| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Nickel Alloy Forging Ring |

|---|---|

| Brand Name: | DINGSCO |

| Model Number: | According to customers requirements |

| Certification: | ISO 9001:2015,PED 2014/68/EU,API 6A,API-20B,TSG,NORSOK |

| Place of Origin: | China |

| MOQ: | Negotiable |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | Negotiable |

| Delivery Time: | (Sample Order) 7 days |

| Packaging Details: | According to Customers' Requests |

| Product Name: | Nickle Alloy Forging Ring |

| Grade: | Monel Alloy 400 |

| UNS: | NO4400 |

| Density: | 8.8 g/cm³ |

| Melting Point: | 1300℃–1350°C |

| Rigidity Coefficient: | 65.3kN/mm² |

| Company Info. |

| Hunan Dinghan New Material Technology Co., LTD |

| Verified Supplier |

| View Contact Details |

| Product List |

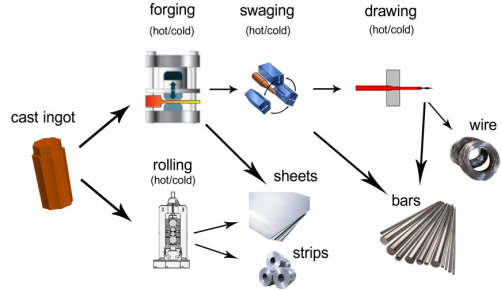

Nickle Alloy Ring are the most common in forged metals. Through open die forging,the metal is formed into something that's shaped like a doughnubefore it's heated between 400 and 700'c. Next, it's placed on a mandrel or idler rol that increases the steel ring's diameters and reduces thethickness of its walls. You can find them in machinery and equipment, vehicles, pipes and valves, and other hardware. Almost all vehicles and otherheavy machinery make use of them because they are durable and easy to replace and look for.

Monel 400 (UNS NO4400/W.Nr. 2.4360) is a nickel-copper alloy (about 67% Ni- 23% Cu) that is resistant to sea water and steam at high temperatures aswel as to salt and caustic solutions. Aloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloyexhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowingbrackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to avariety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions

Chemical Composition:

| Element | C | Si | Mn | S | Cu | Fe | Ni+Co | Co |

| Minimum(%) | - | - | - | - | 28 | - | 63 | - |

| Max(%) | 0.3 | 0.5 | 2 | 0.024 | 34 | 2.5 | 70 | 2 |

Nature:

| State | Approximate tensile strength (N/mm²) | Approximate Operating Temperature(°C) |

| Annealing | 400-600 | -200 to +230 |

| Elastic tempering | 800-1100 | -200 to +230 |

Our QC Activities and Test Methods:

| Chemical Analysis | ASTM E1473ensile | Test | ASTM E8 |

| Hardness Test | ASTM E 10,E 18 | PMl Examination | DINGSCO SOP |

| Ultrasonic NDT | BS EN 10228 | Liquid Penetrant NDT | ASTM E 165 |

| Dimensional and inspection | DINGSCO SOP | Roughness Test | DINGSCO SOP |

| Impact Test | ASTM E 23 | Low Temperature lmpact Test | ASTM E 23 |

| Creep and Stress Rupture Test | ASTM E 139 | Hydrogen Induced Cracking Test | NACE TM-0284 * |

| Inter Granular Corrosion Test | ASTM A 262 * | Sulfide Stress Corrosion Cracking Test | NACE TM-0177 * |

| Pitting and Crevice Corrosion Test | ASTM G 48 * | Macro Etching Test | ASTM E 340* |

| Grain Size Test | ASTM E 112 * |

* Done by state own third party laboratory

Processing Flow Chart:

|