| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | CNC Machining Service |

|---|---|

| Brand Name: | Yexin |

| Model Number: | A7 |

| Certification: | ISO9001:2015 |

| Place of Origin: | Dongguan, China |

| MOQ: | 1 pcs |

| Price: | Negotiable |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, Paypal |

| Supply Ability: | 150000 pcs/month |

| Delivery Time: | 3-10 work days |

| Packaging Details: | Standard Export Carton, Wooden Case, etc. |

| Application: | Medical, Construction, Agriculture, Aerospace, Manufacturing, Automotive, Firearms, etc. |

| Material: | Stainless Steel, Aluminum, Brass, Plastic, Mild steel, Titanium, Wood, Copper, etc. |

| Processing: | Turning, Milling, Broaching, Drilling, Wire EDM, Rapid Prototyping, etc. |

| Service: | OEM, ODM, Customized |

| Surface Finish: | Polishing, Painting, Anodizing, etc. |

| Tolerance: | ±0.01mm, ±0.005mm, etc. |

| Drawing Format: | CAD, PDF, DWG, STEP, STP, IGES, IGS, SLDPRT, 3DM, SAT, etc. |

| Equipment: | CNC Machining Centers |

| Keywords: | CNC Machining Service |

| Company Info. |

| Dongguan Yexin Intelligent Technology Co., Ltd. |

| Verified Supplier |

| View Contact Details |

| Product List |

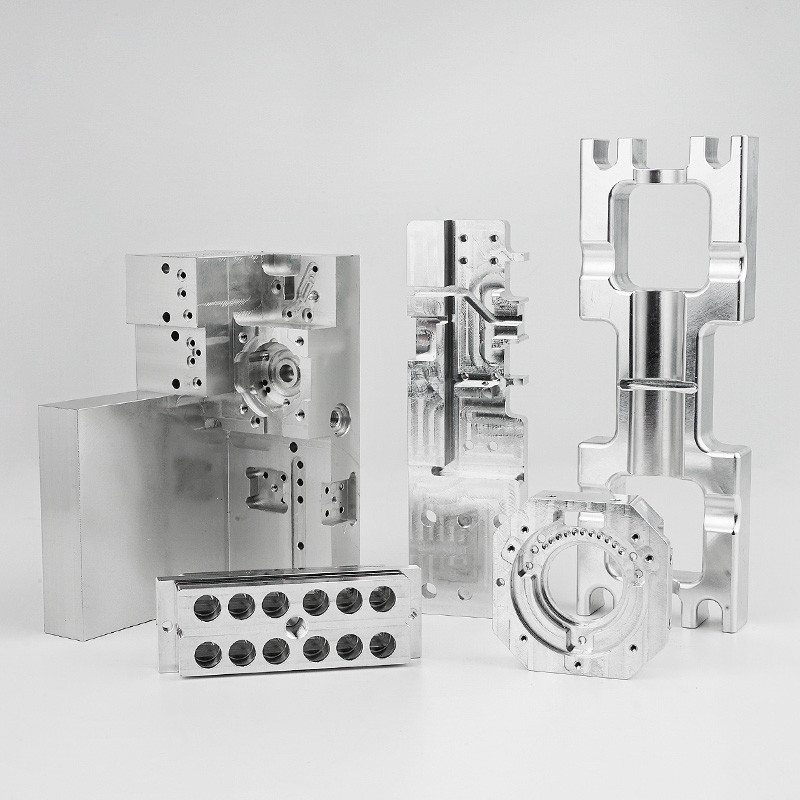

CNC Milling Machining Aluminum Service CNC Customized Part CNC Fabrication

Machining Parts Stainless Steel Turning Parts

CNC machining, short for computer numerical control machining, is a subtractive manufacturing

technique that utilizes computerized controls and machinery to selectively remove material layers

from a solid block.

Precise cuts in the material are orchestrated through programmed instructions, allowing automated

machinery to execute the machining tasks with accuracy and efficiency.

Product Details

CNC milling encompasses a wide range of materials, primarily categorized into three major

groups: plastics, soft metals, and hard metals.

These materials include aluminum, bronze, copper, ceramics, plywood, steel, stone, wood,

zinc, and numerous others. The choice of material depends on ease of workability and desired

properties, with those offering favorable characteristics often being preferred in CNC milling

applications.

Here is a comprehensive overview of the most popular materials

| The Most Popular Materials | |

| Material | Characteristics |

| Aluminum 6061 | Good strength-to-weight ratio, excellent machinability, low hardness |

| Stainless Steel 304 | Excellent mechanical properties, resistant to corrosion & acid, relatively difficult to machine |

| Brass C360 | High ductility, excellent machinability, good corrosion resistance |

| Copper | Excellent thermal and electrical conductivity |

| Titanium | Excellent strength to weight ratio, used in aerospace, automotive and medical industries. |

| ABS | Excellent impact resistance, good mechanical properties, susceptible to solvents |

Nylon (PA6 & PA66) | Excellent mechanical properties, high toughness, poor moisture resistance |

| POM (Delrin) | High stiffness, excellent thermal & electrical properties, relatively brittle |

Surface Finishing

We specialize in the production of custom-made products and offer surface treatment services

tailored to meet our customers' specific requirements and industry standards.

