| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | XYZ Linear Actuator |

|---|---|

| Brand Name: | SXEGL |

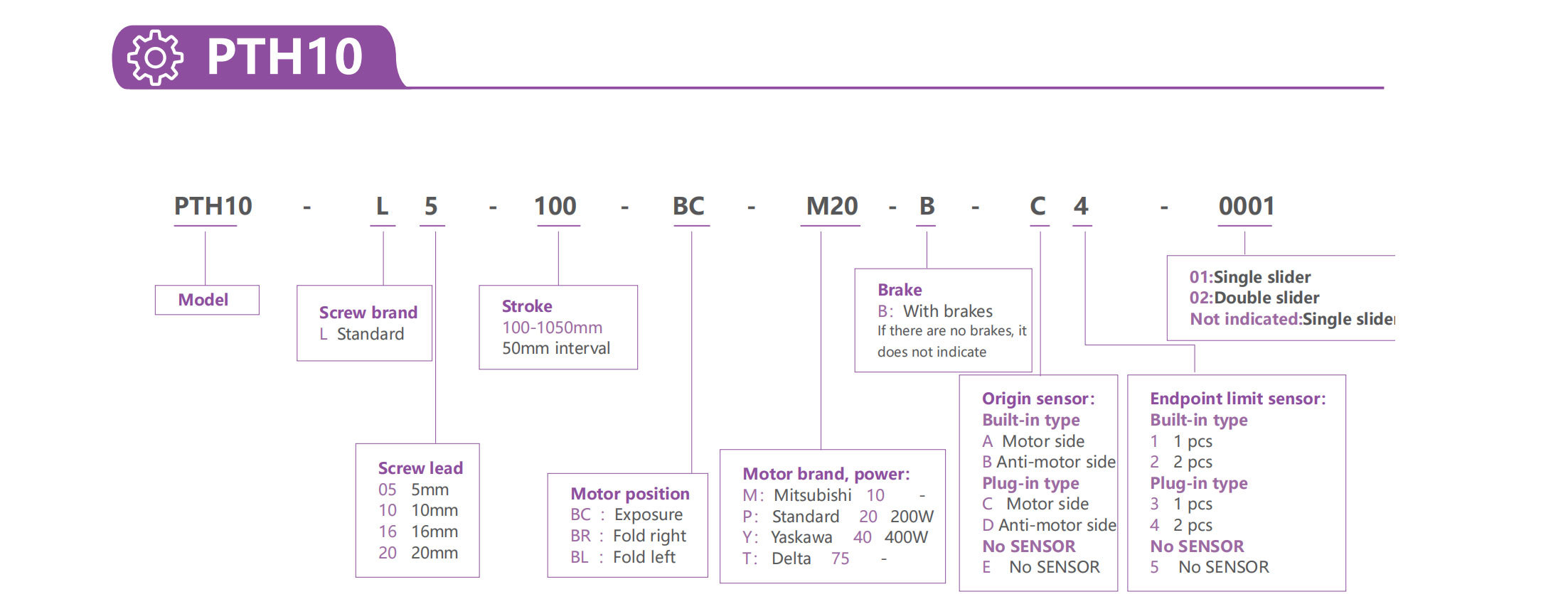

| Model Number: | PTH10 |

| Certification: | CE/FCC/EPA/ROSH/ISO |

| Place of Origin: | China |

| MOQ: | 1 |

| Packaging Details: | Carton |

| Delivery Time: | Small orders usually takes 3-7 days,big order usually 20-35 days, depending on orders quantity and whether are standard size. |

| Payment Terms: | Visa /Mastercard/PayPal/Apple Pay/Google Pay |

| Supply Ability: | All products have passed CE certification and comply with EU RoHS environmental standards |

| Price: | $1-$9999 |

| Name: | Multi Axis Actuator |

| Series: | PTH |

| Stroke Range: | 50mm-1500mm |

| Position Accuracy: | 0.02mm |

| Max Speed: | 500mm/s |

| Max Load: | 100kg |

| Ball Screw: | G1610A/G2020 |

| Company Info. |

| SXEGL Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Multi Axis Precision Interchangeable XYZ Linear Actuators Heavy Load Synchronization

