| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Multi Enzyme |

|---|---|

| Brand Name: | BESTHWAY |

| Model Number: | BXW-10 |

| Certification: | ISO9001,ISO22000 |

| Place of Origin: | China |

| MOQ: | 100KG |

| Payment Terms: | T/T, D/P, D/A, L/C |

| Supply Ability: | 100T/month |

| Delivery Time: | 10-15work days |

| Packaging Details: | Solid Product: 25kg/bag Liquid Product: 30L/barrel. |

| Type: | Powder/Liquid |

| Main Enzymes: | Cellulase and Hemicellulase |

| pH Range: | 5.5-9.5 |

| Temperature Range: | 30℃-65℃ |

| Company Info. |

| Jintang Bestway Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Mechanical Pulp Specialized Enzyme,Complex Enzyme,Reduces The Hardness Of The Final Paper

Mechanical Pulp Specialized Enzyme

Besthway Mechanical Pulp Specialized Enzyme is developed by Besthway Technology with modern genetic engineering, microbe fermentation and advanced post-process technology. It can make the fiber break through the wall to achieve sufficient water absorption and wetting, as well as filamentation broom, so that the fiber becomes soft, increased strength, and can be broken between the fiber and lignin viscous material, so that the lignin can be separated, and the hardness of the finished paper is reduced, and, at the same time, the pulp copying performance is better.

| Item | Specification |

| Type | Powder and Liquid |

| Main Enzymes | Cellulase and Hemicellulase |

| pH Range | 5.5-9.5 |

| Temperature Range | 30℃-65℃ |

Product Functions

Application Scheme

Package and Storage

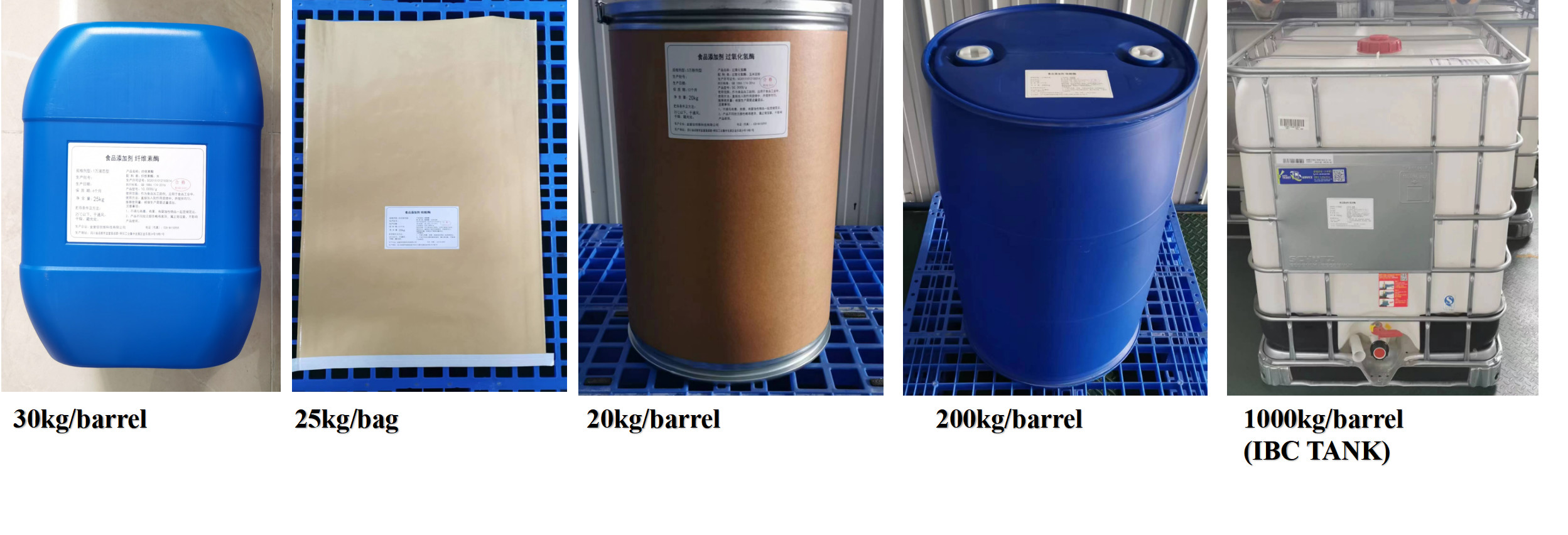

Solid Product: 25kg/bag Liquid Product: 30L/barrel.

It should be stored under dry, ventilated and protected from light at 25℃, with a shelf life of 18 months for solid product and 12 months for liquid product from the date of production. The shelf life could be extended when refrigerated at 5℃.

Note

|