| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Continuous Pyrolysis Plant |

|---|---|

| Brand Name: | Huayin |

| Model Number: | HY-10Ton |

| Certification: | CE |

| Place of Origin: | Xinxiang ,Henan,China |

| MOQ: | 1 set |

| Price: | USD 32000-68000/set |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 200 sets per year |

| Delivery Time: | 15 working days |

| Packaging Details: | plastic films for pyrolysis reactor , wooden boxes for small parts |

| Function: | pyrolysis plastic machine |

| Machine Type: | Batch type and continuous |

| Reactor materia: | Q345R/Q245R boiler plate |

| Cooling method: | circle water cool |

| Input raw material: | waste plastic ,PP PE PS |

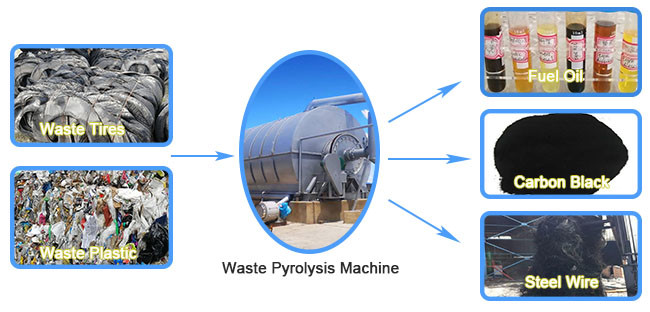

| Output product: | Fuel oil , Carbon black , Steel wire, gas |

| Capacity: | 1-15ton per batch |

| Operator: | 3-4 workers |

Batch And Continuous Type Waste Plastic Recycling To Fuel Oil Plant High Profit

The plastic waste that can be seen everywhere seriously pollutes our living environment, how to dispose of this plastic waste properly is increasingly important. Huayin waste plastic pyrolysis plant can recycle the waste plastic to fuel oil, carbon black, and gas through pyrolysis technology, the whole process is environmentally friendly and brings you large profit .

Main Features

1. High automation: Loading used tires/plastic into the pyrolysis reactor with 50ton hydraulic pressure, so the auto feeder can help you save labor and load more waste raw material, compared with manual feeding, the automatic feeder is more efficient.

2. 100% safety: The pyrolysis reactor is made of Q245R/Q345R boilerplate, which is high pressure and high-temperature resistance that ensure its longer service life. Adding perfect hot seal technology to ensure operation safely.

3. Environmental friendly: Flue gas is purified by ceramic packing dedusting device, finally no black smoke emitted.

4. High efficiency discharging device: Discharge carbon black from pyrolysis reactor after the production is finished in a sealed condition, no pollution and saves labor and time.

5. Strictly quality control. All of the steel plates are purchased from China's famous company " Anyang Iron and Steel Co., Ltd ", and the raw material inspection certificate can be provided to customers. For each set of machines, we will do ultrasonic nondestructive testing, and automatic submerged welding technology to ensure the machine quality.

Oil ratio

Different plastic waste material has different oil yield.

| Raw materials | Oil ratio | Raw materials | Oil ratio |

| PP (Microwave oven food box/yogurt bottles, ect.) | 50%-75% | ABS(engineering plastic) | 40% |

| PS(fast food boxes/instant noodle boxes) | 50%-75% | Leftovers of paper | Wet 15-20%,Dry 60% |

| PE(plastic film/plastic wrap) | 50%-75% | House garbage | 35%-50% |

| Plastic cable | 80% | Plastic bags | 50% |

Specification

| Item | Content | |

| Raw materials | Waste tyre/rubber | |

| Output | 45% fuel oil, 30% carbon black, 10% steel wire, 10%-15% syngas | |

| Model | Reactor size | Capacity |

| HY1500*3000 | 1 T/batch | |

| HY2200*5500 | 5 T/batch | |

| HY2200*7500 | 7 T/batch | |

| HY2600*6600 | 8 T/batch | |

| HY2800*6000 | 9 T/batch | |

| HY2800*6600 | 10 T/batch | |

| HY2800*8000 | 15 T/batch | |

| Remarks | Support customization | |

| Reactor material and thickness | Q345R/Q245R/310S (Boiler plate/stainless steel) 16mm/18mm | |

| Land area | 300-400㎡ (L30-40m*W10m) | |

| Number of workers | 3-4 | |

| Oil density and calorific value | 0.89g/cm³&44.30KJ/KG | |

| Processing time and power | 10-24 hours. Averagely 15KW/h | |

| Certification | CE, ISO, BV, SUV, SGS Oil Report, Emission Report, 11 patents | |

Our company

Established in 1993, Xinxiang HUAYIN Renewable Energy Equipment Co., Ltd is an environmental protection plant manufacturer integrating product R&D, design, production, marketing, installation and after-sales. HUAYIN Energy enjoys a technical and service team composed of more than 30 experienced engineers and a number of invention patents, CE, SGS, ISO9001 and ISO14001 certifications.

Our service

1. Help the client do the Feasibility Analysis Report according to the customer’s local market.

2. Design the layout drawings according to the site of customers.

3. For each set of pyrolysis plants, one engineer will be sent to guide the installation, test the machine and train the workers.

4. One-year warranty for the complete plant.

|