Product Overview

As a core equipment in industrial automation, multi-axis robots integrate 2-6 degrees of freedom to enable precise positioning and complex trajectory motion in 3D space. This series of products combines high-rigidity mechanical structures, intelligent control systems, and modular designs, allowing rapid adaptation to scenarios such as electronic assembly, precision machining, material handling, and visual inspection. It delivers flexible and intelligent motion control solutions for high-end manufacturing.

| ※ Basic specifications | ||||||

| Specification | Standard motor power (W) | 200W | ||||

| Repeatable positioning accuracy(mm) | ±0.01 | |||||

| Screw specification | 1605 | 1610 | 1616 | 1620 | ||

| Max speed (mm/s) | 250 | 500 | 800 | 1000 | ||

| Rated thrust (N) | 683 | 341 | 213 | 174 | ||

| Max load (kg) | Horizontal | 50 | 30 | 22 | 18 | |

| Vertical | 12 | 8 | 5 | 3 | ||

| Max stroke (mm) | 1050 | |||||

| Component | Screw specification | 1605/1610/1616/1620(Slenderness ratio1:62.5) | ||||

| Screw grade | C7 rolling | |||||

| High rigidity linear slider | W20×H18 | |||||

| Coupling | 34-27-10-14 | |||||

| Photoelectric switch | PM-T45(NPN) | |||||

![]()

| (Unit:mm) (Unit:mm) | (Unit :mm) (Unit:N.m) | ||||||||||||||

|  |   | |||||||||||||

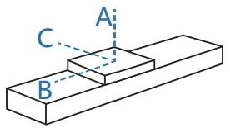

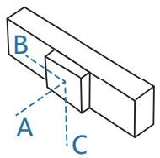

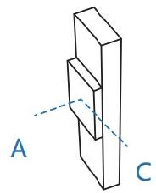

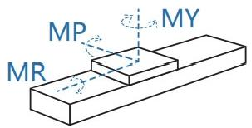

| Horizontal installation | A | B | C | Side installation | A | B | C | Vertical installation | A | C | MY | 110 | |||

| MP | 110 | ||||||||||||||

| Lead 05 | 30kg | 547 | 42 | 42 | Lead 05 | 25kg | 52 | 53 | 670 | Lead 05 | 5kg | 310 | 310 | MR | 120 |

| 40kg | 391 | 29 | 29 | 35kg | 35 | 45 | 455 | 8kg | 192 | 192 | |||||

| 50kg | 298 | 22 | 22 | 50kg | 21 | 22 | 298 | 12kg | 129 | 129 | |||||

| Lead 10 | 15kg | 521 | 84 | 80 | Lead 10 | 10kg | 124 | 131 | 770 | Lead 10 | 4kg | 335 | 335 | ||

| 25kg | 298 | 47 | 44 | 20kg | 58 | 61 | 382 | 6kg | 220 | 220 | |||||

| 30kg | 242 | 34 | 35 | 30kg | 35 | 37 | 242 | 8kg | 172 | 172 | |||||

| Lead 16 | 5kg | 937 | 282 | 259 | Lead 16 | 5kg | 116 | 58 | 605 | Lead 16 | 1kg | 620 | 620 | ||

| 10kg | 487 | 121 | 116 | 10kg | 24 | 26 | 253 | 2kg | 680 | 680 | |||||

| 22kg | 236 | 40 | 44 | 22kg | 0 | 0 | 0 | 5kg | 310 | 310 | |||||

| Lead 20 | 5kg | 675 | 224 | 193 | Lead 20 | 6kg | 160 | 185 | 562 | Lead 20 | 1kg | 580 | 580 | ||

