| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Carbon Steel Sheets |

|---|---|

| Brand Name: | OEM/ODM |

| Model Number: | Q235, Q345, ST37, Q195, Q215, A36, 45#, 16Mn, SPHC,SS400 |

| Certification: | SGS, TUV, ISO, CE |

| Place of Origin: | Mainland,China |

| MOQ: | 1 Ton |

| Price: | Price can be negotiated |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram |

| Supply Ability: | 5000 Tons Per Month |

| Delivery Time: | 7-20 working days |

| Packaging Details: | Standard Shipping Packaging |

| Edge: | Mill Edge, Slit Edge |

| Heat Treatment: | Normalizing, Annealing, Tempering, etc. |

| Length: | 1000mm-12000mm |

| Material: | Carbon Steel |

| Package: | Standard Export Package |

| Processing Service: | Cutting, Bending, Welding, etc. |

| Surface Treatment: | Oiled, Pickling, Galvanized, etc. |

| Test: | UT, HIC, Impact Test, etc. |

| Thickness: | 0.5mm-200mm |

| Width: | 1000mm-3000mm |

| Company Info. |

| Wuxi ShiLong Steel Co.,Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

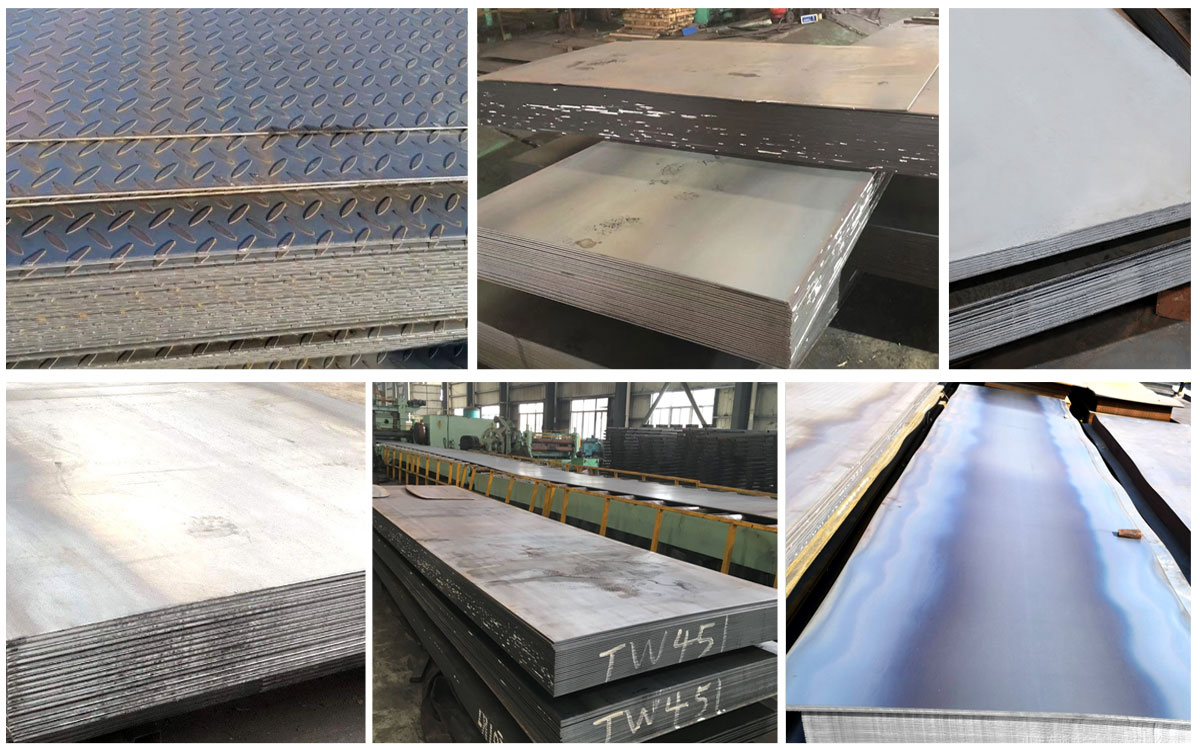

4x8ft 1045 Hot Rolled Cold Rolled Medium Mild Steel Hot Rolled

Wearing Sheet

AISI 1045 steel is a medium tensile steel that is available in black hot-rolled or normalized form. It has a tensile strength of 570-700 MPa and a Brinell hardness of 170-210.

