| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ultrasonic Spray Coating Machine |

|---|---|

| Brand Name: | FUNSONIC |

| Model Number: | FSLAB01 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 UNIT |

| Price: | Negotation |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1000 unit per month |

| Packaging Details: | Packed by Wooden Case |

| Production Name: | Ultrasonic Dispersion Manual Liquid Supply Pump |

| Applicable syringe types: | 0.5μm-150ml (ultrasonic dispersion of 25, 50, 100ml) |

| Syringe selection: | Built in syringe model and custom syringe inner diameter |

| Linear speed range: | 1μm/min-132mm/min |

| Linear thrust range: | 8-20 kgf, adjustable online |

| Travel resolution: | 0.078μm/μstep |

| Travel control accuracy: | Error ≤ ± 0.3% |

| Display method: | 4.3 inch industrial grade - LCD screen |

| Company Info. |

| Hangzhou Qianrong Automation Equipment Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

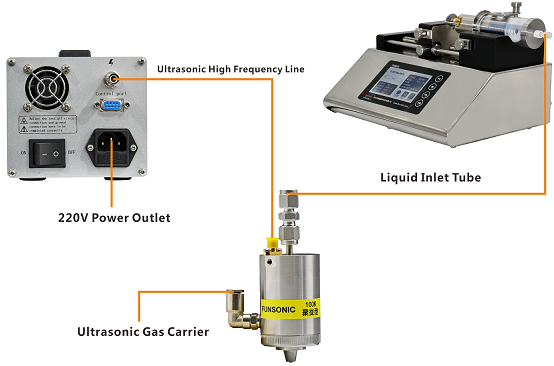

Intelligent Ultrasonic Dispersion Manual Liquid Supply Pump 40Khz

for Ultrasound Spraying System

Description:

Ultrasonic dispersion is achieved by embedding high-frequency

ultrasonic transducers into micro containers (such as sample

injectors/syringes), which can effectively disperse and transport

various nano suspensions, thereby uniformly dispersing nanoscale

and submicron particles and transporting liquids. Sedimentation and

clumping can be avoided during the transportation and spraying of

suspensions. Nanoparticle dispersion systems can be installed in

various injection pumps and are often used as auxiliary accessories

in precision spraying systems. High performance non-contact

acoustic cavitation treatment can be achieved, and samples such as

blood, saliva, and suspended particles can be effectively mixed,

dispersed, and crushed through an ultrasonic dispersion system.

Parameters:

| Item No | Ultrasonic Dispersion Manual Liquid Supply Pump |

| Working mode | Perfusion, extraction, infusion followed by extraction, extraction followed by infusion, continuous mode |

| Number of channels | Optional |

| Applicable syringe types | 0.5μm-150ml (ultrasonic dispersion of 25, 50, 100ml) |

| Syringe selection | Built in syringe model and custom syringe inner diameter |

| Linear speed range | 1μm/min-132mm/min |

| Linear speed adjustment resolution | 1μm/min |

| Linear thrust range | 8-20 kgf, adjustable online |

| Maximum stroke | 140mm |

| Travel resolution | 0.078μm/μstep |

| Travel control accuracy | Error ≤ ± 0.3% |

| Fallback distance | 0.01-10mm |

| Common modes | Can save 60 sets of common modes |

| Display method | 4.3 inch industrial grade - LCD screen |

| Operation method | Touch screen+buttons |

| State output | OC gate signal output, used to indicate operating status and direction |

| communication interface | RS232/RS485 (Modbus protocol, RTU mode) |

| Universal power supply | AC100-240V/65W |

| Protection level | IP31 |

| Product size (mm) | 280*210*140 |

| Product weight (kg) | 5.3 |

Advantages:

1. Compared to some traditional dispersion methods, ultrasonic

dispersion is an effective dispersion method that is less costly

and easy to operate and maintain.

2. Ultrasonic dispersion syringe, which enables the solution to be

ultrasonically dispersed before atomized spraying, avoids the

precipitation of solids during the spraying process.

Ultrasonic dispersion systems transform liquids into a dispersion

state, i.e. fine or ultra-fine ultrasonic grinding of solids or

fluids due to the ultrasonic vibration effect. Grinding solid

particles suspended in liquids or simply destroying solid and

viscous substances of the metal or stone type immersed in liquids

requires a modality, since the destruction of strong substances

requires shock waves due to the rupture of cavitation bubbles. And

due to the specificity of the ultrasonic field generated in liquid

media, ultrasonic dispersion provides highly dispersed,

homogeneous, chemically pure suspensions (particle size less than 1

μm).

Intelligent Ultrasonic Dispersion Manual Liquid Supply Pump 40Khz

for Ultrasound Spraying System

|