| 10kg | 330 | 107 | 93 | 12kg | 76 | 88 | 272 | 2kg | 645 | 645 | |||||

| 18kg | 175 | 55 | 48 | 18kg | 48 | 55 | 175 | 3kg | 310 | 310 | |||||

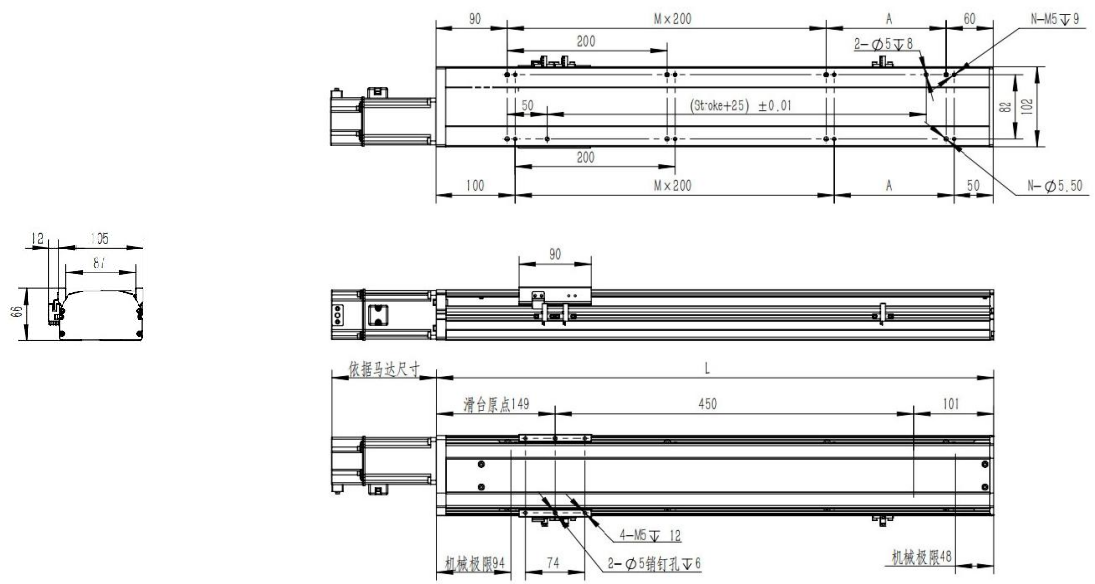

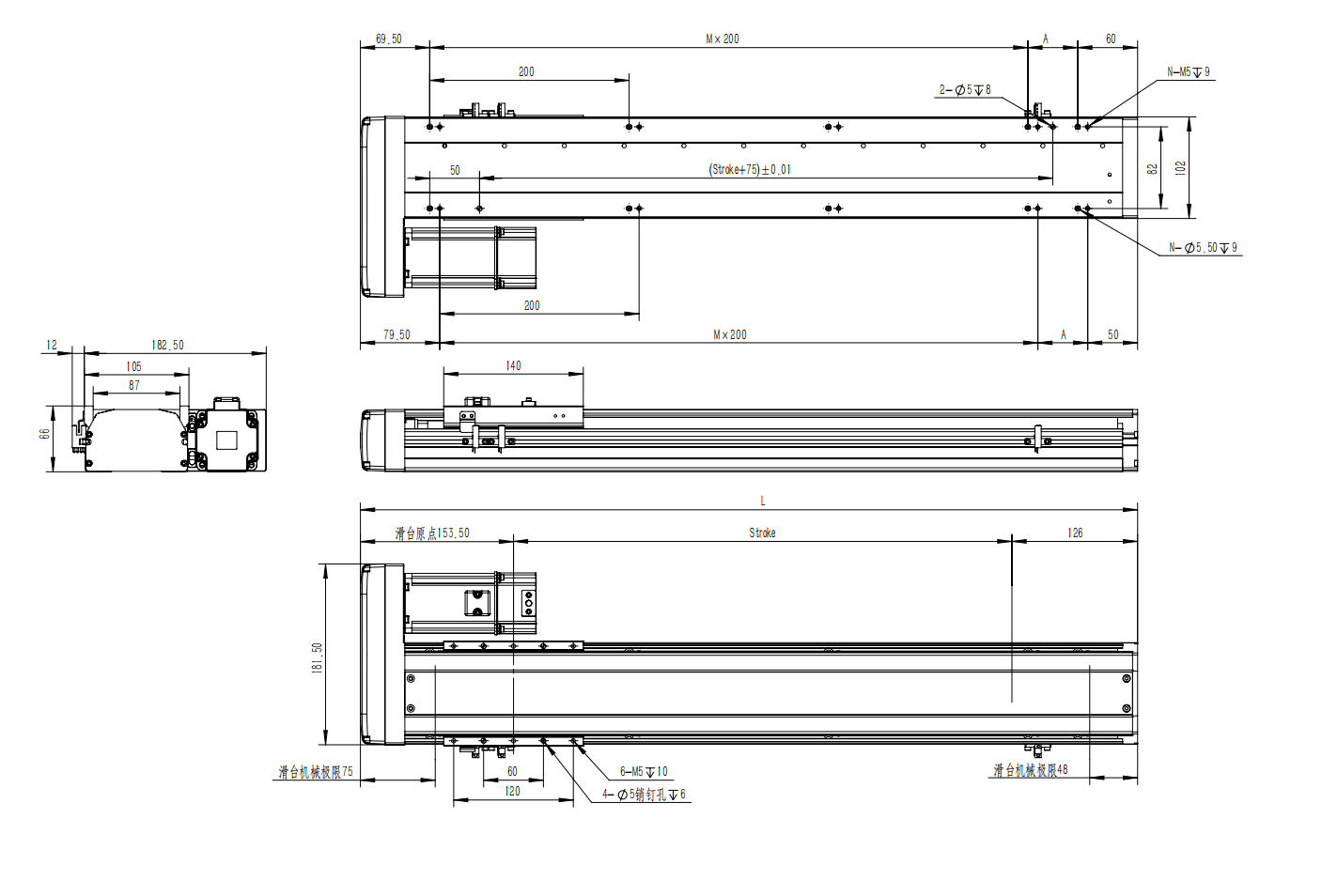

Motor exposure-01

| Unit:mm | ||||||||||||||||||||

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| L | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 |

| A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 |

