |

| Anping County Hengyuan Hardware Netting Industry Product Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

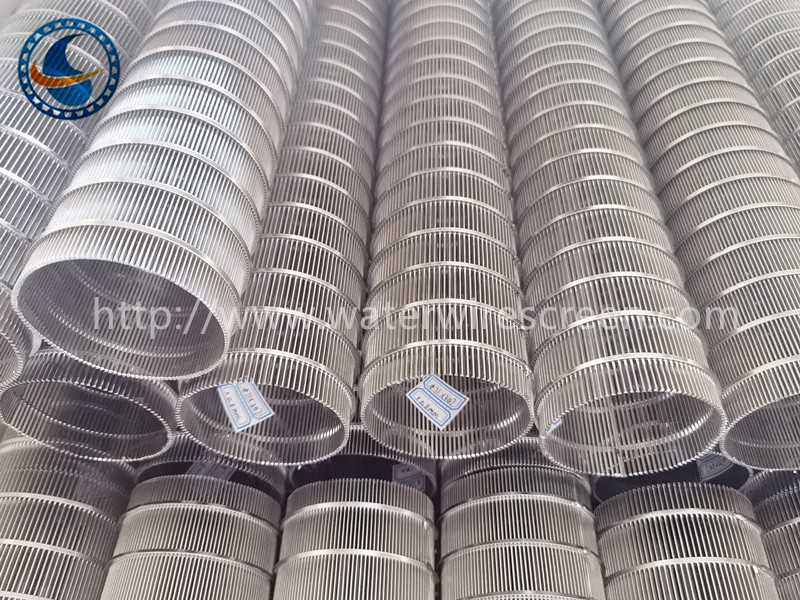

Stainless Steel 304 Profile Wire Wedge Wire Screw Press Baskets

Profile Wedge Wire Screw Press Baskets are custom designed to fit all makes and models. HENGYUAN designs and manufactures a screw press basket to fit your needs. Our baskets, are high-strength, drilled hole and Vee-Wire Shaped slotted designs, which provide increased open area, greater fiber retention and better effluent clarity.

Profile Wire Wedge Wire Screw Press Baskets Characteristis:

Custom Designed

High Strength

Drilled Hole

Machine Slot

Wedge wire

Increased open area

Better Fiber retention

Increased effluent clarity

Kinds of materials

Outside Diameter (mm) | Length (mm) | Slot (mm) | Type of end connection |

29,38,57,63,76,89,108, 150,168,320,600 etc | 500,1000,2000 etc | 0.05,0.1,0.25,0.5,1.0 etc | Welded rings, male/female threaded coupling,flange,closed up and so on |

Explanation | Besides above of the specification screen pipe, we also can act according to the customer’s request the manufacture diameter from ¢ 29mm- ¢ 1000mm, the length from the 100mm-4000mm series screen pipe | ||

Profile Wire Wedge Wire Screw Press Basketsare made with high-quality stainless steel wire strip processing into a trapezoidal section, winding through automated production equipment, on the support bar, and then processed by cutting, welding and other processes to form a screening product.

|