| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Milling Service |

|---|---|

| Brand Name: | Yexin |

| Model Number: | CNC78-3 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Dongguan, China |

| MOQ: | 1 pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 100000 pcs/month |

| Delivery Time: | 5-15 work days |

| Packaging Details: | Standard Export Carton, Wooden Case, etc. |

| Application: | Automotive, Aerospace, Industrial Machinery, Medical, Consumer Electronics, Robotics & automation, etc. |

| Material: | Aluminum, Brass, Stainless Steel, Plastic, Wood, Copper, etc. |

| Processing: | CNC Turning, Milling, Drilling, etc. |

| Service: | OEM, ODM, Customized |

| Surface Finish: | Anodizing, Polishing, Painting, etc. |

| Tolerance: | ±0.01mm, ±0.005mm, etc. |

| Delivery: | By Express, Air, Sea, etc. |

| Drawing Format: | PDF, CAD, STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, etc. |

| Inspection: | 100% Inspection |

| Keyword: | Custom CNC Milling Service |

| Company Info. |

| Dongguan Yexin Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

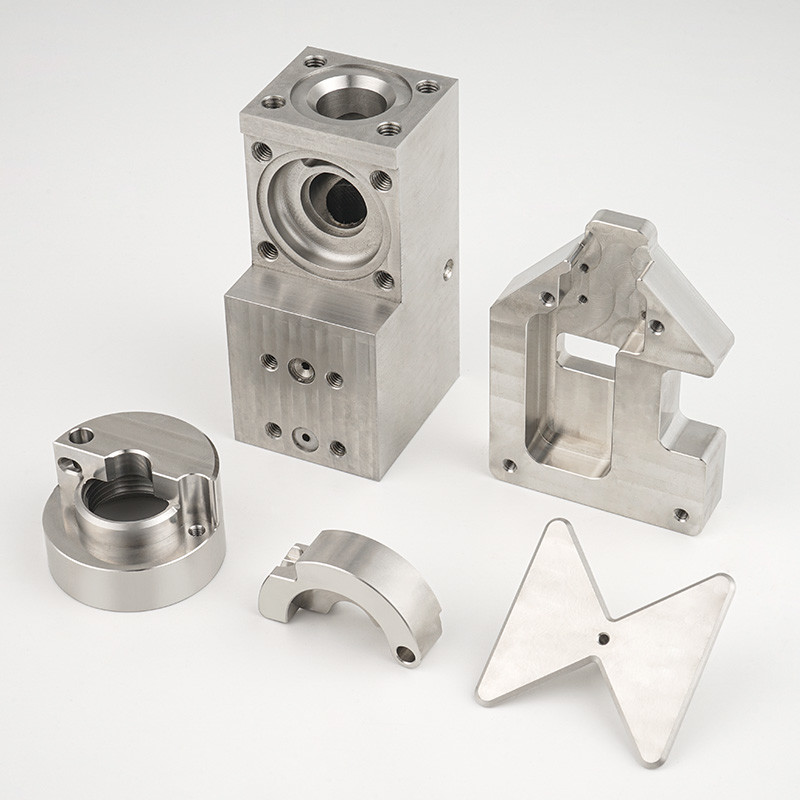

OEM ODM CNC Aluminum Parts Lathe Machining Service Machine Aluminum

Mechanical CNC Milled Parts

CNC milling involves the use of automated cutting machines equipped with a rotating

spindle-head to remove unwanted material.

These machines come in various sizes and configurations, allowing for versatile applications.

While CNC milling is commonly employed for cutting tougher metals, it can also handle materials

ranging from plastics and aluminum to stainless steel and titanium.

Product Details

Materials Commonly Used in CNC Milling

CNC milling encompasses a wide range of materials, with three main

categories: plastics, soft metals,

and hard metals.

These materials are versatile and suitable for various machining applications. Examples of materials

used in CNC milling include aluminum, bronze, copper, ceramics, plywood, various types of steel,

stone, wood, and zinc, among others.

Certain materials, such as aluminum and mild steel, are favored by machinists due to their ease of

workability and excellent properties, making them industry standards for many applications.

| Common Materials for CNC Machining | |

| Material | Properties |

| Aluminum | 2024: Good fatigue resistance and strength; excellent toughness at moderate to high strength levels; improved fracture toughness |

| 6061: Excellent machinability, low cost, and versatility | |

| 7075: High strength, hardness, low weight, and heat tolerance | |

| Brass | Versatile and highly attractive copper/zinc alloy with warm yellow color accommodates severe forming/drawing |

| Copper | High ductility and high electrical and thermal conductivity; develops attractive blue-green surface patina over time |

| Stainless Steel | Excellent machinability and outstanding uniformity; good workability and weldability, high ductility and formability |

| Steel Alloy | Mix of chromium, molybdenum, and manganese yields toughness, good torsional and fatigue strength |

| Steel Mild Low Carbon | High machinability and weldability, high stiffness; good mechanical properties, machinability, and weldability at low cost |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive, and medical industries |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

| Nylon | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM | High stiffness, excellent thermal & electrical properties, relatively brittle |

