| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ultrasonic Spray Coating Machine |

|---|---|

| Brand Name: | FUNSONIC |

| Model Number: | FS650 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 UNIT |

| Price: | Negotation |

| Payment Terms: | T/T, Western Union |

| Supply Ability: | 1000 unit per month |

| Packaging Details: | Packed by Wooden Case |

| Production Name: | Production Ultrasonic Spraying System |

| Frequency: | 20-200khz for selection |

| Max Power: | 100w |

| Continuous Spraying Volume Max: | 20-1200ml/h/pcs,Scalable |

| Effective Spraying Width: | 2-260mm/pcs,Scalable |

| Spray Uniformity: | <5% |

| Solution Viscosity: | ≤30cps |

| Input Voltage: | 220V±10%/50-60Hz |

| Company Info. |

| Hangzhou Qianrong Automation Equipment Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Industrial Ultrasonic Spray Coating Servo Motion System Benchtop for Thin Film Coated

Description:

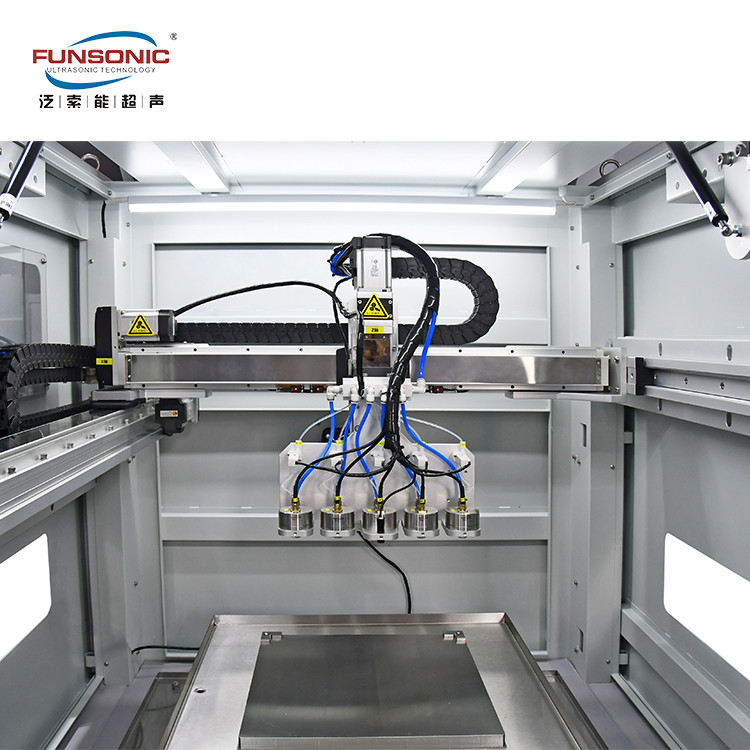

The FUNSONIC floor standing ultrasonic precision spraying machine FS650 is mainly used for medium scale production and large-area film production. The entire equipment has a simple and elegant structure, with complete functions, mainly including the XYZ three-axis servo motion system and the R-axis nozzle rotation mechanism. It is equipped with FUNSONIC's independently developed ultrasonic spraying special control system, achieving a comprehensive trajectory editing system with matching functions and spraying functions for any two-dimensional plane shape.

Parameters:

| Product Type | Ultrasonic Precision Spray Coating Machine Laboratory desktop Type FS310 | Intelligent Ultrasonic Precision Coating Machine desktop Type FS620 | Benchtop Ultrasonic Spray Coating Machine FS650 |

| Spray Nozzle Operating Frequency | 20-200KHz | 20-200KHz (Normally use 60100110120K) | 20-200KHz (Normally use 60100K) |

| Nozzle Power | 1-15W | 1-15W | 1-15W |

| Continuous Spraying Volume Max | 0.01-50ml/min | 0.01-50ml/min | Determine based on the type and quantity of nozzles configured (Max 5 Nozzles) |

| Effective Spraying Width | 2-100mm | 2-100mm | Determine based on the type and quantity of nozzles configured |

| Spray Uniformity | ≥95% | ≥95% | ≥95% |

| Solution Conversion Rate | ≥95% | ≥95% | ≥95% |

| Dry Film Thickness | 20nm-100μm | 20nm-100μm | 20nm-100μm |

| Solution Viscosity | ≤30cps | ≤30cps | ≤30cps |

| Temperature Range | 1-60℃ | 1-60℃ | 1-60℃ |

| Atomized Particles (Median Value) | 10-45μm (distilled water), determined by the frequency of the nozzle | 10-45μm (distilled water), determined by the frequency of the nozzle | 10-45μm (distilled water), determined by the frequency of the nozzle |

| Diversion Pressure Max | ≤0.10MPA | ≤0.15MPA | ≤0.15MPA |

| Input Voltage | 220V±10%/50-60Hz | 220V±10%/50-60Hz | 220V±10%/50-60Hz |

| Exercise Mode | X+Y two axis fully automatic, Z-axis manual adjustment | XYZ three-axis, independently programmable | A spraying control system independently developed by FUNSONIC based on the Windows system, with PLC control, 15.6-inch full-color touch screen, XYZ three-axis imported servo motor, R-axis start rotation, and fully enclosed precision screw module |

| Control Mode | Micro computer card, 7-inch touch screen+buttons | FUNSONIC spraying control system, PLC control, 13.3-inch full-color touch screen | PLC control, operation control system developed based on Windows system, supporting remote operation, upgrading, etc |

| Control Content | Ultrasonic spraying, liquid supply, heating, ultrasonic dispersion and other systems | Ultrasonic spraying, liquid supply, heating, ultrasonic dispersion and other systems | The touch screen integrates ultrasonic nozzle, liquid supply, heating, adsorption, ultrasonic dispersion and other controls, and also has system monitoring, alarm and other functions |

| Liquid Supply Method | Precision injection pump | Precision injection pump | Precision injection pump |

| Ultrasonic Dispersion System (Optional) | 50ml, 40K, biological grade sampler | 20ml or 50ml, 40K, biological grade sampler | 20ml or 50ml, 40K, biological grade sampler |

The influencing factors of ultrasonic spraying:

1. Droplet size: The frequency of ultrasonic spraying equipment affects the size of droplets, and the higher the frequency, the smaller the droplet size. The median droplet size at 20Khz and 20kHz is 90 microns, and at 40kHz, the droplet size further decreases to an average of 45 microns.

2. Success or failure of atomization: If the ultrasonic energy is too high, cavitation will occur. The excessive energy will not form an ideal thin film at the top of the nozzle, causing the liquid flowing through the nozzle to atomize prematurely and "tear" into droplets of different sizes. Only the amplitude generated at a specific power can produce a relatively ideal atomization effect. For ultrasonic atomization spraying, the input power level is generally around 10 to 15 watts.

3. Atomization flow rate: The flow rate range of ultrasonic atomization nozzles is generally relatively large, unlike traditional air driven nozzles that rely on the power of air to decompose the liquid flow for atomization. Therefore, the amount of liquid atomized by the nozzle per unit time of the same solution is mainly controlled by the liquid conveying system used in combination with the atomizing nozzle.

Industrial Ultrasonic Spray Coating Servo Motion System Benchtop for Thin Film Coated

|