Our comprehensive solutions are both efficient and cost-effective, making us a one-stop destination

with the capacity and capability to provide integrated services.

| Surface Finishing Options for CNC Machining | ||

| Name | Applicable Materials | Can be Applied with |

| Alodine | Aluminum | Media Blasting, Tumbling, Type II Anodizing* Type III Anodizing*, Type III Anodizing with PTFE* |

| Anodizing | Aluminum | Media Blasting, Tumbling, Alodine* |

| Black Oxide | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

| Electroless Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Electropolishing | Steel, Stainless Steel | — |

| Hand Polishing | Acrylic | Enhanced cosmetic appearance |

| Media Blasting | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Nickel Plating | Aluminum, Steel, Stainless Steel | Media Blasting, Tumbling |

| Passivation | Steel, Stainless Steel | Black Oxide, Electroless Nickel Plating, Zinc Plating, Tumbling, Media Blasting |

| Powder Coating | Aluminum, Steel, Stainless Steel | — |

| Tumbling | Aluminum, Steel, Stainless Steel, Brass, Bronze, Copper | All post processes except Electropolish and Powdercoat |

| Vapor Polishing | CNC Polycarbonate (Clear, Black) | Enhanced cosmetic appearance, near optically clear applications |

| Zinc Plating | Steel, Stainless Steel | Media Blasting, Tumbling, Passivation |

Specialist Industries

CNC machining finds extensive applications across various industries.

It is prevalent in aerospace, automotive, consumer electronics, robotics, agriculture,

and numerous sectors that heavily rely on metal components.

Furthermore, CNC machining is widely employed in the medical device industry, household

products manufacturing, energy sector, oil and gas industry, and various consumer-oriented

applications.

It stands as one of the most prevalent and versatile manufacturing processes globally.

Company Profile

Factors Affecting Machining Costs

The cost of CNC machining projects is influenced by various factors

that have a significant impact

on the overall cost calculation.

Manufacturers looking to optimize their processes and manage expenses effectively should have

a thorough understanding of these key elements that determine machining costs.

Let's delve into the factors that play a crucial role in determining the cost of CNC machining:

1. Material Selection:

The choice of raw material directly affects machining costs.

Different materials come with varying costs, availability, and machining characteristics.

High-performance alloys, for instance, may be more expensive than common metals.

Material availability also affects pricing. When calculating machining expenses, it's essential to

consider the type of material required for CNC machined parts and its associated cost.

2. Complexity of Design:

The complexity of the machined part or component is a significant

cost determinant.

Parts with intricate features, tight tolerances, and complex geometries often necessitate advanced

machining techniques, specialized tooling, and longer machining time.

These factors increase overall costs due to the additional precision and expertise required to

produce such complex components.

3. Machining Time:

Machining time is a critical factor in CNC cost calculation. The

longer it takes to machine a part,

the higher the cost.

Machining time includes cycle time (the time spent cutting the part), setup time (preparation and

tool changes), and overall production efficiency.

Optimizing machining processes to reduce cycle time and enhance setup efficiency can minimize

costs and boost productivity.

4. Machine Tooling:

The choice and management of machine tooling have a significant

impact on machining costs.

Considerations should include tooling costs, encompassing the purchase, maintenance, and

replacement of cutting tools.

The lifespan of cutting tools and the time required for tool changeovers affect production

efficiency and, consequently, cost.

Proper selection, maintenance, and optimization of machine tooling can help control expenses

in CNC machining.

5. Volume and Batch Size:

Production volume and batch size directly influence machining

costs.

Economies of scale come into play with larger volumes. The cost per part typically decreases

as production quantities increase.

However, it's crucial to strike a balance between volume and setup time. Small batch sizes may

have higher costs per part due to increased setup time, while larger volumes benefit from reduced

setup time and lower costs per part.

6. Labor Costs:

Labor costs, encompassing the wages of CNC machining engineers and

operators, make a

significant contribution to CNC machining expenses.

Skilled operators with expertise in CNC programming, setup, and operation are essential for

efficient and accurate machining.

Labor-intensive operations or intricate part requirements may involve additional labor costs.

Finding the right balance between utilizing skilled labor and cost management is crucial in

controlling machining expenses.

7. Overhead Costs:

Overhead costs associated with CNC machining operations can impact

the overall cost calculation.

These costs include facility expenses, utilities, administrative costs, quality control, and inspection.

Managing and optimizing these overhead expenses are vital for cost control and maintaining a

competitive edge in CNC machining.

8. Scrap and Rework:

Scrap and rework costs are important considerations in machining

expenses.

Material wastage due to errors or deviations from specifications can significantly increase costs.

Minimizing scrap through effective quality control measures, precision machining techniques,

and robust inspection processes helps reduce material waste and the need for rework, ultimately

lowering overall machining costs.

By comprehending and analyzing these factors that affect machining costs, manufacturers can

identify areas for improvement, implement cost-saving strategies, and optimize their CNC machining

processes to achieve greater efficiency and profitability.

|