| M | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 |

| N | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 |

| KG | 5.5 | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 |

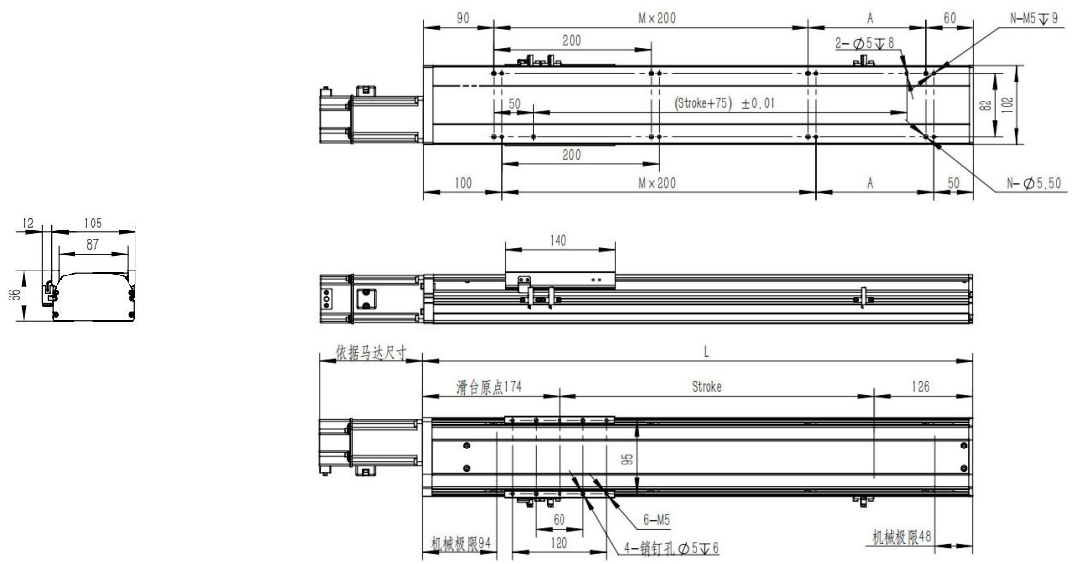

Motor exposure-02

| Unit:mm | ||||||||||||||||||||

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| L | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | 1100 | 1150 | 1200 | 1250 | 1300 | 1350 |

