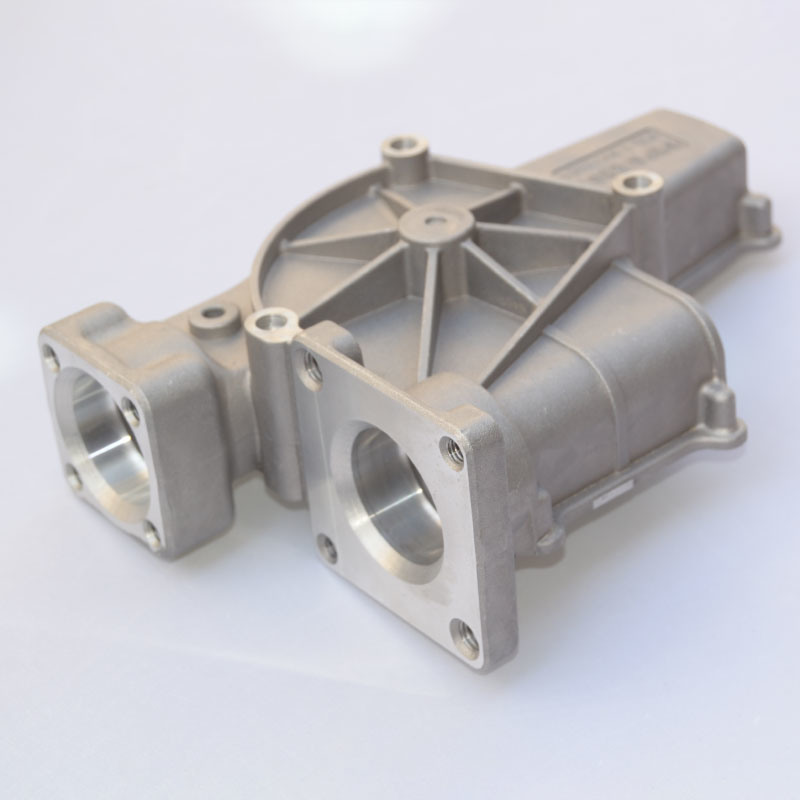

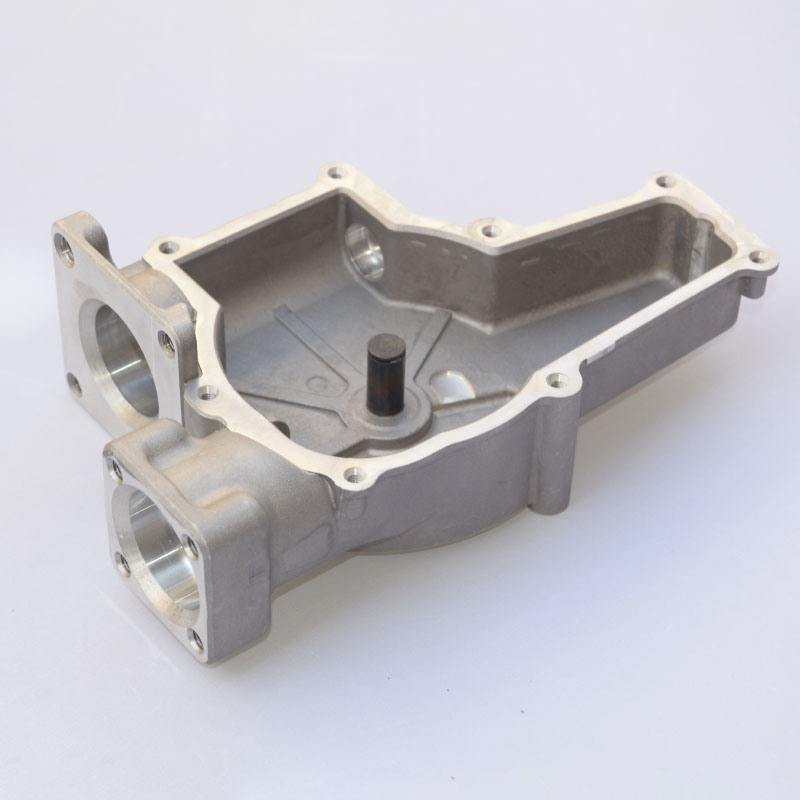

Name: Die Casting For Aluminum Electronic Tool PartsWelcome to send the drawings for alumium die casting, Zinc casting

quotation.

