| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

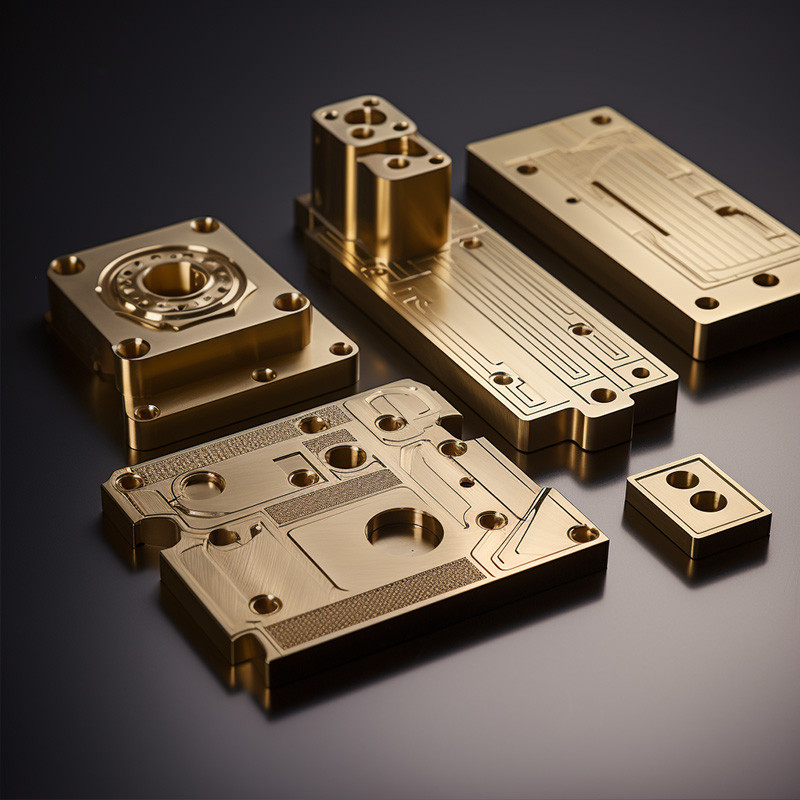

| Categories | CNC Brass Parts |

|---|---|

| Brand Name: | Yexin |

| Model Number: | BR5 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Dongguan, China |

| MOQ: | 1 pcs |

| Price: | Negotiable |

| Payment Terms: | Paypal, T/T, Western Union, L/C, D/A, D/P |

| Supply Ability: | 180000 pcs/month |

| Delivery Time: | 3-12 work days |

| Packaging Details: | Standard Export Carton, Wooden Case, etc. |

| Application: | Aerospace, Automotive Industry, Consumer Electronics, Medical, Oil and Gas Machine, etc. |

| Material: | Brass |

| Processing: | Turning, Milling, Broaching, Drilling, Wire EDM, Rapid Prototyping, etc. |

| Service: | OEM, ODM, Customized |

| Equipment: | CNC Machining Centers |

| Tolerance: | ±0.01mm, ±0.005mm, etc. |

| Delivery: | By Air, Sea, Express, etc. |

| Drawing Format: | CAD, PDF, STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, etc. |

| Keyword: | CNC Brass Parts |

| Company Info. |

| Dongguan Yexin Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

Custom CNC Part Brass CNC Turning Spare Parts Auto CNC Manufacture Parts

CNC machining represents the predominant subtractive manufacturing technology in

contemporary industrial processes.

It stands as an exceptionally flexible and robust method for the production of tailor-made

metal and plastic parts.

Leveraging CAD models, CNC machines execute precise material removal from solid blocks

through a diverse range of cutting tools.

In essence, CNC machining yields components characterized by precise tolerances and

remarkable material properties.

Its applicability spans from individual projects to low-to-medium volume production runs

(up to 1,000 parts), primarily due to its exceptional repeatability.

Product Details

Brass is renowned for its exceptional machinability, making it an excellent choice for

CNC machining. Its versatility and desirable properties extend its application across various

industries, including plumbing, electrical, and medical.

Brass offers impressive durability and is favored for its ease of workability.

Its adaptability and simplicity in machining make it a prevalent choice for producing parts

across a wide range of applications.

| Common Brass Materials | |

| No. | Properties |

| Brass C3600 | It has superior machinability, thread rolling and knurling characteristics. Typically used in the manufacture of fluid connectors, threaded inserts, couplings, and more. |

| Brass C3602 | It’s strength and resistance to corrosion with properties closely resembling that of steel. It is ideal for some of the most demanding conditions such as heavy industrial parts. |

| Brass C3604 | It is used in the mass production of brass components. It is widely used in manufacturing hardware, connector, flange and other machine parts by lathe and CNC. |

| Brass C4926 | A low leaded free cutting brass which conform RoHs and Reach environment regulations. Widely used on electronic parts, precision machine, valves, and related parts. |

Brass Finishing and Post-Processing

360 Brass has a shiny yellow finish that varies depending on surface roughness.

It can be hand-polished to increase its sheen, or media blasted for more of a matte texture.

| Name | Machining Marks |

| As machined | Visible, light surface scratches |

| Smooth machining | Visible, light surface scratches |

| Fine machining | Slightly visible |

| Polishing | Removed on primary surfaces |

| Bead blasting | Removed for non-cosmetic, removed on primary surfaces for cosmetic |

| Brushing | Reduced for non-cosmetic, removed on primary surfaces for cosmetic |

| Powder coating | Removed |

| Black oxide | Visible |

Applications of CNC Brass Parts

The following industries gain the most from CNC machining:

1. Medical 2. Electronics 3. Publishing

4. Transportation 5. Woodwork 6. Construction

7. Agriculture 8. Aerospace 9. Manufacturing

10. Automotive 11. Firearms 12. Metalwork

Company Profile

FAQ's

1. Is brass easier to machine than aluminum?

Brass is considered one of the most machinable materials, particularly when compared to aluminum.

While aluminum can often cause tools to stick, brass tends to have less adhesion to machining tools

during the process.

This metal alloy, comprised of copper and zinc, is extensively used worldwide, yet its full potential

in machining remains underutilized in the United States.

2. Which Brass Material Is Suitable for Machining?

Our CNC machining services utilize Brass C360, a highly machinable alloy known for its

excellent tensile strength, inherent corrosion resistance, and suitability for low-friction applications.

3. What Is the Cost of CNC Machining Brass?

The cost of CNC machining Brass varies depending on factors like the part's complexity, size,

and the specific Brass material used. These factors impact the type of machine required, production

time, and raw material costs.

4. Do you offer other services, like finishing, assembly, packaging, and logistical support?

We provide a wide range of services to meet your needs, from finishing and assembly to packaging

and logistics support.

Our capabilities encompass anodizing, plating, grinding, finishing, assembly, warehousing, packaging,

and just-in-time delivery.

Our aim is to offer a streamlined, all-in-one production process that not only saves you time and

money but also allows you to concentrate on your core business activities.

|