In either normalized or hot-rolled form, AISI 1045 steel has good weldability, machinability, and high strength and impact qualities.

In either normalized or hot-rolled form, AISI 1045 steel has good weldability, machinability, and high strength and impact qualities.

Through-hardening potential of AISI 1045 steel is limited, with only portions of roughly 60 mm in size suggested for tempering and through-hardening. However, depending on conditions such as section size, kind of set up, quenching medium employed, and so on, it may be successfully flame- or induction-hardened in the normalized or hot rolled state to yield surface hardnesses in the range of Rc 54 - Rc 60.

Because AISI 1045 steel lacks appropriate alloying components, it does not react to the nitriding process.

Composition of Chemicals

| Element | Content |

|---|---|

| Carbon, C | 0.420 - 0.50 % |

| Iron, Fe | 98.51 - 98.98 % |

| Manganese, Mn | 0.60 - 0.90 % |

| Phosphorous, P | ≤ 0.040 % |

| Sulfur, S | ≤ 0.050 % |

| Physical Properties | Metric | Imperial |

|---|---|---|

| Density | 7.87 g/cc | 0.284 lb/in3 |

| Mechanical Properties | Metric | Imperial |

|---|---|---|

| Hardness, Brinell | 163 | 163 |

| Hardness, Knoop (Converted from Brinell hardness) | 184 | 184 |

| Hardness, Rockwell B (Converted from Brinell hardness) | 84 | 84 |

| Hardness, Vickers (Converted from Brinell hardness) | 170 | 170 |

| Tensile Strength, Ultimate | 565 MPa | 81900 psi |

| Tensile Strength, Yield | 310 MPa | 45000 psi |

| Elongation at Break (in 50 mm) | 16.0 % | 16.0 % |

| Reduction of Area | 40.0 % | 40.0 % |

| Modulus of Elasticity (Typical for steel) | 200 GPa | 29000 ksi |

| Bulk Modulus (Typical for steel) | 140 GPa | 20300 ksi |

| Poissons Ratio (Typical For Steel) | 0.290 | 0.290 |

| Shear Modulus (Typical for steel) | 80 GPa | 11600 ksi |

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength. Typical applications of AISI 1045 are as follows:

| Gears | Pins | Rams |

| Shafts | Rolls | Sockets |

| Axles | Spindles | Worms |

| Bolts | Ratchets | Light gears |

| Studs | Crankshafts | Guide rods |

| Connecting rods | Torsion bars | Hydraulic clamps |

AISI 1045 is subjected to forging, annealing, normalizing, stress-relieving, hardening and tempering processes – each of which is explained in more detail below:

Forging - Heat to 850°C - 1250°C (1562°F - 2282°F). Hold until the temperature is uniform. Cool in a furnace.

Annealing - Heat to 800°C - 850°C (1472°F - 1562°F). Hold until the temperature is uniform. Cool in a furnace.

Normalizing - Heat to 870°C - 920°C (1598°F-1688°F). Hold until the temperature is uniform. Soak for 10 - 15 minutes. Cool in still air.

Stress-Relieving - Heat to 550°C - 660°C (1022°F - 1220°F). Hold until the temperature is uniform. Soak for 1 hour per 25mm of section. Cool in still air.

Hardening - Heat to 820°C - 850°C (1508°F - 1562°F). Hold until the temperature is uniform. Soak for 10 - 15 minutes per 25mm of section. Quench in water or brine.

Tempering - Re-heat to 400°C - 650°C (752°F - 1202°F) as required. Hold until the temperature is uniform. Soak for 1 hour per 25mm of section. Cool in still air.

Applications

AISI 1045 is widely used for all industrial applications requiring more wear-resistance and strength. Typical applications of AISI 1045 are as follows:

| Gears | Pins | Rams |

| Shafts | Rolls | Sockets |

| Axles | Spindles | Worms |

| Bolts | Ratchets | Light gears |

| Studs | Crankshafts | Guide rods |

| Connecting rods | Torsion bars | Hydraulic clamps |

Samples

|