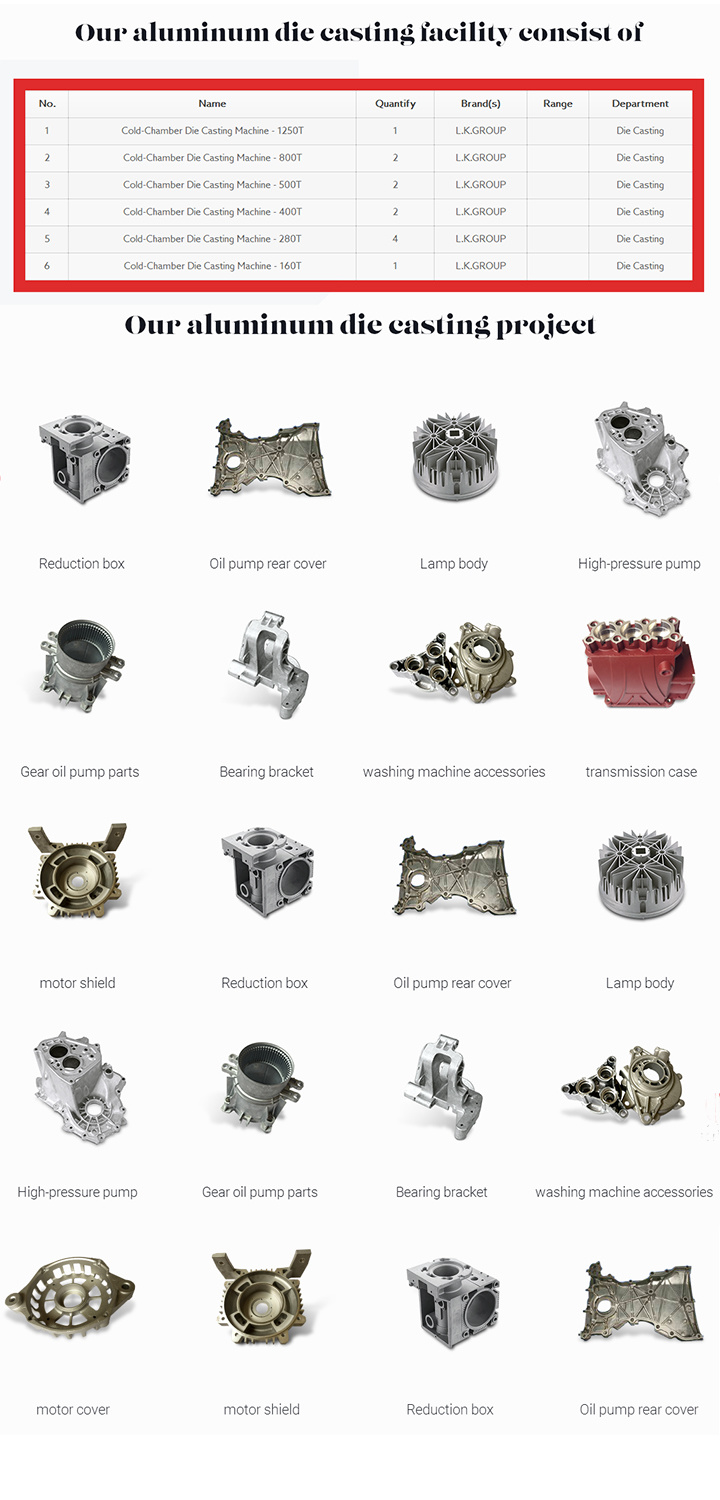

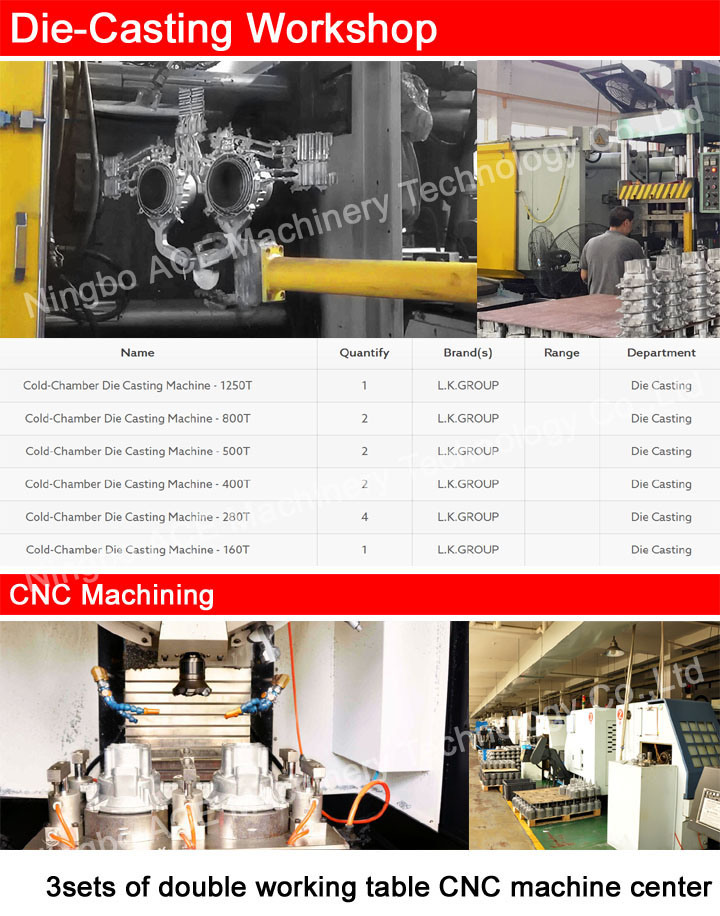