| A | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 |

| M | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 |

| N | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 14 |

| KG | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 | 13.2 |

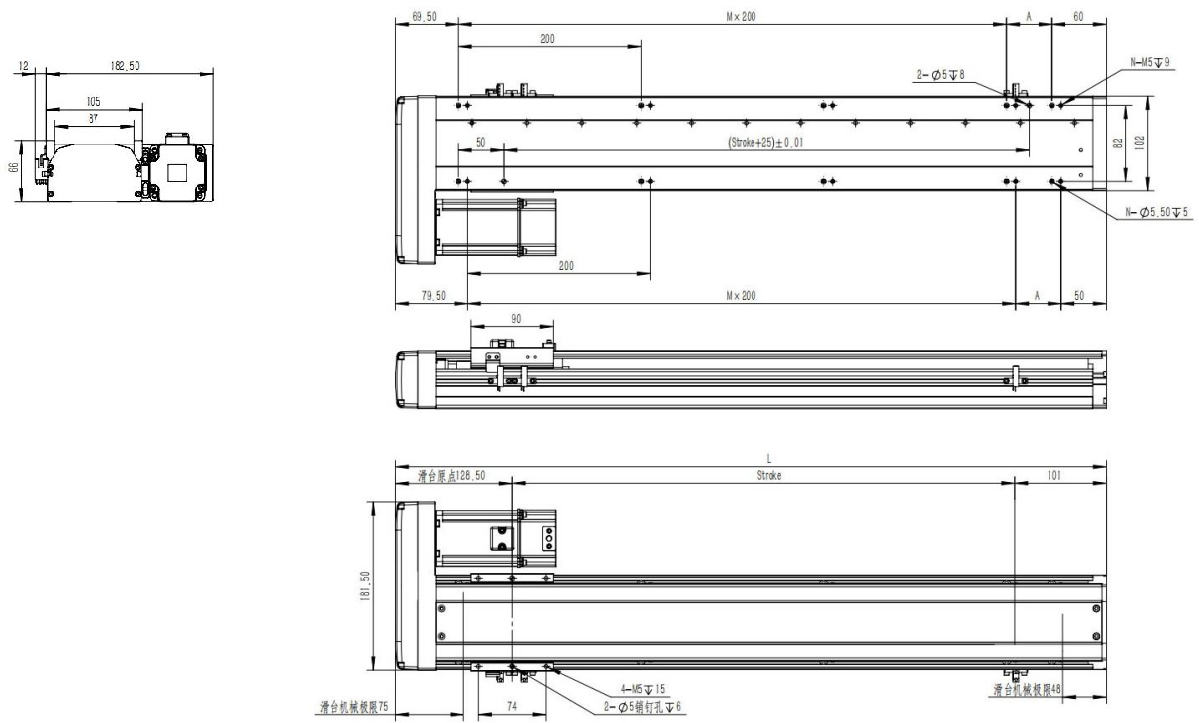

Motor folds right-01

| Note:The left fold of the motor is symmetrical with this figure Unit:mm | ||||||||||||||||||||

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 |

| L | 329.5 | 379.5 | 429.5 | 479.5 | 529.5 | 579.5 | 629.5 | 679.5 | 729.5 | 779.5 | 829.5 | 879.5 | 929.5 | 979.5 | 1029.5 | 1079.5 | 1129.5 | 1179.5 | 1229.5 | 1279.5 |

| A | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 |

| M | 0 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 |

| N | 4 | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 |

| KG | 5.5 | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 |

Motor folds right-02

| Note:The left fold of the motor is symmetrical with this figure Unit:mm | |||||||||||||||||||||

| Stroke | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 550 | 600 | 650 | 700 | 750 | 800 | 850 | 900 | 950 | 1000 | 1050 | |

| L | 379.5 | 429.5 | 479.5 | 529.5 | 579.5 | 629.5 | 679.5 | 729.5 | 779.5 | 829.5 | 879.5 | 929.5 | 979.5 | 1029.5 | 1079.5 | 1129.5 | 1179.5 | 1229.5 | 1279.5 | 1329.5 | |

| A | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | 50 | 100 | 150 | 200 | |

| M | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 4 | 4 | 4 | 4 | 5 | 5 | 5 | 5 | |

| N | 6 | 6 | 6 | 6 | 8 | 8 | 8 | 8 | 10 | 10 | 10 | 10 | 12 | 12 | 12 | 12 | 14 | 14 | 14 | 14 | |

| KG | 5.8 | 6.2 | 6.6 | 7 | 7.4 | 7.8 | 8.2 | 8.5 | 8.9 | 9.3 | 9.7 | 10.1 | 10.5 | 10.9 | 11.2 | 11.6 | 12 | 12.4 | 12.8 | 13.2 | |

|