| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Turning And Milling Services |

|---|---|

| Brand Name: | WINS TECH |

| Model Number: | WCMP55 |

| Certification: | ISO 9001:2015, ISO 14001, IATF16949:2016 |

| Place of Origin: | China |

| MOQ: | No MOQ |

| Price: | Negotiation |

| Payment Terms: | T/T |

| Supply Ability: | 100k per month |

| Delivery Time: | 1~5 days |

| Packaging Details: | standard air packing |

| Surface treatment: | Anodizing,electroplating,Sandblasting,Powder Coating,anodized |

| Tolerance: | + - 0.02 mm |

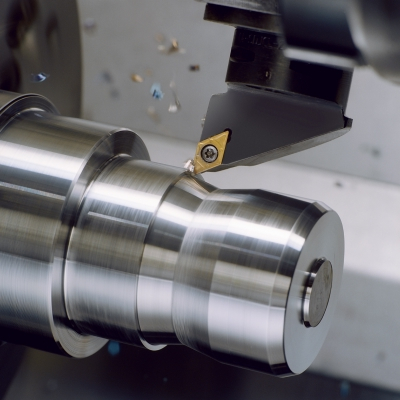

| Process: | Turning/Milling/Grinding/Machining,Cnc milling method |

| Application: | Auto Part,Ecomomical,Medical Equipments,Auto Part precision cnc metal parts processing |

| Material: | aluminum |

| Service: | OEM ODM,Customized OEM\CNC Machining Service,Customized OEM Aluminum CNC Machining |

| Company Info. |

| Shenzhen Wins Tech Limited |

| View Contact Details |

| Product List |

CNC Machined parts are precise and have high tolerance specifications; the process itself is fast and a wide range of materials can be used. Due to these qualities, CNC Machining is popular choice in the automotive industry

Coating services

Surface finishing options:

Heat treatment options:

Precision CNC machining parts and rapid prototyping, metal parts, performance plastics, and low-mid volume rapid machining production runs. When it comes to China CNC machining or custom CNC machining in general, our approach is: provide highly flexible rapid low volume manufacturing solutions that deliver superior parts fast

At WINS TECH LIMITED, we know your time is valuable – and we’re passionate about helping you save more of it. When you upload your files, we’ll get you a quote within one business day – and our network of highly experienced partners will ensure the finished CNC products are of the highest quality with short lead times.

