| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | BS 3262 |

|---|---|

| Brand Name: | HUA QUN |

| Model Number: | HQ-107 |

| Certification: | ISO9001 |

| Place of Origin: | China |

| MOQ: | 1 ton |

| Price: | Pending |

| Payment Terms: | L/C, Western Union, T/T |

| Supply Ability: | 100 tons per day |

| Delivery Time: | 3-7work days |

| Packaging Details: | 25kg per bag,40 bags per ton,25-27 tons per 1x20ft container |

| Soft Point: | 90~125℃ |

| Gloss Level: | High gloss finish |

| Usage: | stripping marking |

| Other Names: | Thermoplastic Traffic Paint |

| Storage: | Dry Environment |

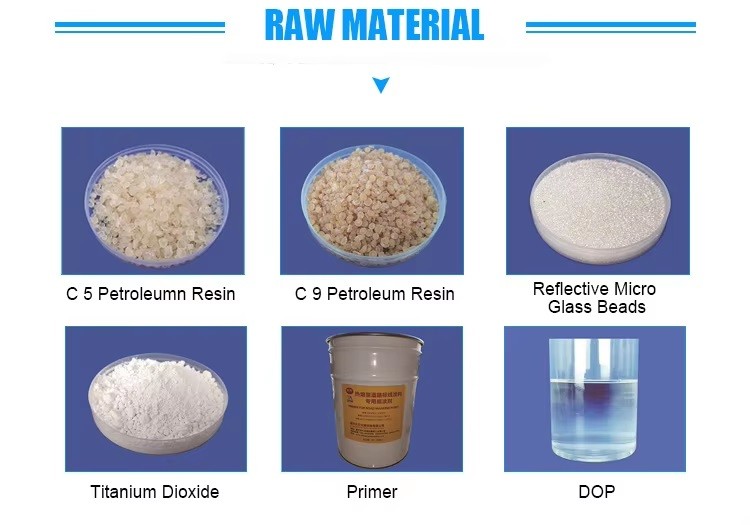

| Material: | petroleum resin |

| Packing: | 25kgs/bag |

| Coating Rate: | About 180-200m2/ton |

| Company Info. |

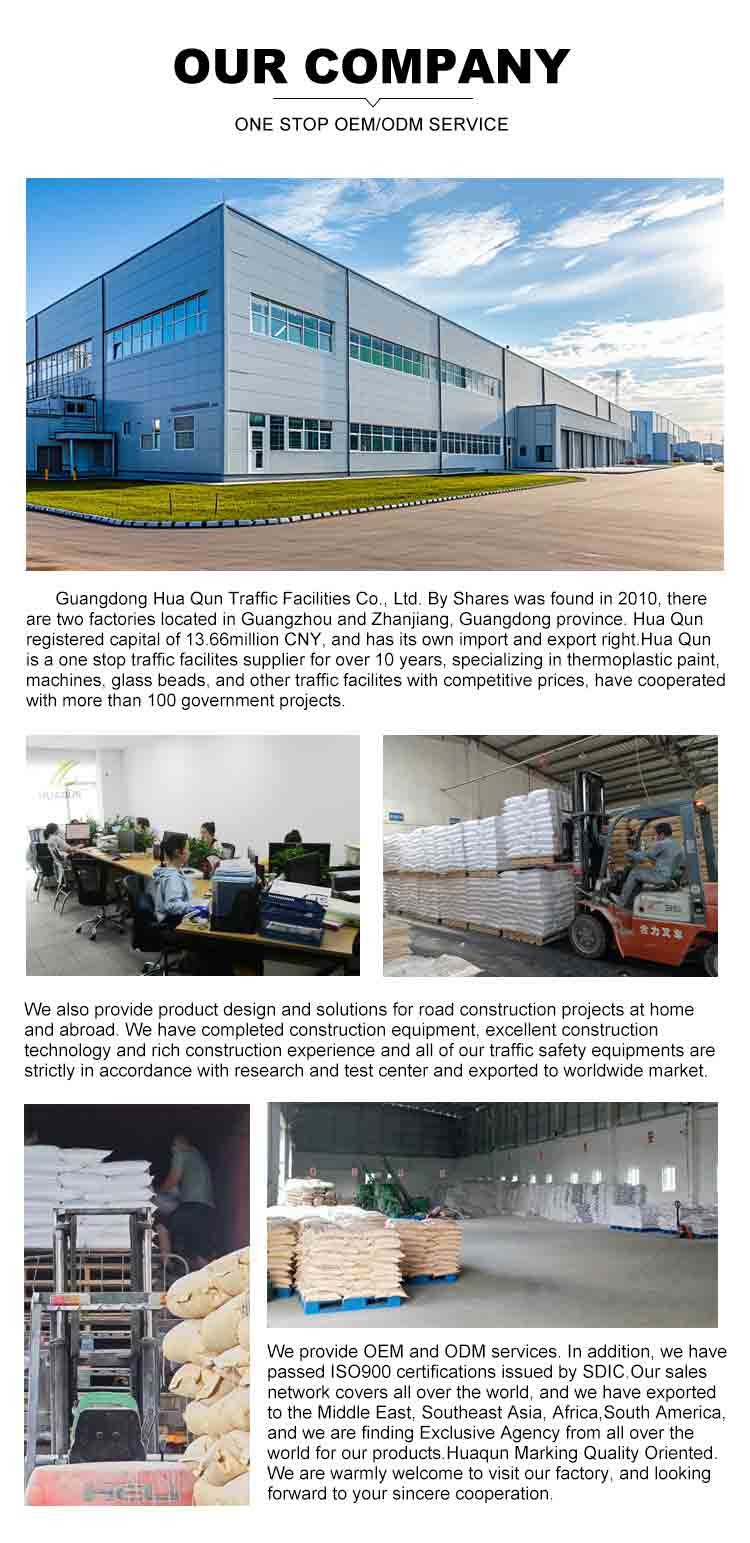

| Guangdong Hua Qun Traffic Facilities Co., Ltd. By Shares |

| Verified Supplier |

| View Contact Details |

| Product List |

Application of Thermoplastic Paint in Road Markings

Thermoplastic paint have emerged as a crucial material in the field of road markings,

offering numerous advantages that contribute to the safety and

efficiency of road transportation systems.

I. Introduction to Thermoplastic Paint for Road Markings

Thermoplastic paint used in road markings are typically composed of resins, pigments,

fillers, and additives. The resins provide the adhesive and

cohesive properties, ensuring the coating adheres firmly to the

road surface and maintains its integrity. Pigments are added to

give the markings their distinct colors, such as white for lane

dividers and yellow for center lines, enhancing visibility. Fillers

improve the durability and mechanical strength of the coating,

while additives may be used to modify properties like drying time

and resistance to weathering.