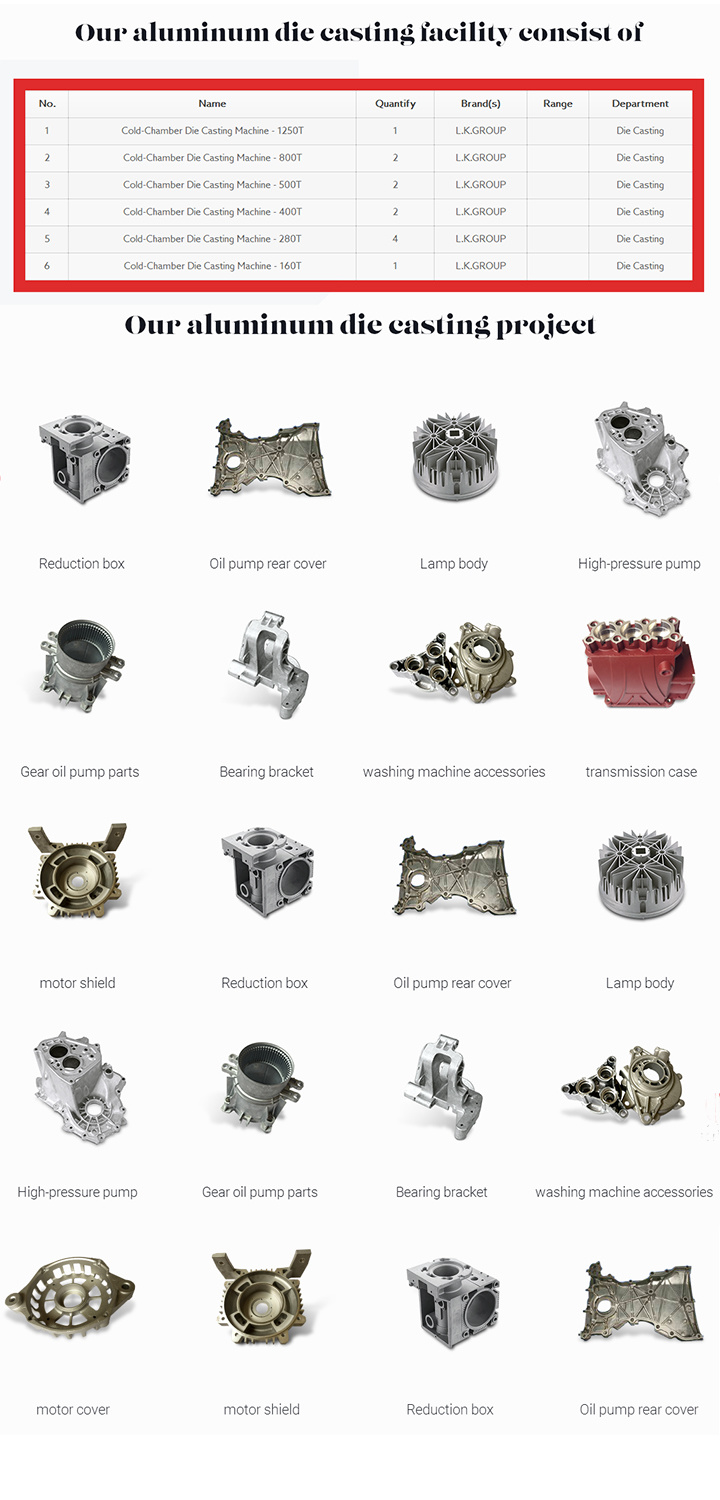

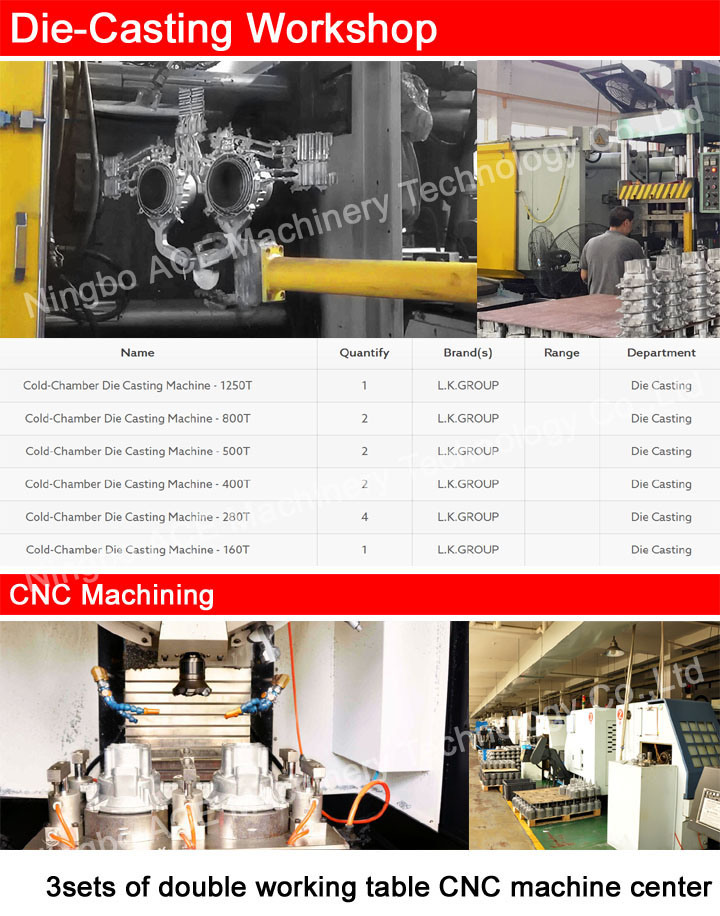

| Casting Machine | Die casting machine 88 ton, 125 ton, 200 ton, 280 ton, 400ton, 500