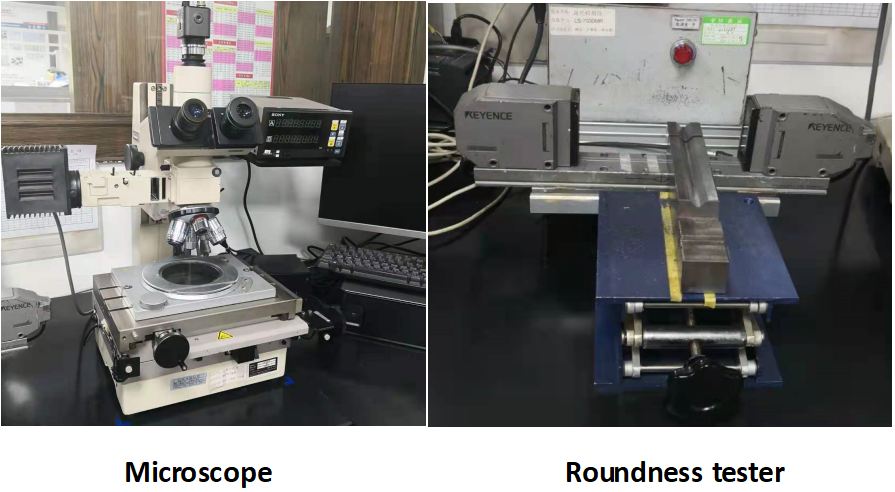

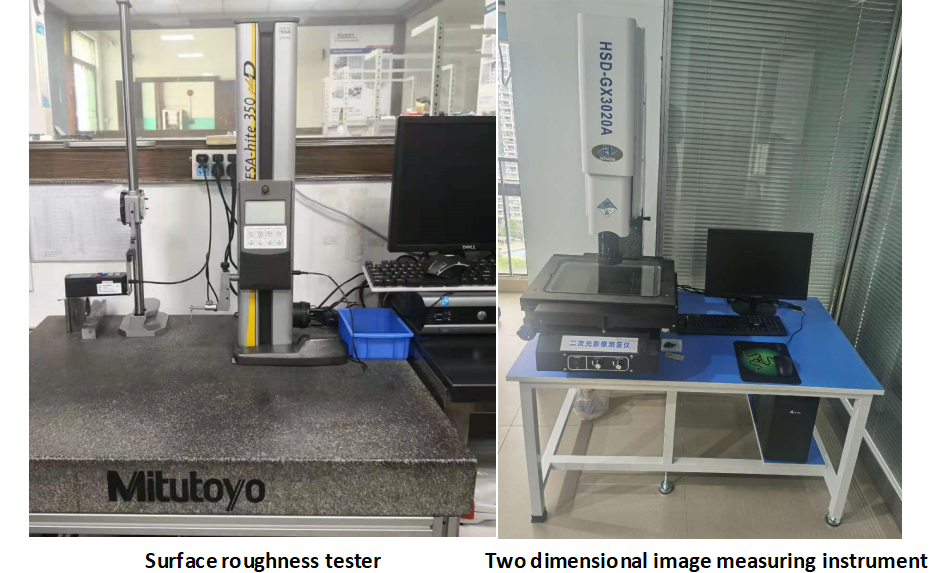

WINS TECH LIMITED EQUIPMENT LIST | ||||||||

| Item | Classes | Equipment | Brand | Quantity | Unit | Service time | on state | Notes |

| 1 | General-purpose machine tool | Miller | Jaguard | 3 | set | 2 years | under normal service conditions | |

| 2 | Jaguard | 3 | set | 2 years | under normal service conditions | |||

| 3 | Foshan machine | 1 | set | 2 years | under normal service conditions | |||

| 4 | Turning-lathe | Guangzhou Nanfang | 1 | set | 2 years | under normal service conditions | 6140D | |

| 5 | Digital controlled lathe | CNC lathe | Taihe | 6 | set | 2 years | under normal service conditions | 46 line cutter machine |

| 6 | 4 axis precision automatic lathe | SUPVAN | 3 | set | 2 years | under normal service conditions | ||

| 7 | 5 axis precision automatic lathe | NONO | 3 | set | 2 years | under normal service conditions | ||

| 8 | Digital controlled lathe | CNC machining center | 4 | set | 0.1 year | under normal service conditions | 850H | |

| 9 | CNC machining center | Xin Tenghui | 1 | set | 2 years | under normal service conditions | 1280H | |

| 10 | CNC machining center | Xin Tenghui | 1 | set | 2 years | under normal service conditions | 750H | |

| 11 | CNC machining center | J-Y CNC | 3 | set | 2 years | under normal service conditions | 650H | |

| 12 | CNC machining center | DeMarco | 2 | set | 1 year | under normal service conditions | 2150H | |

| 13 | CNC machining center | 2 | set | 2 years | under normal service conditions | 46 line cutter machine | ||

| 14 | CNC lathe | Taihe | 8 | set | 1 year | under normal service conditions | 46H | |

| 15 | Cutter tower turning milling compound machine | 1 | set | 0.5 year | under normal service conditions | 46H | ||

| 16 | CNC turning milling compound machine | Taihe | 3 | set | 1 year | under normal service conditions | 325-355 | |

| 17 | Line cutting equipment | wedm-ls | SODICK | 3 | set | 5 years | under normal service conditions | 500H |

| 18 | wedm-hs | Changan | 2 | set | 1 year | under normal service conditions | 540H | |

| 19 | wedm-hs | Taizhou | 2 | set | 1 year | under normal service conditions | 540H | |

| 20 | Auxiliary equipment | hand drilling machine | 1 | set | 1 year | under normal service conditions | ||

| 21 | perforating machine | 1 | set | 1 year | under normal service conditions | |||

| 22 | tapping machine | 2 | set | 1 year | under normal service conditions | |||

| 23 | chamfering machine | 2 | set | 1 year | under normal service conditions | |||

