| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Milling Machine |

|---|---|

| Brand Name: | Luyoung |

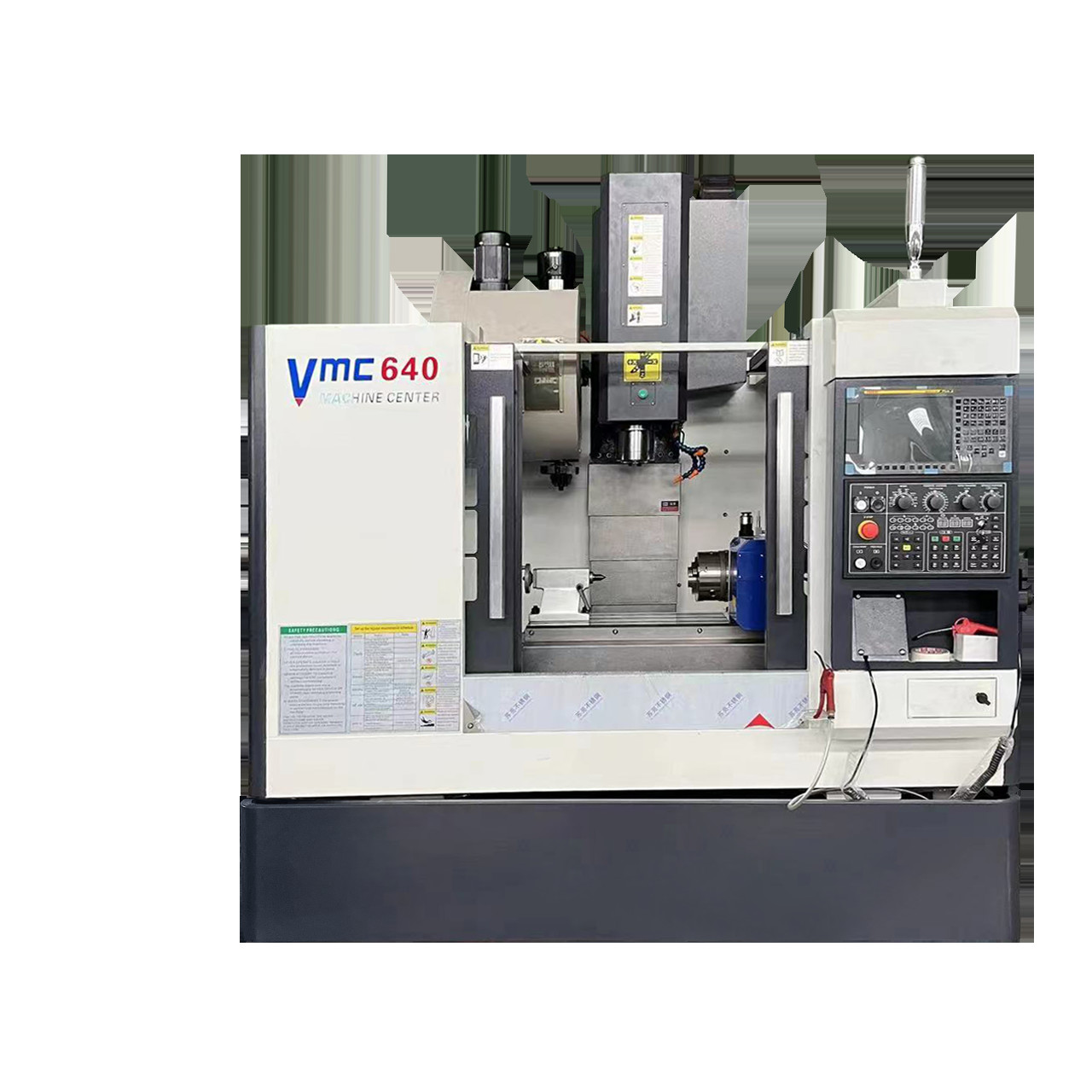

| Model Number: | VMC640 |

| Certification: | CE |

| Place of Origin: | China |

| MOQ: | 1 |

| Price: | USD25000- USD43900 |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100sets |

