| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vibrating Fluidized Bed Dryer |

|---|---|

| Brand Name: | WKS |

| Model Number: | WKS-FBD-6*0.6 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 10 SETS PER MONTH |

| Delivery Time: | about 30 working days |

| Packaging Details: | normally it is packed in the plywood case, or loaded directly in the container after film wrapping |

| Name: | Vibrating Fluidized Bed Dryer |

| Capacity: | 100-130kg/h water evaporation |

| Heat source: | Gas or electric or steam heating |

| Application: | chemical, pharmaceutical, food, dehydrated vegetables, food, minerals and other industries powder, granular materials, dry, cooling and other operations |

| Warranty: | 1 Year |

| Condition: | New |

| Voltage: | 220v-450v |

| Type: | Fluid Bed Drying Equipment |

Stainless steel vibrating fluidized bed dryer nutrition powder production equipment

Vibrating Fluidized Bed Dryer

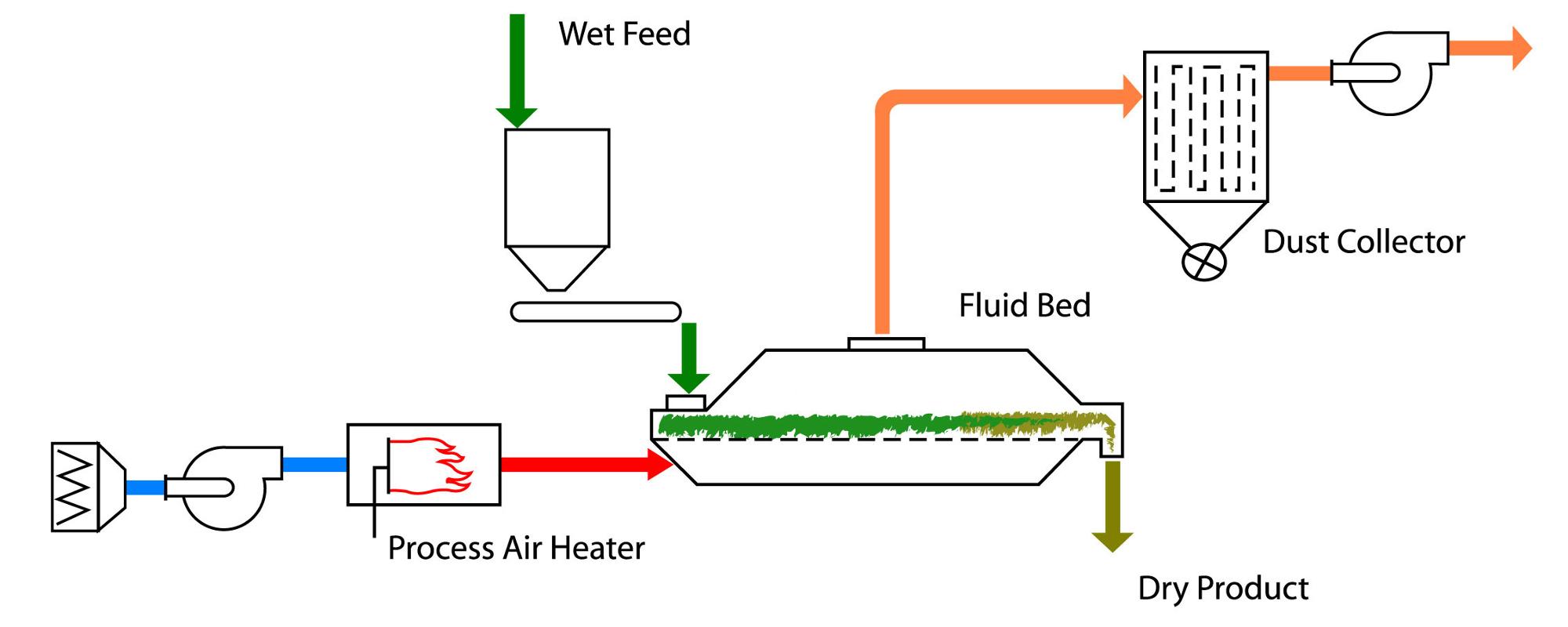

Through operation and improvement for twenty years, it has play an active part in the fields of pharmaceutical, chemical, foodstuff industries, grain processing and so on. It consists of air filter, fluid bed, cyclone separator, bag filter, high speed centrifugal fan, operation table and so on. Because of the different raw material property, it is necessary to equip dust remover in accordance with particle needs. It may select cyclone separator and bag filter at the same time or one of them. In general speaking, cyclone separator can be selected if the raw material is large and bag filter may be selected if raw material is light. Moreover, there is feeding device for your selection.

Clean and hot air enters into fluid bed through distributor of valve plate. The wet raw material fed from feeder forms the boiling state by hot air. Because of the wide contact between hot air and raw materials, drying time is short. The air enters from front of bed, boiling in bed for several minutes, and discharged from other side of bed. The machine works in negative pressure.

Technical parameters

| Model | Area of fluidi bed(㎡) | Temperature of inlet air(℃) | Temperature of outlet air(℃) | Water evaporation capacity (kg/h) | Motor Power(kW) | Weight (kg) |

| WKS-FBD-3*0.3 | 0.9 | 70-140 | 40-70 | 20-35 | 0.8*2 | 1250 |

| WKS-FBD-4.5*0.3 | 1.35 | 70-140 | 40-70 | 35-50 | 0.8*2 | 1250 |

