| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Multi Enzyme |

|---|---|

| Brand Name: | BESTHWAY |

| Model Number: | BXW-21 |

| Certification: | ISO9001,ISO22000 |

| Place of Origin: | China |

| MOQ: | 100KG |

| Payment Terms: | T/T, D/P, D/A, L/C |

| Supply Ability: | 100T/month |

| Delivery Time: | 10-15work days |

| Packaging Details: | Solid Product: 25kg/bag Liquid Product: 30L/barrel. |

| Type: | Powder/Liquid |

| Main Enzymes: | Lipase, Phospholipase, Hemicellulase |

| pH Range: | 6.0-9.0 |

| Temperature Range: | 30℃-65℃ |

| Company Info. |

| Jintang Bestway Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Waste Paper Adhesive Control Enzyme

Besthway Waste Paper Adhesive Control Enzyme is developed by Besthway Technology with modern genetic engineering, microbe fermentation and advanced post-process technology. It can make the adhesive component break, directly lose viscosity, no longer polymerization, and can substantially adsorb the fine adhesive to the negatively charged fibers, and can improve the water filtration performance of the paper machine when copying.

| Item | Specification |

| Type | Powder and Liquid |

| Main Enzymes | Lipase, Phospholipase, Hemicellulase |

| pH Range | 6.0-9.0 |

| Temperature Range | 30℃-65℃ |

Product Functions

Application Scheme

Package and Storage

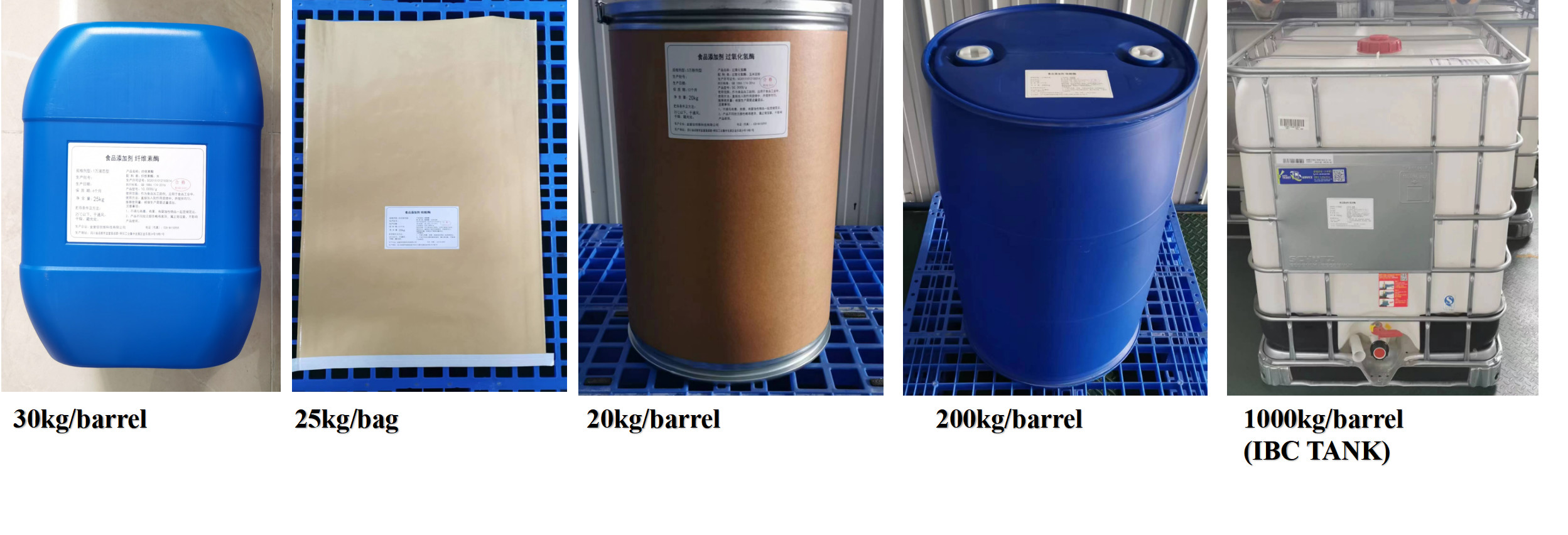

Solid Product: 25kg/bag Liquid Product: 30L/barrel.

It should be stored under dry, ventilated and protected from light at 25℃, with a shelf life of 18 months for solid product and 12 months for liquid product from the date of production. The shelf life could be extended when refrigerated at 5℃.

Note

|