| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Low Fin Tube |

|---|---|

| Brand Name: | Yuhong |

| Model Number: | ASTM B111 C71500 |

| Certification: | ABS, BV, DNV, CCS, LR |

| Place of Origin: | China |

| Price: | Negotiable |

| Payment Terms: | TT, LC |

| Delivery Time: | 7days |

| Packaging Details: | ply-wooden case/plastic woven bag |

| MOQ: | 100kgs |

| Company Type: | Manufacturer & Exporter |

| Pitch: | 30 FPI /28 FPI/ 26 FPI |

| Packing: | Wooden Case, |

| Materials: | C70600-O61 |

| Fin Material: | Copper |

| Test Before Fining: | Eddy Test , Hydro Test |

| Company Info. |

| YUHONG HOLDING GROUP CO., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

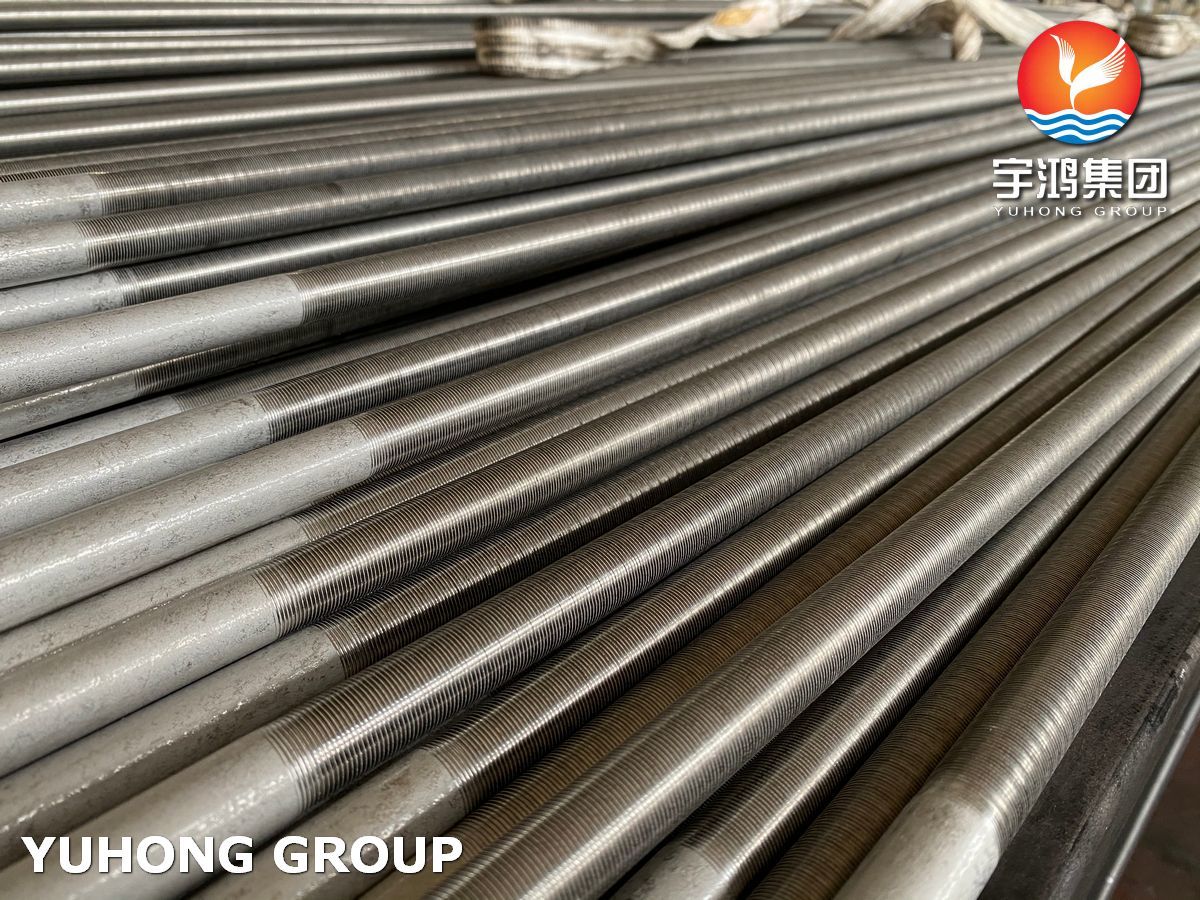

The C71500 Copper Nickel Steel Seamless Low Fin Tube is specifically designed for use in heat exchangers, where efficient heat transfer and corrosion resistance are essential. Made from C71500 copper-nickel alloy, this tube combines excellent corrosion resistance with high thermal conductivity and strength. The low fin design enhances the surface area for heat exchange, making it ideal for use in marine environments, chemical processing, and power generation industries where high-performance heat exchangers are required.

C71500 is a copper-nickel alloy composed of 90% copper and 10% nickel, known for its outstanding corrosion resistance in seawater, chemical environments, and high-temperature systems.

This alloy offers excellent resistance to pitting, stress corrosion cracking, and erosion, making it ideal for use in environments exposed to chlorides and high-temperature fluids like those found in marine applications or heat exchangers in chemical processing plants.

Copper-nickel alloys also offer high thermal conductivity, ensuring efficient heat transfer in industrial heat exchangers and cooling systems.

The low fin design increases the surface area available for heat exchange without significantly increasing the size of the tube, making it ideal for space-constrained heat exchangers.

This design ensures maximum heat transfer efficiency in compact heat exchanger systems, where high-performance heat exchange is required in environments with restricted space.

The C71500 Copper Nickel Steel Seamless Low Fin Tube is widely used in marine heat exchangers, cooling systems, and chemical processing applications.

