| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Flexible Metal Braided Hose |

|---|---|

| Brand Name: | Liang He |

| Model Number: | JTW |

| Certification: | ISO 9001 |

| Place of Origin: | Henan,China |

| MOQ: | 1 piece |

| Price: | $12.3-19.2 per set |

| Payment Terms: | T/T, D/A, D/P, Western Union, MoneyGram, L/C |

| Supply Ability: | 8000 piece per month |

| Delivery Time: | 1-7 day |

| Packaging Details: | cartons,wooden cases |

| Technics: | Casting |

| Warranty: | 1 year |

| Customized support: | OEM, ODM |

| Connection: | Flange |

| Material: | Stainless Steel |

| Application: | Oil Gas Water Industrial |

| Color: | Sliver |

| Size: | Customized Size |

| Surface treatment: | Mirror Polish |

| Company Info. |

| Henan Lianghe Pipeline Equipment Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

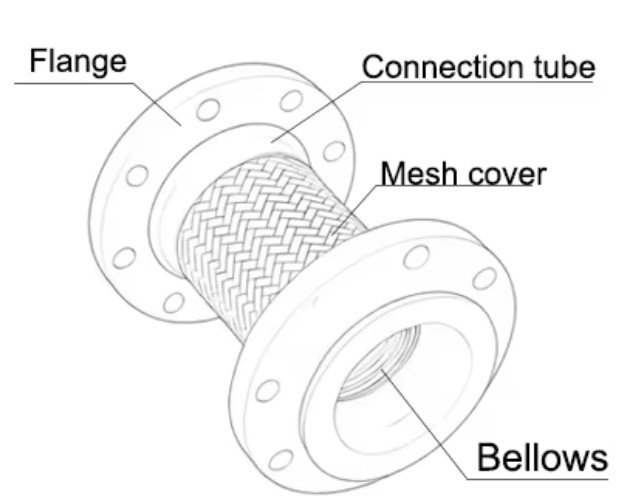

Flanged metal hose product introduction

Flanged metal hose is an industrial connection solution consisting of metal bellows, mesh sleeves and fittings that are highly efficient and versatile. Its main structure includes metal bellows, mesh sleeves and joints, of which metal bellows provide flexibility and corrosion resistance, mesh sleeves enhance protection, and joints are flanged to facilitate docking with various equipment.

Flanged metal hose structure features

1. Metal bellows: It has excellent flexibility and corrosion resistance, and can

maintain stable performance in complex working environments.

2. Mesh sleeve: Reinforces and protects the bellows from deformation when

subjected to external pressure.

3. Joint: Flange Connection is used to achieve fast and reliable connection

and reduce the risk of leakage.

Flanged metal hose application advantages

1. High flexibility: The metal bellows design makes the flanged metal hose easily cope

with various complex pipe layouts and reduces the difficulty of

installation.

2. Strong corrosion resistance: The metal material can resist the erosion of a variety of

chemicals and adapt to various harsh working environments.

3. Stable connection: The flange connection design makes the connection between the hose

and the equipment tighter and more stable, reducing the risk of

leakage.

4. Easy maintenance: Simple structure, relatively easy to maintain and replace, reduce

maintenance costs.

Product parameters

Nominal diameter DN | Inner diameter | Outer diameter | Minimum bending radius | Working pressure | |||

| Bellows | Braid mesh | Static | Dynamic | Single braid mesh | Double braid mesh | ||

| 8 | 8.8 | 13.2 | 14.4 | 50 | 110 | 15 | 20 |

| 10 | 11.7 | 16.5 | 17.7 | 65 | 145 | 185 | 20 |

| 15 | 13.5 | 19.5 | 21.1 | 80 | 180 | 18 | 20 |

| 20 | 20.0 | 27 | 28.6 | 120 | 270 | 10 | 15 |

| 25 | 27.0 | 34.5 | 36.1 | 160 | 360 | 6.3 | 10 |

| 32 | 32.0 | 40 | 41.6 | 175 | 400 | 4.0 | 6.3 |

| 40 | 39.6 | 52 | 53.6 | 225 | 510 | 4.0 | 6.3 |

| 50 | 49.7 | 62 | 63.6 | 280 | 640 | 3.0 | 5.0 |

| 65 | 61.2 | 80.2 | 81.8 | 410 | 915 | 3.0 | 5.0 |

| 80 | 79.0 | 96.3 | 97.9 | 486 | 1030 | 3.0 | 5.0 |

| 100 | 101.2 | 119.6 | 121.2 | 610 | 1340 | 2.5 | 4.0 |

| 125 | 124.1 | 145.3 | 146.9 | 700 | 1540 | 2.5 | 4.0 |

| 150 | 149.4 | 180.8 | 182.4 | 810 | 1780 | 2.5 | 4.0 |

| 200 | 176.0 | 240 | 243.2 | 1000 | 2000 | 2.5 | 4.0 |

| 250 | 248.0 | 290 | 294 | 1250 | 2500 | 2.5 | 4.0 |

| 300 | 298.0 | 350 | 354 | 1500 | 3000 | 1.6 | 2.5 |

| 350 | 347.0 | 400 | 404.8 | 1750 | 3500 | 1.6 | 2.5 |

| 400 | 397.6 | 460 | 464.8 | 2000 | 4000 | 1.6 | 2.5 |

Product Types of Metal Flexible Hose

Flange Metal Hose( Movable flange ) Flange Metal Hose( Fixed flange )

PTFE Lined Metal Hose Threaded Metal Hose

Flanged metal hose usage scenario

Flanged metal hoses are widely used in many industries, including petrochemical, pharmaceutical, food processing, etc. In the petrochemical industry, where conventional rubber hoses are not sufficient due to their ability to handle large quantities of corrosive substances, flanged metal hoses are up to the challenge. In the pharmaceutical and food processing sectors, it is the first choice in these industries due to its corrosion resistance and ease of cleaning.

Precautions for the use of flanged metal hoses

1. The bellows of the stainless steel hose is made of

chromium-nickel austenitic stainless steel, and attention should be

paid to prevent the pitting corrosion of nitrogen ions and dilute

sulfuric acid, and the corrosive damage of dilute sulfuric acid.

2. After the user conducts the hydraulic test on the equipment and

pipe system equipped with stainless steel hoses, it should prevent

the impact of rust blocks and the deposition of chloride-containing

sediment, which will cause corrosion and mechanical damage.

3. When installing, the metal hose should be prevented from spatter

scalding and mechanical damage during welding, otherwise it will

cause leakage.

4. The sealing pipe system should strictly abide by the safety

operation procedures to prevent the hose from being pulled off or

burst due to overpressure caused by improper operation or other

factors.

5. Please carefully digest the example of stainless steel hose

installation method, and install and use it in strict accordance

with the correct sketch.

Product Applications

FAQ

Q: Can the products be manufactuered by customer's requirement?

A: Yes, the specifications stated above are the standard ones, we can design and manufacture as requirement.

Q: What are your payment terms?

A: T/T (30% as deposit, the rest 70% will be paid before delivery), L/C at sight.

Q: Where is your nearest loading port?

A: Shanghai, Qingdao or Tianjin, China.

Q: Can I visit your factory before the order?

A: Yes, welcome to our factory to check the quality.

Q: And what is your shipment and delivery time?

A: By sea or air. Normally 7 to 14 Days for delivery, according to your order quantity.

|