ton, 800 ton,1000 ton |

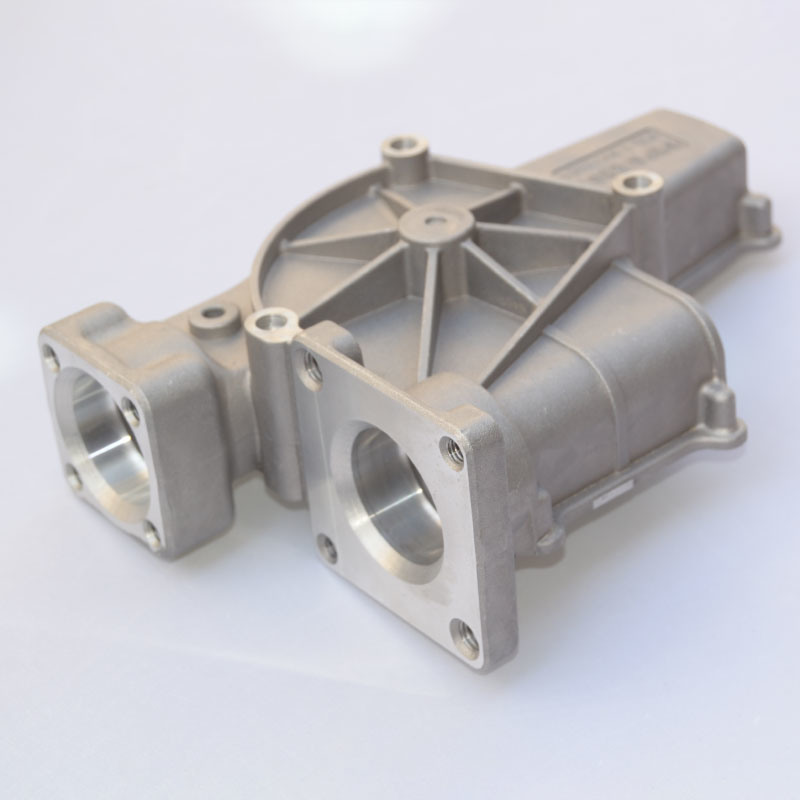

| Material | Aluminum alloy ADC10 ADC12 ADC14 A360 A380, zinc alloy |

| Casting Mold | Design, Fabrication, Test, Modification & Maintenance |

| Surface Treatment | Sandblasting, Polishing, Plating, Powder Coating, Anodisation etc |

| Accuracy | Class CT4~CT11 |

| Surface Roughness | Ra1.6~Ra6.3 |

| Machining Equipment | 3/4/5 Axis CNC machining center, CNC engraving machine, CNC milling

machine |

| CNC turning machine, high precision grinding machine, WEDM etc |

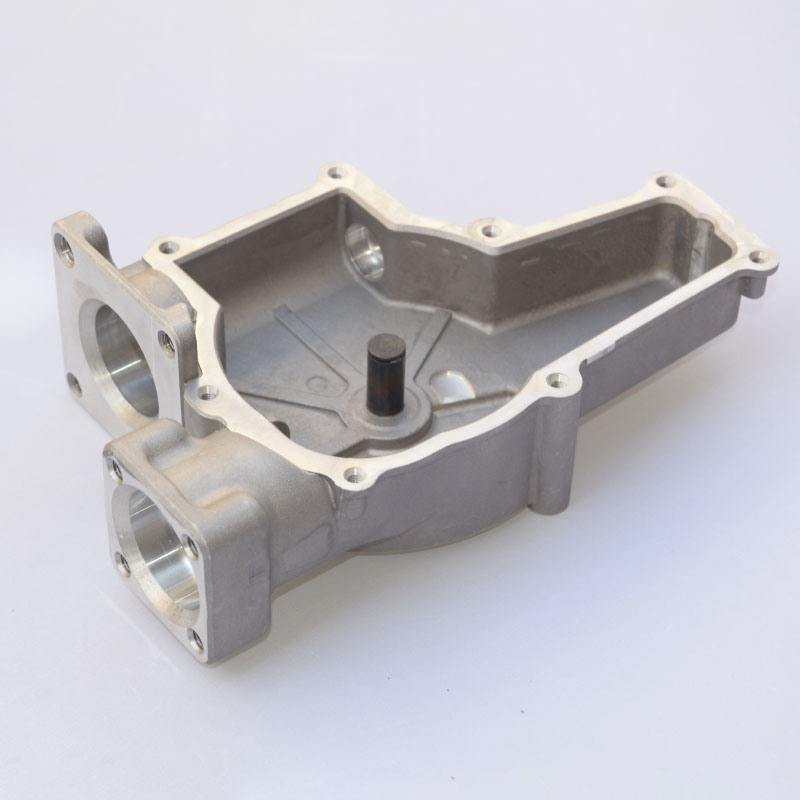

Casting is broadly defined as the process of forming a substance

into a specific shape using a mold. Metal casting employs a variety

of metals to create the molded end product and dates back thousands

of years.The most commonly materials used resources are: gray iron,

ductile iron, aluminum, steel, cooper, zinc. We have good factories

of investment casting, die casting, sandy casting etc.