Its corrosion resistance to seawater and chemically aggressive fluids, combined with its high thermal conductivity, makes it perfect for seawater cooled systems, furnaces, boilers, and condensers in industries like power generation, desalination plants, and petrochemical industries.

| Element | C71500 Copper-Nickel Alloy (Base Tube) |

|---|---|

| Copper (Cu) | 88.0% - 90.0% |

| Nickel (Ni) | 9.0% - 11.0% |

| Iron (Fe) | ≤ 1.0% |

| Manganese (Mn) | ≤ 1.0% |

| Lead (Pb) | ≤ 0.05% |

| Zinc (Zn) | ≤ 1.0% |

| Silicon (Si) | ≤ 0.5% |

| Property | C71500 Copper-Nickel Alloy (Base Tube) |

|---|---|

| Tensile Strength | 485 MPa (min) |

| Yield Strength | 170 MPa (min) |

| Elongation | ≥ 40% |

| Hardness | Brinell hardness: 100 - 150 HB |

Superior Corrosion Resistance:

The C71500 copper-nickel alloy offers outstanding resistance to pitting, crevice corrosion, and stress corrosion cracking, particularly in marine environments and seawater systems. This makes it ideal for cooling systems, marine heat exchangers, and desalination plants.

High Thermal Conductivity:

Copper-nickel alloys provide excellent thermal conductivity, ensuring that the tube performs effectively in heat exchangers and cooling systems by promoting efficient heat transfer.

Durability:

The seamless tube construction with mechanically bonded low fins ensures long-term reliability and performance, even in the harshest industrial applications, such as high-temperature heat exchangers and power generation systems.

Space-Efficient Design:

The low fin design significantly increases the surface area for heat exchange while maintaining a compact form, making it ideal for space-constrained heat exchangers in marine cooling systems and industrial heat exchangers.

Resistant to Seawater and High-Temperature Environments:

The combination of copper and nickel provides superior resistance to seawater corrosion, making this tube particularly effective in marine applications where the tube is exposed to saltwater.

Marine Heat Exchangers: Widely used in seawater-cooled heat exchangers and marine systems, where the tube is exposed to high-temperature fluids and saltwater.

Chemical Processing: Effective in chemical reactors, cooling systems, and desalination plants where corrosion resistance and heat transfer efficiency are essential.

Power Generation: Ideal for power plants and furnaces, where heat must be efficiently transferred from hot gases to the cooling medium.

HVAC Systems: Used in air conditioning, chillers, and industrial refrigeration systems that require efficient cooling with minimal space.

|