| Sign In | Join Free | My frbiz.com |

|

| Sign In | Join Free | My frbiz.com |

|

| Categories | Vibrating Fluidized Bed Dryer |

|---|---|

| Brand Name: | WKS |

| Model Number: | WKS-FBD-6*0.6 |

| Certification: | CE |

| Place of Origin: | CHINA |

| MOQ: | 1 |

| Price: | Negotiable |

| Payment Terms: | T/T |

| Supply Ability: | 10 SETS PER MONTH |

| Delivery Time: | about 30 working days |

| Packaging Details: | normally it is packed in the plywood case, or loaded directly in the container after film wrapping |

| Name: | Vibrating Fluidized Bed Dryer |

| Capacity: | 100-130kg/h water evaporation |

| Heat source: | Gas or electric or steam heating |

| Application: | chemical, pharmaceutical, food, dehydrated vegetables, food, minerals and other industries powder, granular materials, dry, cooling and other operations |

| Warranty: | 1 Year |

| Condition: | New |

| Voltage: | 220v-450v |

| Type: | Fluid Bed Drying Equipment |

Vibrating fluidized bed drying equipment for dihydro-ammonia granules

Vibrating Fluidized Bed Dryer

Raw material is heated evently and heat exchange is fully used and dry capacity is high. Compared with ordinary drier, the energy can be saved about 30%. The vibration is created by motor. It is stable in peration and convenient in maintenance, low noise and long life. The fluidezed state is stable and no dead angle and phenomenon of broken out; It is good in regulation and wide in suitablity. The thinckness of raw material layer and movable speed insode the machine and the amlitude can be adjusted through continous variable speed. It is small for damaging the surface of raw material. The equipment can be used for drying raw materials that are easy broken. The drying effect can not be affected even if raw materials have anomaly shape; It is effective to prevent from cross pollution between raw material and air because the quipment adapts fully closed structure. The environment of operation is clean.

Technical parameters

| Model | Area of fluidi bed(㎡) | Temperature of inlet air(℃) | Temperature of outlet air(℃) | Water evaporation capacity (kg/h) | Motor Power(kW) | Weight (kg) |

| WKS-FBD-3*0.3 | 0.9 | 70-140 | 40-70 | 20-35 | 0.8*2 | 1250 |

| WKS-FBD-4.5*0.3 | 1.35 | 70-140 | 40-70 | 35-50 | 0.8*2 | 1250 |

| WKS-FBD-4.5*0.45 | 2.025 | 70-140 | 40-70 | 50-70 | 1.1*2 | 1670 |

| WKS-FBD-4.5*0.6 | 2.7 | 70-140 | 40-70 | 70-90 | 1.1*2 | 1670 |

| WKS-FBD-6*0.45 | 2.7 | 70-140 | 40-70 | 80-100 | 1.5*2 | 2100 |

| WKS-FBD-6*0.6 | 3.6 | 70-140 | 40-70 | 100-130 | 1.5*2 | 2400 |

| WKS-FBD-6*0.75 | 4.5 | 70-140 | 40-70 | 120-140 | 2.2*2 | 2840 |

| WKS-FBD-6*0.9 | 5.4 | 70-140 | 40-70 | 140-170 | 2.2*2 | 3160 |

| WKS-FBD-7.5*0.75 | 5.625 | 70-140 | 40-70 | 150-180 | 2.2*2 | 3200 |

| WKS-FBD-7.5*0.9 | 6.75 | 70-140 | 40-70 | 160-210 | 3.0*2 | 3600 |

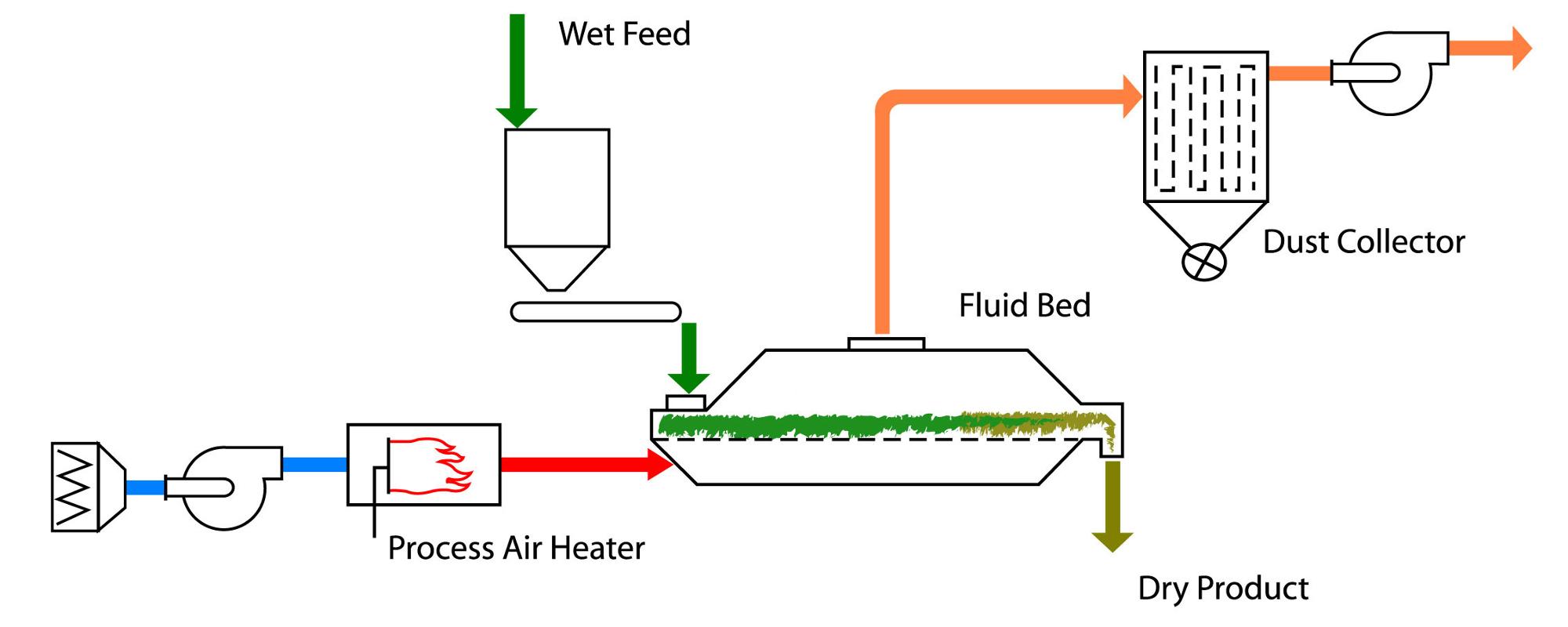

Brief drawing

Principle

|