| CNC Milling Tolerances | ||

| Limits for nominal size | Plastics | Metals |

| 0.5mm* to 3mm | ±0.1mm | ±0.05mm |

| Over 3mm to 6mm | ±0.1mm | ±0.05mm |

| Over 6mm to 30mm | ±0.2mm | ±0.10mm |

| Over 30mm to 120mm | ±0.3mm | ±0.15mm |

| Over 120mm to 400mm | ±0.5mm | ±0.20mm |

| Over 400mm to 1000mm | ±0.8mm | ±0.30mm |

| Over 1000mm to 2000mm | ±1.2mm | ±0.50mm |

| Over 2000mm to 4000mm | ±2.0mm | |

*Please clearly indicate tolerances for nominal sizes below 0.5mm on your technical drawing. | ||

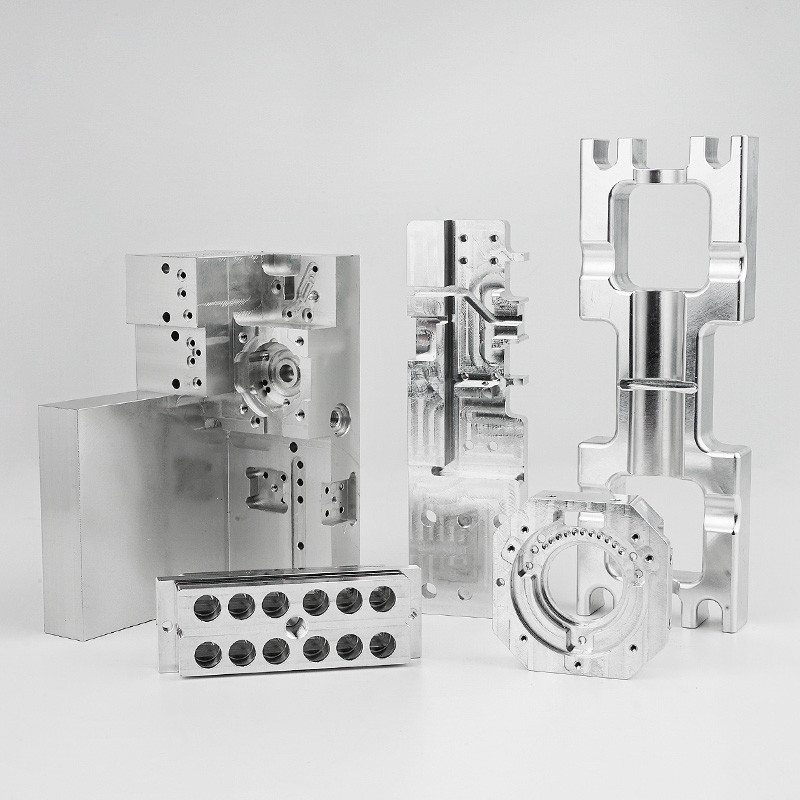

Application for CNC Milling Parts

CNC machining is a go-to manufacturing process to get precision parts, whether for prototyping

or end-use production.

It is widely used throughout the aerospace, medical, automotive industries for its ability to

rapidly manufacture precise parts in production-grade materials, such as:

1. housings and enclosures

2. brackets

3. fixtures for manufacturing

4. gears and bearings

5. internal mechanical components

6. medical instrumentation

Company Profile

FAQ's

1. How do you get the most out of CNC milling?

Efficiency and cost-effectiveness in CNC milling can be achieved through various strategies,

primarily centered on designing parts that are "Simple" and adhere to "Standard" specifications.

When you design parts with straightforward features that can be manufactured using

standard-sized tools, you enhance the likelihood of successful outcomes.

While complexity has its place in certain situations, it typically results in longer lead times and

increased costs.

For example, a part with intricate features may pose manageable challenges when crafted from

aluminum but may become considerably more complex and costly when produced from plastic,

especially in mass production scenarios.

In summary, prioritize simplicity and standardization in your designs whenever possible.

While there may be instances where complexity or specialized materials are warranted, be mindful

that they can significantly impact the milling process in terms of intensity and cost.

2. Design Considerations for CNC Milling

When designing parts for CNC milling, consider the following guidelines:

1. Leverage Precision: CNC milling machines offer high precision, so take advantage of this

capability in your designs.

2. Avoid Deep Pockets: Deep pockets can be challenging to machine, so try to minimize their use.

3. Address Sharp Inside Corners: Sharp inside corners can pose machining difficulties, so consider

using radii to ease machining.

4. Apply Chamfers: Add chamfers to top edges to reduce sharpness, improve aesthetics, and f

acilitate machining.

5. Implement Fillets: Apply fillets to the bottom of pockets to reduce the risk of stress fractures,

especially if the component will be subjected to stress.

6. Be Cautious with Thin Walls: Thin walls and delicate shapes may be challenging to machine,

as they might not withstand the cutting pressure.

7. Simplify Curves: When possible, design shapes that do not involve complex curves in multiple

axes, as they can be tricky to hold during machining processes.

|