| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Nickel Alloy Forging Ring |

|---|---|

| Brand Name: | DINGSCO |

| Model Number: | According to customers' requirements |

| Certification: | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | Negotiable |

| Delivery Time: | (Sample order) 7 days |

| Packaging Details: | According to customers' requests |

| Product Name: | Heat Treatment Nickel Alloy |

| Material: | Nickel Alloy |

| Size: | Customized |

| Grade: | Inconel,Monel,Incoloy,Hastelloy,Duplex |

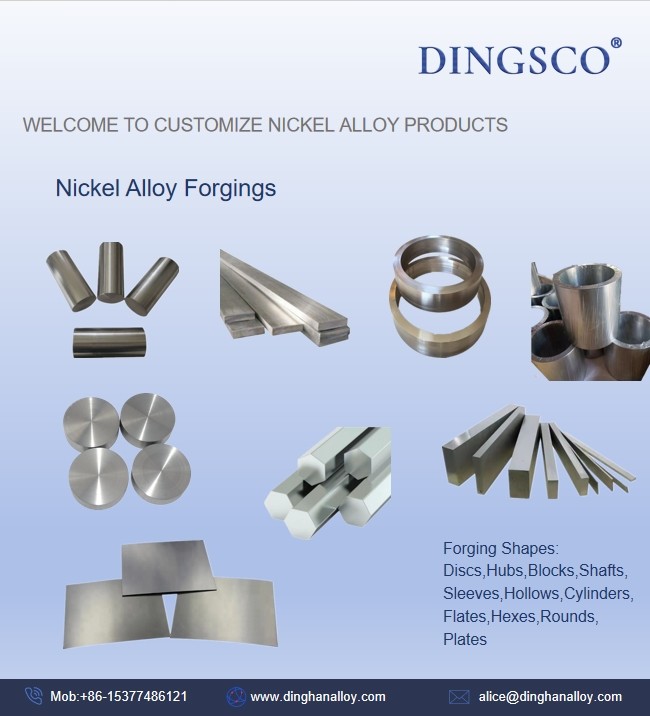

| Shape: | Ring |

| Application: | Oil & Gas,Aerospace, Chemical Processing, Petrochemical, Power Generation, |

| Company Info. |

| Hunan Dinghan New Material Technology Co., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

Heat Treatment Nickel Alloy Forged Ring Incoloy 825/925/800 in Nuclear Industrial

| Grade | UNS | Density | Tensile Strength (MPa min) | Yield Strength (MPa min) | Reduction of Area min (%) | Elongation min (%) | Hardness (HRC) |

| INCOLOY 825 | N08825 | 8.14 | 586MPa min | 241MPa min | / | 30% min | HRC35 max |

| INCOLOY 925 | N09925 | 8.08 | 965MPa min | 724MPa min | 25% | 18% min | HRC38 max |

| INCOLOY 800 | N08800 | 7.94 | 448MPa min | 172MPa min | / | 30% min | HRC35 max |

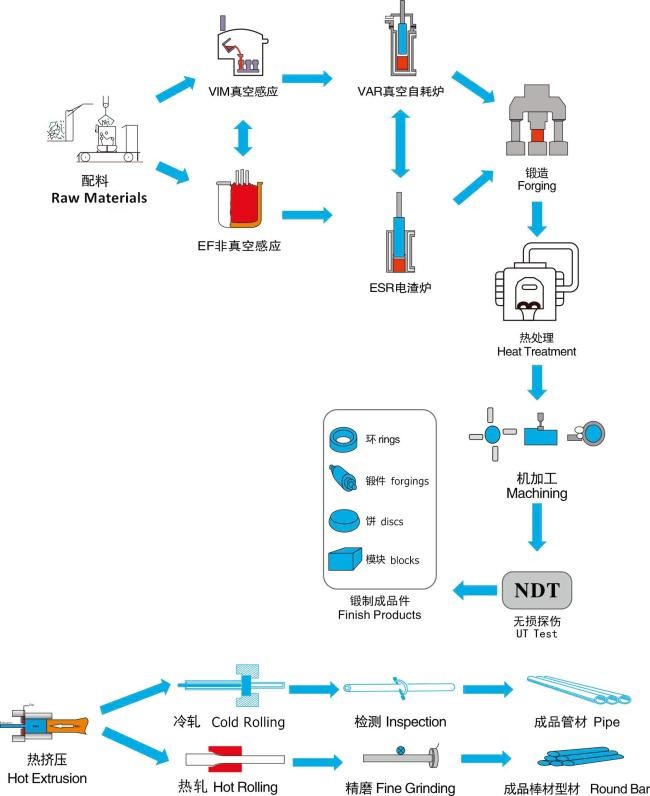

Production Process:

|