| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | 13X Molecular Sieve Desiccant |

|---|---|

| Brand Name: | Xi'an Lvneng |

| Model Number: | 13X Molecular Sieve |

| Certification: | ISO9001:2008 |

| Place of Origin: | Shaanxi,China |

| MOQ: | 10 Kilograms |

| Price: | Negotiable |

| Supply Ability: | 50 Tons/ per Month |

| Delivery Time: | 3-15 work days |

| Packaging Details: | 1. Carton Drum/25KG 2. Carton Box/25KG; 3. Iron Drum/150KG |

| Payment Terms: | L/C, T/T |

| Model number: | zeolite 13x |

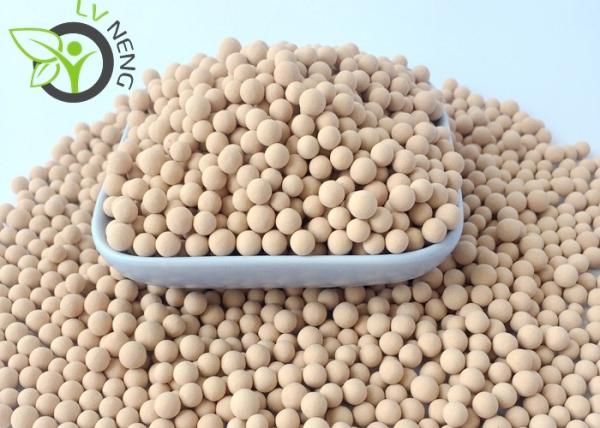

| Shape: | particle |

| Color: | beige |

| Size: | 1.6-2.5mm, 3.0-5.0mm |

| Bulk density: | ≥0.72g/ml, 0.68g/ml |

| Water adsorption: | ≥27.0% |

| Company Info. |

| Xi'an Lvneng Purification Technology Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

13x Molecular Sieve Desiccant Chemical Industrial Gas Dehydration Unit

Overview

Xi’an lvneng 13X Molecular Sieve is the sodium form of the type X crystal and has a much larger pore opening than the type A crystals.It has the highest theoretical capacity of the common adsorbents and very good mass transfer rates.

Molecular Formula

| Molecular Formula | Na2O·Al2O3·(2.8±0.2)SiO2 ·(6-7)H2O |

| SiO2/ Al2O3 | ≈ 2.6-3.6 |

| Normal Pore Opening | 10 Angstroms |

| Shape | Bead |

| Advantages | Big water capacity, high crush strength, low attrition, long service time |

Technical Index

| Molecular Sieve 13X Typical Physical Properties | ||||

| Items | Unit | 8*12 Mesh | 4*6 Mesh | |

| Bead Size | mm | 1.6-2.5 | 3.0-5.0 | |

| Bulk Density | g/ml ≥ | 0.68-0.85 | 0.65-0.80 | |

| Equilibrium Water Capacity @ 25℃ | wt% ≥ | 24.0-27.0 | 24.0-27.0 | |

| Equilibrium Carbon Dioxide Capacity | wt% ≥ | 18 | 18 | |

| Heat of Adsorption | BTU/lb of H2O | 1800 | 1800 | |

| Crush Strength | Point Contact | N ≥ | 30-80 | 80-130 |

| Variation Coefficient | - | 0.3 | 0.3 | |

| Attrition Rate | wt% ≤ | 0.1 | 0.1 | |

| Size Qualification | % ≥ | 97 | 97 | |

| Package Moisture | wt% ≤ | 1.5 | 1.5 | |

| The interval value of the indexes above are on the basis of the different grade of Molecular Sieve 13X | ||||

Typical Application

1.Water, dioxide, hydrocarbons removal

2. General industrial gases drying

3.Gas purification in air separation process

4.Natural gas, liquefied petroleum, liquid hydrocarbons(propane, butane…) dehydration

5.Sulfur dioxide and mercaptan removal

6. General gas (such as compressed air, permanent gas) deeply drying

7.Ammonia synthesis gas drying and purification

8.Aerosol propellant desulfurization and deodorization

9.Carbon dioxide removal from cracked gas

10.Removal of water and carbon dioxide in PSA oxygen generation system

Attention

zeolite 3.0-5.0mm molecular sieve 13x can’t be exposed in the open

air and should be stored in dry condition with the air-proof

package.

zeolite 3.0-5.0mm molecular sieve 13x can be regenerated after a

certain period of adsorption.

The appropriate regenerated temperature would be better below 350°C.

|