| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Ampoule Filling Machine |

|---|---|

| Model Number: | LYAPL1-20-I |

| Certification: | CE, ISO, GMP |

| Place of Origin: | China |

| MOQ: | 1 unit |

| Price: | USD 150,000-350,000 per unit |

| Payment Terms: | D/A,D/P,T/T,Western Union,MoneyGram |

| Supply Ability: | 1 unit per month |

| Delivery Time: | 180 work days |

| Packaging Details: | carton, wood carton, pallets |

| Machine Name: | Ampoule Filler |

| Function: | Ampoule Washing, Sterilization, Filling, Sealing |

| Filling Volume: | 1-20ml |

| Filling Liquid Type: | Clinic Scale Liquid Solution |

| Max Output Capacity: | 22000 BPH |

| Ampoules Material: | Glass |

| Filling Accuracy: | +/-0.5% |

| Breakage Rate: | <0.5% |

| CIP/SIP System: | Available |

| Oven Sterilization Style: | Dry Heating |

| Nitrogen Flushing: | Before and after filling |

| Sealing Style: | Wire Sealing |

| LAF System: | ISO Class A |

| Material Compatibility: | SS316 |

| After-sales Service & Technical Support: | 1-2 years guarantee maintenance, free spare parts available, and troubleshooting assistance to minimize downtime |

| Company Info. |

| Suzhou Lingyao Intelligent Equipment Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Compact Ampoule Filler for Clinic-Scale Production 22000BPH CE cert GMP standard

The advantages of having Compact Ampoule Filler in the bottle washing machine for ampoules are as follows:

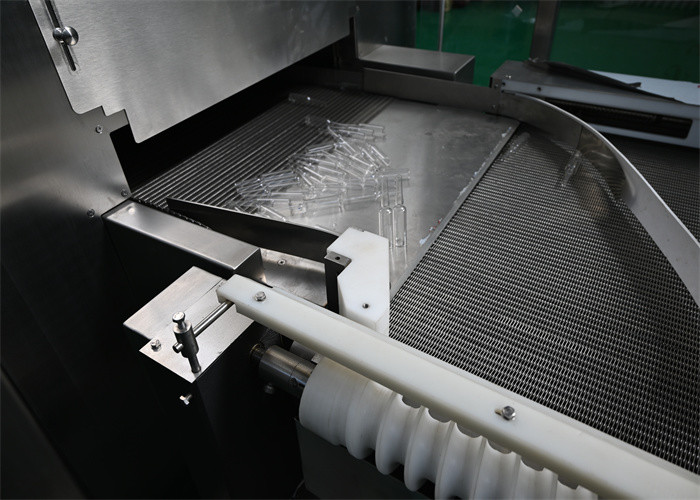

The Compact Ampoule Filler typically consists of several key components, including:

The pharmaceutical Compact Ampoule Filler is crucial for pharmaceutical companies to efficiently and accurately fill ampoules with medications while maintaining high quality and safety standards.

Spec:

| technical parameters | ||||

| product model | LYQCL100+LYASMR 620/43+LYAGF8 | |||

| size range | 1-20ml national standard ampoules | |||

| Output(1-2ml) | 16000-22000pcs/h | |||

| Output(5-10ml) | 8000-12000pcs/h | |||

| Output(20ml) | 5000-7000pcs/h | |||

| Clarity | >99% | |||

| Breakage rate | ≤1%(whole line) | |||

| Filling Precision | ±0.5-2%(according to pharmacopoeia standard) | |||

| Water Consumption and Pressure | 0.2-0.4Mpa / 0.6-1.0m³/h | |||

| Cleaning CA Consumption and Pressure | 0.3-0.6Mpa / 35-80m³/h 0.3-1.0Mpa / 35-80m³/h | |||

| Sealed gas | Gas(liquefied gas)+oxygen, oxyhydrogen generation gas, natural gas | |||

| Oxygen consumption | 0.2-0.3Mpa,1.2-1.5m³/h | |||

| Gas consumption | 0.1-0.3Mpa,1.5-2.5m³/h | |||

| Exhaust volume | 3500-4100m³/h | |||

| Net weight | 7800(kg) | |||

| Total power | around 72kw 380V 50HZ | |||

| Outline size | around 9940x2260x2445mm | |||

Q&A for Compact Ampoule Filler

Q:What is an ampoule filling line used for?

A:An ampoule filling line is used for filling pharmaceutical products, such as liquid medications, vaccines, or solutions, into glass ampoules.

Q:What are the key components of an ampoule filling line?

A:The key components of an ampoule filling line include an ampoule washing machine, ampoule filling machine, ampoule sealing machine, inspection system, and labeling/packaging equipment.

Q:How does an ampoule washing machine contribute to the filling process?

A:The ampoule washing machine cleans and sterilizes the glass ampoules before filling to ensure product purity and cleanliness.

|