| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | SMT Reflow Soldering Machine |

|---|---|

| Brand Name: | HONREAL |

| Model Number: | HRE-430 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1Set |

| Price: | Negotiable |

| Payment Terms: | L/C, T/T, Western Union |

| Supply Ability: | 100 Sets per Month |

| Delivery Time: | 20 Days |

| Packaging Details: | Woodencase |

| Heating zones: | 4 zones |

| Heating tunnel: | 980mm |

| Dimension: | L1920*W750*H1250 |

| Rising time: | 15 mins |

| Controlling type: | Touch screen and PLC |

| Heating method: | Fully forced air convection |

| Temperature controlling: | PID close-loop control, SSR drive |

| Temperature range: | Ambient---350℃ |

| Temperature accurancy: | ±1 ℃ |

| Max PCB width: | 300mm |

| Company Info. |

| Shenzhen Honreal Technology Co.,Ltd |

| Verified Supplier |

| View Contact Details |

| Product List |

Smd Soldering Oven Small Mini Surface Mount Reflow Oven Pcb Drying Oven

Product introduction:

1.Streamline shape design make the oven looks great. Touch screen and PLC controlling system .It can save 50 groups temperature parameters and provide extra 2 ports for profile testing.

2.The software has the functions like , temperature setting and editing, PCB parameter menu, and profile testing, alarms and multi-languages conversion.

3.Brand electrical component like Schneider (German) breaker, KETE(Korea) SSR, Omron (Japan) box breaker. Meanwhile the CE certificated blower is specially design for lead-free reflow oven. It runs stable and lower noise.

4.Upper zone and hood can be opened by the electrical screw automatically. It is very convenient for cleaning and maintenance.Electrical pole will hold the upper zone andn cover, even when power is off suddently, the cover will not drop down. It's much safer than the air cylinder holder.

5.Specially designed Ni-Cr heater filaments, provide a very quick ramp up time. It takes just 15 minutes from ambient to setting temperature.

6.The inner tunnel of the oven is made of stainless steel which easy for cleans.

7.The entire upper and bottom zones are forced air convection; provide great temperature accuracy and uniform.

8.Stainless steel mesh belt and pin chain conveyor work together.

9.Industrial chiller provides better cooling performance.

10.SMEMA interface.

Machine's parameters:

| Machine | HRE-430 |

| Heating zones | Upper 4 zones |

| Bottom 4 zones | |

| Heating tunnel | 980mm |

| Dimension | L1920*W750*H1250 |

| Net weight | about 280Kg |

| General power | 23KW |

| Power consumption | Approx.3--7KW |

| Rising time | 15 mins |

| Controlling type | Touch screen and PLC |

| Heating method | Fully forced air convection |

| Temperature controlling | PID close-loop control, SSR drive |

| Temperature range | Ambient---350℃ |

| Temperature accurancy | ±1 ℃ |

| Temperature uniform | ±2 ℃ |

| Cooling | One cooling zone,fans for cooling |

| Conveyor method | Mesh belt and chain conveyor |

| Conveyor height | 900±20mm |

| Mesh belt width | 330mm |

| Max PCB width | 300mm |

| PCB clearance | 30mm |

| Conveyor direction | Left to right |

| Conveyor speed | 0-900mm/min |

| Hook lift | Manual |

| Power supply | 380v,3ph,50hz |

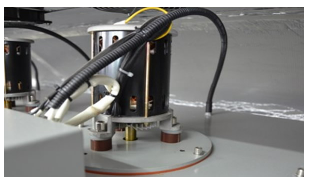

New designing makes easy to replace hot air motor.

1. Remove these screws

2.Take out whole structure (blower motor+ rounded fixing plate+ fan).

3.Take out motor fan which is fixed by set screw.

4. Replace blower motor and fan.

5.Fix the rounded fixing plate with blower motor by screws.operator can finish that within 15 minutes.

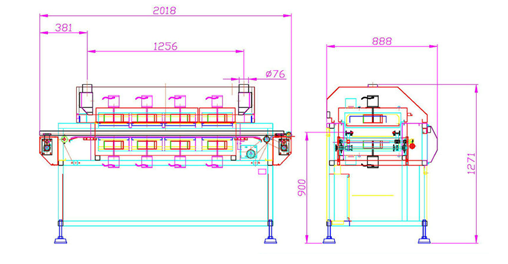

Machine schematic (HRE-430) :

Services and commitments

Before buying the product, we will be a comprehensive analysis of

the views and requirements and recommend it to the actual needs of

customers with the most suitable products and let customers know

that the performance characteristics of the selected product

referred to in accordance with customers.

In purchasing the products, we promise to allow customers to

clearly know the completion of the product. In strict accordance

with the relevant provisions of the contract terms of production,

delivery, to ensure product intact and in place within the

stipulated time to customer requirements.

The company promises:

We highly value your feedback on the quality of information, all

the information will be given to the quality of feedback responses;

In accordance with the contract requirements for the installation,

commissioning and training of technical personnel for the buyer

sold the equipment.

We provide long-term technical support, Our company has adequate

supply of consumable buyer if requested to order spare parts, our

company can provide timely.

Q:How can you guarantee your sales’ quality?

A:We guarantees that every set of machines are under rigorous

testing before they are delivered to you, to ensure the excellent

performance of all products.

Q:How is the training?

A:After buying our machines, your engineers can go to our company or it is so easy to operate

the machine according the training video and user manual,the user manual will come with the machine together.

Q: I would like to ask you if it's possible to have my logo on the

product.

We hope you know that our company perfectly support customized logo

service,we’re do this. Besides, it's totally free,so just tell us

your requirements.

Q: Is it hard to use these machines?

A: No, not hard at all. For our previous clients, at most 2 days is enough to learn to operate the machines.

|