Things to Consider When Choosing Casting Materials

* Level of volume required

* Cost-effectiveness

* Melting temperature

* Cooling speed

* Wear resistance

* Weight

* Damping capabilities

Industrial Casting Applications

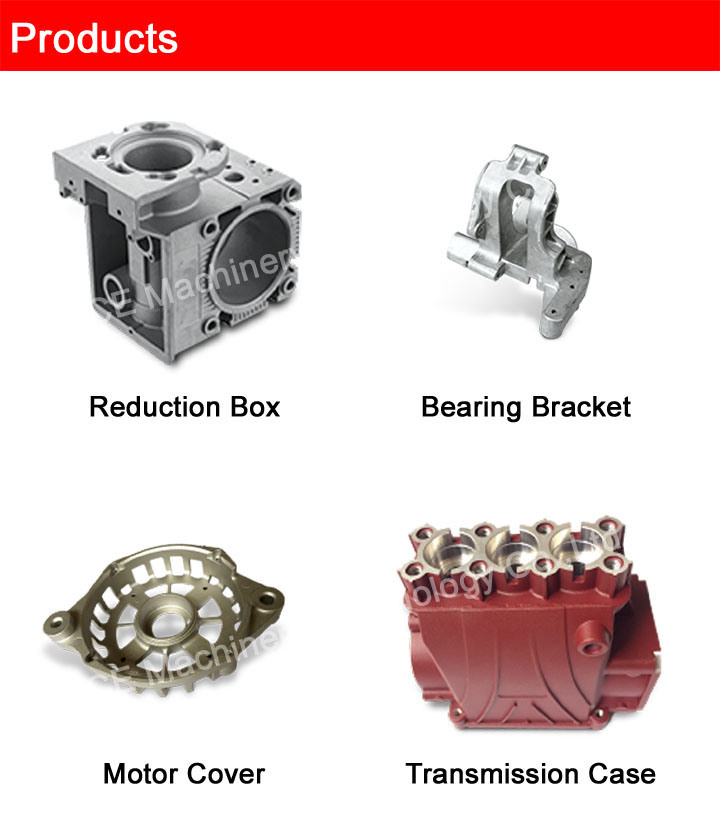

Casting is used in a large number of manufacturing process and

plays an important role in construction. Many industries depend

heavily on casting to create uniform products. Some of the leading

markets for casting materials are:

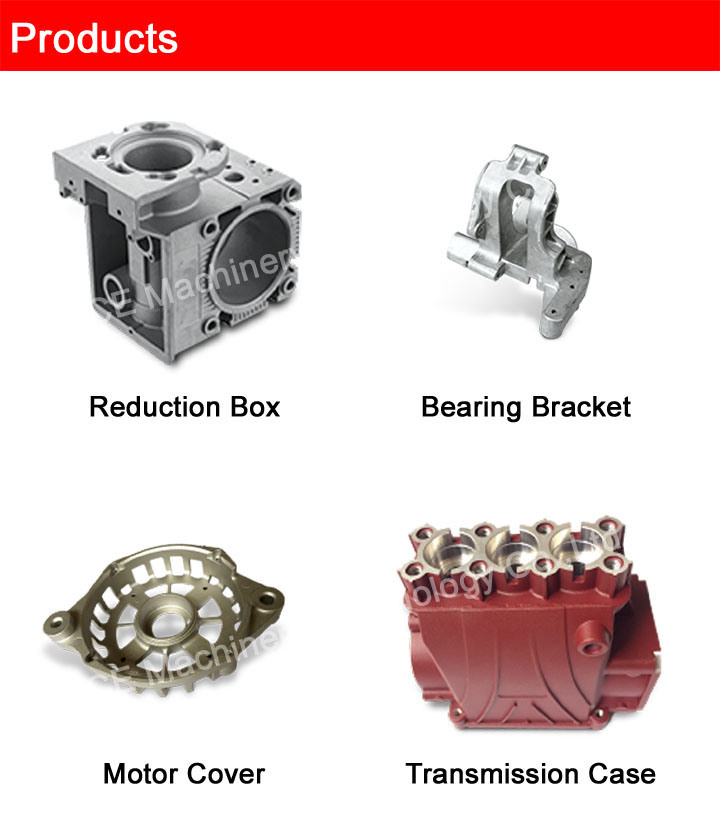

* Automotive and Light Truck

* Pipe and Fittings

* Construction, Mining and Oilfield Machinery

* Internal Combustion Engines

* Railroad

* Valves

* Farm Equipment

* Municipal Castings