| 24 | sharpener | 2 | set | 1 year | under normal service conditions | |||

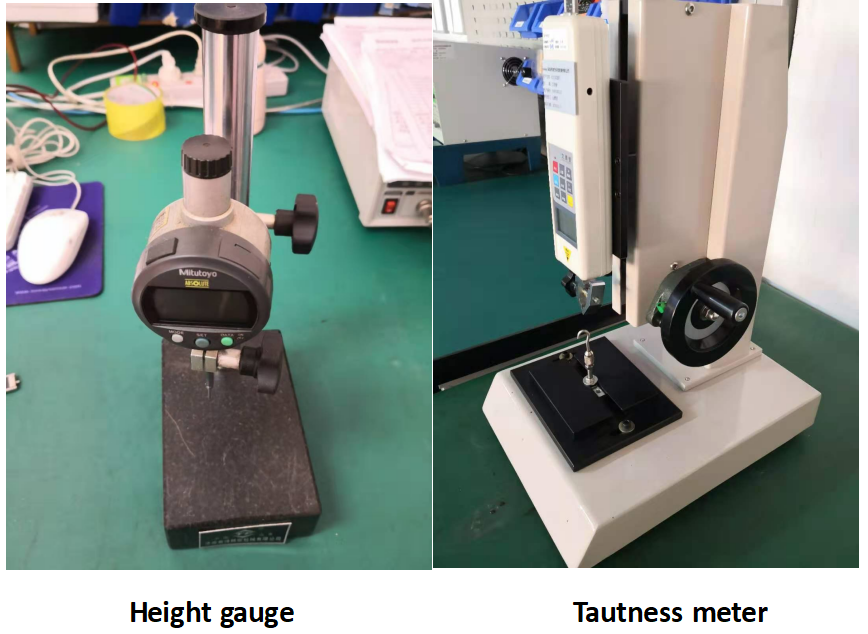

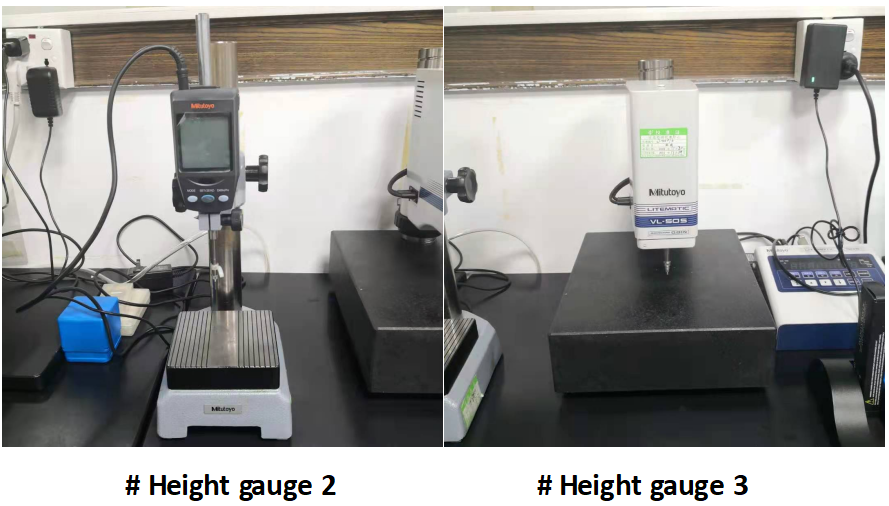

| 25 | Inspection equipment | height gauge | 3 | set | 1 year | under normal service conditions | ||

| 26 | Two dimensional image measuring instrument (YVM) | 1 | set | 1 year | under normal service conditions | |||

| 27 | Three dimensional detection | 1 | set | 1 year | under normal service conditions | |||

| 28 | Surface roughness tester | 2 | set | 1 year | under normal service conditions | |||

| 29 | tensile machine | 2 | set | 1 year | under normal service conditions | |||

