| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Continuous Pyrolysis Plant |

|---|---|

| Brand Name: | Huayin |

| Model Number: | HY-10Ton |

| Certification: | CE |

| Place of Origin: | Xinxiang ,Henan,China |

| MOQ: | 1 set |

| Price: | USD 32000-48000/set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets per year |

| Delivery Time: | 15 working days |

| Packaging Details: | plastic films for pyrolysis reactor , wooden boxes for small parts |

| product name: | Continuous Pyrolysis Process Of Waste Tyres To Fuel Oil Environmental Friendly |

| Machine Type: | Batch type and continuous |

| Reactor materia: | Q345R/Q245R boiler plate |

| Cooling method: | circle water cool |

| Input raw material: | waste plastic ,PP PE PS |

| Output product: | Fuel oil , Carbon black , Steel wire, gas |

| Capacity: | 1-15ton per batch |

| Operator: | 3-4 workers |

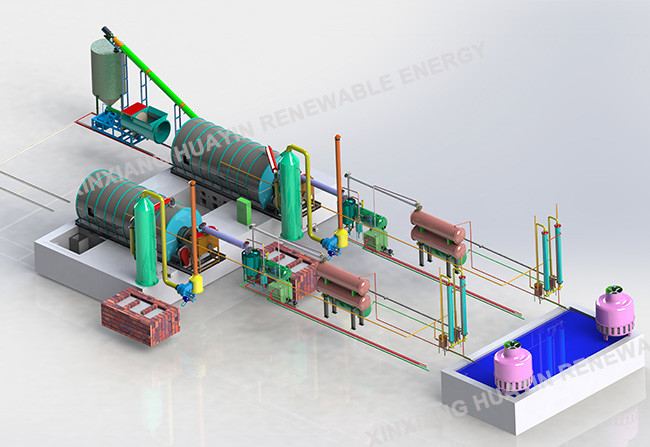

Continuous Pyrolysis Process Of Waste Tyres To Fuel Oil Environmental Friendly

Product description

With the increasing awareness of environmental protection in the world, the harmless and resourceful disposal of waste tires has become an important trend. The waste tire pyrolysis plant produced by Xinxiang Huayin processes waste tires through catalytic cracking technology to generate industrial fuel oil, carbon black and steel wire. This high-tech recycling technology has created good economic and social benefits.

Main Features

| Our advantage | |

| Reactor material | Adopt Q245R/Q235R high pressure and temperature resistance steel plate to ensure longer service life. For some special raw materials, we use a special steel plate. |

| High efficiency discharging | Adopt screw conveyor discharging device, discharge carbon black in sealed condition, no pollution, and save labor and time. |

| Integrated condensing device | All of the condensing parts have been installed together before delivery from the factory, saving installation time and ensuring welding quality |

| Auto feeding system | Auto feeder machine to feed raw material automatically, save labor and time. |

| Energy saving | The inner reactor body and outside insulation cover have good airtightness, avoiding heating loss and saving fuel. The combustible gas (that cannot be further cooled down into fuel oil )will be recycled into the furnace for heating the reactor, maximizing resource utilization. |

| Valves | All of the valves use stainless steel. |

| Non-pollution | Adopt 3 layers of ceramic packing dedusting device and water spray, finally, no black smoke discharged out. SGS emission report provided. |

| Safety devices | Alarm, auto pressure releasing device, anti backfire device, vacuum

pump to ensure the machine working smoothly. |

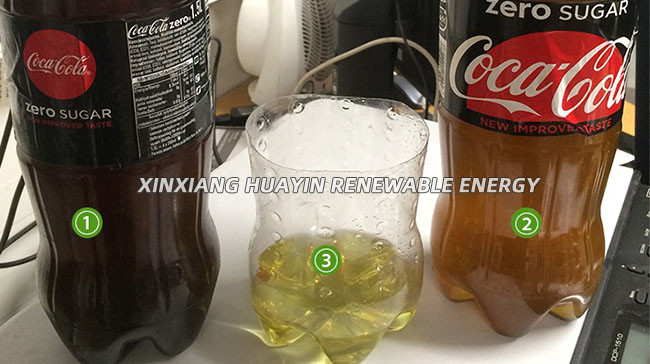

Function of the output product

1. Fuel oil (40-45%): Widely used as fuel oil in industries such as steel and iron factories, ceramics or heavy oil generators, cement factories, boiler heating, etc. Or being refined into non-standard diesel for use in trucks, tractors, etc.

2. Carbon black(30%): Be pressed into pellets for use in industrial heating;It can be ground and refined into different standards.

3. Steel wires(10%): Sold or reprocessed

4. Combustible gas(10%-15%): Can be recycled and used during production as fuel.

Specification

| Item | Content | |

| Raw materials | Waste tyre/rubber | |

| Output | 45% fuel oil, 30% carbon black, 10% steel wire, 10%-15% syngas | |

| Model | Reactor size | Capacity |

| HY1500*3000 | 1 T/batch | |

| HY2200*5500 | 5 T/batch | |

| HY2200*7500 | 7 T/batch | |

| HY2600*6600 | 8 T/batch | |

| HY2800*6000 | 9 T/batch | |

| HY2800*6600 | 10 T/batch | |

| HY2800*8000 | 15 T/batch | |

| Remarks | Support customization | |

| Reactor material and thickness | Q345R/Q245R/310S (Boiler plate/stainless steel) 16mm/18mm | |

| Land area | 300-400㎡ (L30-40m*W10m) | |

| Number of workers | 3-4 | |

| Oil density and calorific value | 0.89g/cm³&44.30KJ/KG | |

| Processing time and power | 10-24 hours. Averagely 15KW/h | |

| Certification | CE, ISO, BV, SUV, SGS Oil Report, Emission Report, 11 patents | |

Our service

1. One-stop solution. We have more than 20 years of rich experience

in manufacturing waste pyrolysis plants. We pay more attention to

customer experience and customer satisfaction. As long as you need

it, we are able to provide you with a better quality complete

production line.

2. We have our own factory and trading company, no middlemen, more

cost-effective, and it is more convenient for you to replace

related parts, as long as there is a problem, we can provide a

solution immediately, product quality is guaranteed.

3. We promise that our plants are efficient and have a long service

life to ensure that you can quickly produce in batches.

4. Delivery time is 15-25 days.

5. We can send engineers on-site to guide installation and train

your workers.

6. One-year warranty, lifelong maintenance of the equipment, providing professional use guidance services.

|