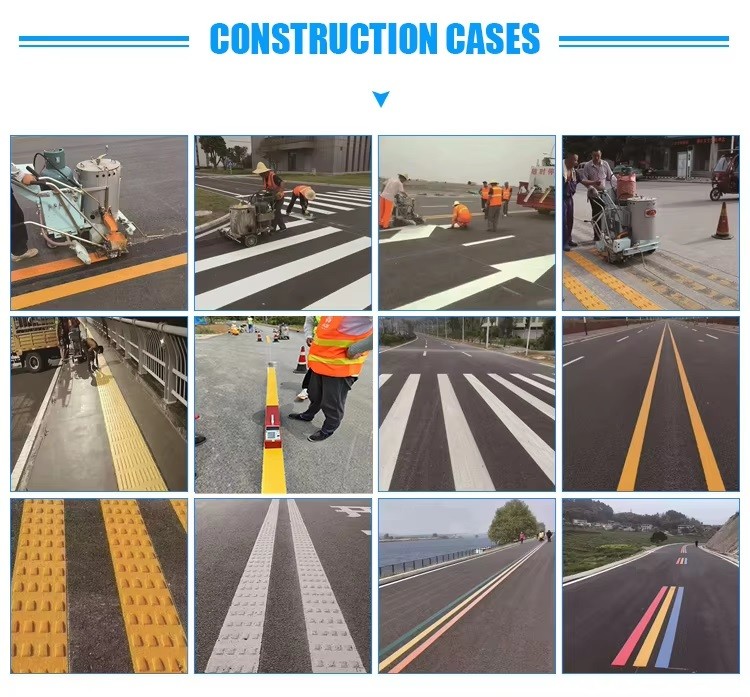

II. Application Process

1. Surface Preparation: Before applying the hot melt coating, the

road surface must be thoroughly cleaned. This involves removing

dirt, debris, oil, and any loose materials. Sweeping, pressure

washing, or using specialized cleaning equipment is common. A dry

and clean surface is essential for proper adhesion of the coating.

2. Melting and Application: The hot melt paint material is heated

in a specialized melting kettle to a specific temperature range,

usually between 180 - 220 degrees Celsius. Once melted, it can be

applied using various methods. One common approach is through a

thermoplastic sprayer or a squeegee. For example, in the case of

spraying, the molten coating is evenly sprayed onto the road

surface in the desired pattern. When using a squeegee, the melted

coating is poured onto the road and then spread evenly to the

required thickness, usually around 1.5 - 3 millimeters for standard

road markings.

3. Drying and Curing: After application, the hot - melt coating

cools and solidifies rapidly. This quick - drying property

minimizes the disruption to traffic flow during the marking

process. Once solidified, the coating forms a durable and hard

layer that can withstand the heavy loads and friction from vehicle

tires.

III. Advantages in Road Markings

1. High Durability: Thermoplastic paints are highly resistant to

wear and abrasion caused by the continuous passage of vehicles.

They can maintain their visibility and integrity for an extended

period, reducing the need for frequent repainting. This durability

is especially important on high - traffic roads and highways.

2. Excellent Visibility: The pigments in hot - melt paint provide

bright and clear colors that are highly visible under various

lighting conditions, including daylight, headlights at night, and

in wet weather. This enhanced visibility helps drivers clearly

identify lanes, crosswalks, and other important road markings,

improving road safety.

3. Adhesion to the Road Surface: The strong adhesion of hot melt

coatings to different types of road surfaces, such as asphalt and

concrete, ensures that the markings stay in place. They are less

likely to peel off or become damaged due to weather changes or the

mechanical stress of traffic.

4. Weather Resistance: These paints are designed to withstand a

wide range of weather conditions, including rain, snow, sunlight,

and temperature variations. They do not fade easily and can

maintain their performance characteristics over time.

IV. Specification

| Density (g/cm3) | 1.8-2.3 |

| Softening point(℃) | 90-125 |

| Compressive strength(MPa) | ≥12 |

| Glass bead content(%) | 0-30%(Customized) |

| Liquidity | 35±10 |

| Packing | 25kg/bag±0.2 |

| Color | White/Yellow/Blue/Green/Customized |

| Executive standard | JT/T280-2004/AASHTO/BS3262/Customized |

| Appearance | Powder |

| Construction temperature | 180℃-220℃ |

| Whiteness | 70-85(Customized) |

| Inverse coefficient | 50-550 |

| Warranty | 365days |

| Storage Method | Avoid light and moisture |

| Packing size | 45×70×5cm |

V. Conclusion

In conclusion, thermoplastic paints have revolutionized road

markings with their unique combination of durability, visibility,

adhesion, and weather resistance. Their proper application ensures

clear and long - lasting road markings, which are vital for the

safe and efficient operation of our road networks. Continued

research and development in this area are expected to further

improve the performance of hot - melt coatings in road

applications, contributing to enhanced road safety for all road

users.

|