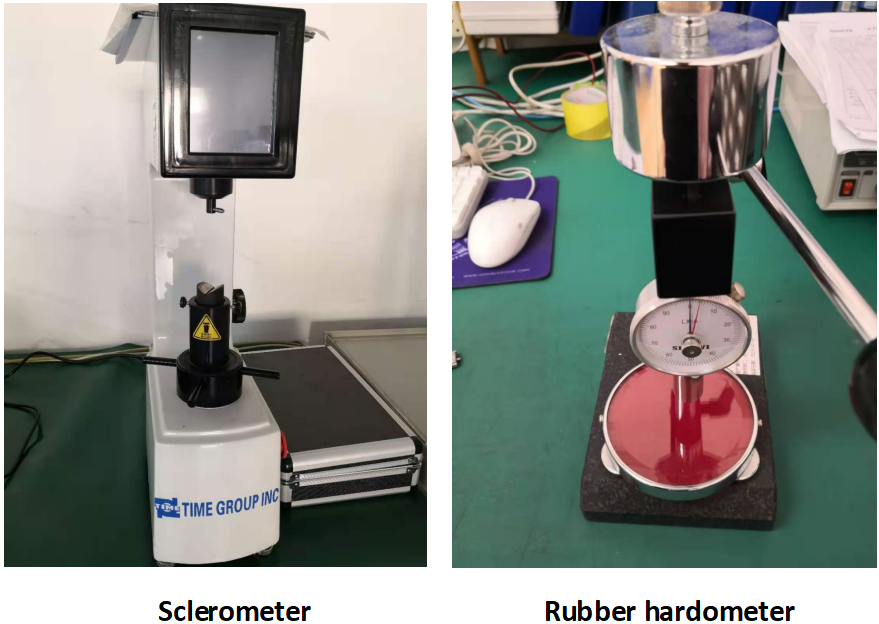

| 30 | sclerometer | 2 | set | 1 year | under normal service conditions | |||

| 31 | microscope | 1 | set | 1 year | under normal service conditions | |||

| 32 | True roundness detector | 1 | set | 1 year | under normal service conditions | |||

Quality inspection:

Zero defect rate target, automatic inspection equipment;

One-stop customized manufacturer accept all kinds of materials;

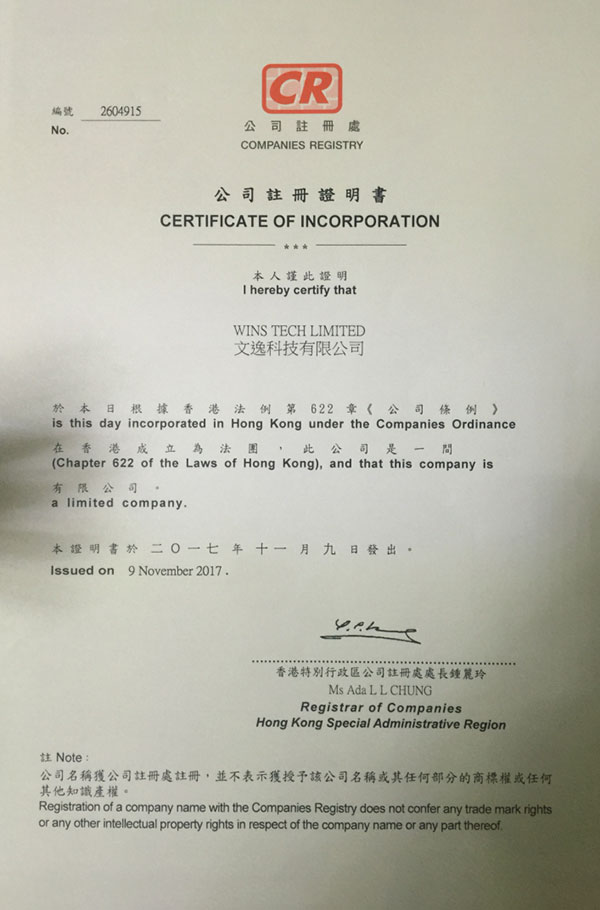

About WINS TECH LIMITED:

· March, 2012: WINS TECH LIMITED Set Up

· October, 2014: ISO9001 Certificate

· September, 2017: WINS TECH LIMITED HongKong branch office Set Up

· December, 2017:start to expand overseas markets

· May, 2019: 2 automatic production lines set up, 4 production lines in total, factory production capacity over 1 million

· May, 2020: ISO14001 Certificate

· September, 2021: IATF16949 Certificate

· 2022~ : to be continue

Certifications

Wins tech limited guarantees the quality of your machined parts with our ISO 9001:2015, ISO 14001, and IATF16949 certified quality management system, ITAR registration, and options to add inspections, hardware traceability, material certifications, and CoCs. We accept technical drawings and have support teams to ensure you get quality CNC machined parts on time.

High speed fabrication and prototyping!

We accept OEM and ODM, customizable!

We warmly welcome clients from all over the world to come to our

factory for visit and cooperation!

|