| Delivery Time: | 45 working days |

| Packaging Details: | Fumigation-free plywood |

| Prouduct Name: | Vertical Milling Machining Center |

| Control System: | CNC |

| Power Supply: | 220V/380V, 3-phase |

| Size: | 900*400 ( mm ) |

| Machine Name: | CNC Milling Machine |

| Year: | 2024 |

| Milling Cutter Structure: | Integral |

| Power: | 5.5/7.5kw |

| Cnc Controller: | FANUC or SIEMENS or GSK |

| Cross Travel: | 450mm |

| Usage: | Processing Machine |

| Spindle speed: | 8000rpm |

| Spindle taper: | Bt40 |

| ATC: | 16 |

| Company Info. |

| shandong lu young machinery co.,ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

VMC640 4 axis BT40 8000rpm spindle bore GSK/Siemens/Fanuc control system vertical machining center

Specifications:

| Work bench | Area of work table | 900×400mm |

| Load capacity | 500 kg | |

| Working mesa from the ground | 120-670 mm | |

| spindle | Motor power | 5.5kw(servo) |

| Distance between the spindle end and the work surface | 120-670 mm | |

| Spindle center to column guide rail | 460 mm | |

| Speed | 8000/10000 rpm | |

| Taper of spindle | BT40 | |

| Distance of travel | X-Axis | 600 mm |

| Y-Axis | 450 mm | |

| Z-Axis | 500mm | |

| Feed | X-axis fast moving | 24m |

| Y-axis fast moving | 24m | |

| Z-axis fast moving | 24m | |

| fast cutting speed mm /min | 16 mm/min | |

| precision | Positional accuracy | 0.01 mm |

| Repeat positional accuracy | 0.005mm | |

| Tools | Max,diameter | 120 mm |

| Max,length | 200 mm | |

| Tool magazine capacity | 16 | |

| Qty time of tool changings | 7 s | |

| Power Supply | Voltage(V)/frequency (Hz) | 380/20 |

| Total capacity(KVA) | 10 | |

| Others | Air pressure | 0.6 Mpa |

| Weight | 4000 kg | |

| Diamention | 2350×2150×2300 mm |

| Standard configuration:vmc640 China 4 axis metal vertical cnc milling machine with factory price | |

| High strength resin sand casting | Imported bearings for lead -srew; HIWIN/NSK |

| X, Y, Z rails adopt stainless steel telescopic cover | Eelectric cabinet cold heat exchanger |

| Standard with belt driven Taiwan spindle---8000RPM | Full enclosed cover |

| GSK25I controller system | Manual pulse generator (MPG) |

| 16 tools type Taiwan ATC | Toolbox |

| Centralized automatic feed lubrication system | 3 Axis lubrication oil collection |

| Air clean gun | Color display |

| Chip storage tank | Foundation pad iron and adjusting bolt |

| Three color warning lamp | USB and Internet interface |

| Cooling system | Leveling blocks & bolts; |

| Work lamp | Rigid tapping |

| Spindle center air blast | |

| Optional configuration:vmc640 China 4 axis metal vertical cnc milling machine with factory price | |

| Taiwan ATC, disc type ---24 | 4th /5th axis |

| Siemens or Fanuc controller system | Chip conveyor outside machine |

| 3 axis Hiwin linear guide way | Tool measure system |

| Workpiece measure system | |

| Main purchase parts brand (vmc640 China 4 axis metal vertical cnc milling machine with factory price) | |

| Name | Brand |

| Spindle Unit | Taiwan |

| Servo Motor | SIEMENS/GSK/FANUC |

| pressure cylinder | Taiwan SUNRISE |

| Screw bearing | FAG |

| Coupling | (R+W) |

| CNC Controller | SIEMENS/GSK/FANUC |

Functions:

Many four-axis machining centers are equipped with an automatic tool change function, enabling quick switching between different tools during the machining process, further enhancing flexibility and efficiency.In summary, four-axis machining centers offer significant advantages in improving machining efficiency, precision, and simplifying processes, making them indispensable equipment in modern manufacturing

Optional configuration:

1. Bridge type 4th axis and 3/5 axis

2.10000rpm or 12000rpm spindle speed

3.Chain type chip conveyor

|