| WKS-FBD-4.5*0.45 | 2.025 | 70-140 | 40-70 | 50-70 | 1.1*2 | 1670 |

| WKS-FBD-4.5*0.6 | 2.7 | 70-140 | 40-70 | 70-90 | 1.1*2 | 1670 |

| WKS-FBD-6*0.45 | 2.7 | 70-140 | 40-70 | 80-100 | 1.5*2 | 2100 |

| WKS-FBD-6*0.6 | 3.6 | 70-140 | 40-70 | 100-130 | 1.5*2 | 2400 |

| WKS-FBD-6*0.75 | 4.5 | 70-140 | 40-70 | 120-140 | 2.2*2 | 2840 |

| WKS-FBD-6*0.9 | 5.4 | 70-140 | 40-70 | 140-170 | 2.2*2 | 3160 |

| WKS-FBD-7.5*0.75 | 5.625 | 70-140 | 40-70 | 150-180 | 2.2*2 | 3200 |

| WKS-FBD-7.5*0.9 | 6.75 | 70-140 | 40-70 | 160-210 | 3.0*2 | 3600 |

Brief drawing

Equipment working principle

WKS series of vibration fluid bed dryer is a continuous drying

equipment for non-sticky particles. Its working principle is: cold

air is filtered through the filter, and then goes into the heater,

and is heated to a certain temperature, then hot air is distributed

into the lower bed via multiple inlets and flows up through

perforated plate of the bed. Material goes evenly into the bed

through screw feeder, under the action of the vibration force, the

material moves up forward continuously along the horizontal

direction, while undergoes heat exchange with the hot air coming up

from bottom, the moisture of material is evaporated rapidly, and

the wet air is discharged from the exhaust fan, and the material is

fully dried and discharged from the discharge port.

Equipment characteristics

1. the equipment drying time is short, only takes about 6 minutes

for the whole drying process, the general effective ingredients

will not be destroyed.

2. adjustable weir plate is set at the discharge port, by adjusting

the height of the weir plate, you can control stayed drying time of

the material so as to make sure that final water content of

materials meets the requirements.

3. perforated plate adopts back pressure process to ensure flatness

of perforated plate, to avoid the deadline in the process of

material running.

Application

Industrial vibration fluidized bed dryer applicable to chemical,

pharmaceutical, food, dehydrated vegetables, food, minerals and

other industries powder, granular materials, dry, cooling and other

operations.

Such as: citric acid, monosodium glutamate, borax, ammonium

sulfate, compound fertilizer, radish l, silk, soybean meal, lees,

seeds, slag, sugar.

|